High-pressure oil-control variable damping absorber

A high-pressure oil and shock absorber technology, applied in the field of hydraulic vibration damping, can solve problems such as high cost and complex structure, and achieve the effects of low cost, large adjustable range and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

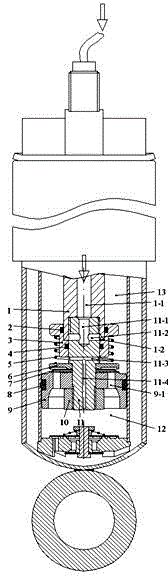

[0028] figure 1 It is an overall schematic diagram of an embodiment of the present invention, which is a double-tube shock absorber. It is worth noting that the core of the present invention lies in the innovation of the piston assembly, which is not only suitable for double-tube shock absorbers, but also suitable for single-tube shock absorbers. Cylinder inflatable shock absorbers, pump shock absorbers and other shock absorbers.

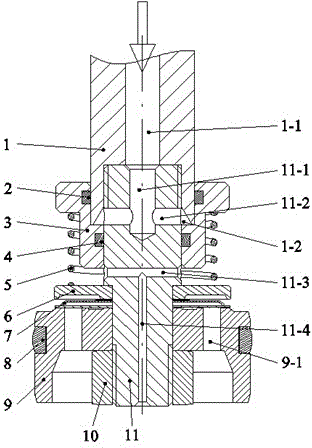

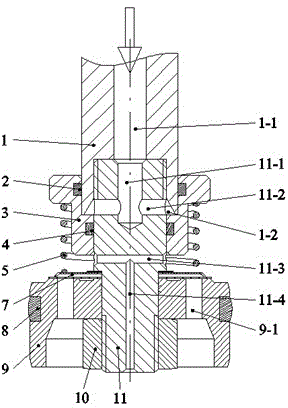

[0029] Such as figure 2 As shown, it is a structural diagram of a piston assembly with a flow valve limit seat of the present invention, which includes a piston rod 1 processed with a piston rod center hole 1-1 and a piston rod end annular cavity 1-2, a piston 9, a fixed connection The spool 11 between the piston rod 1 and the piston 9, the slider 3 slidably connected to the outer surface of the spool 11 and the slider spring 5 set on the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com