Universal type release mechanism

A general-purpose connection board technology, applied in weapon accessories, offensive equipment, weapon testing, etc., can solve the problems of high cost and poor safety, and achieve the effect of low cost, high safety, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

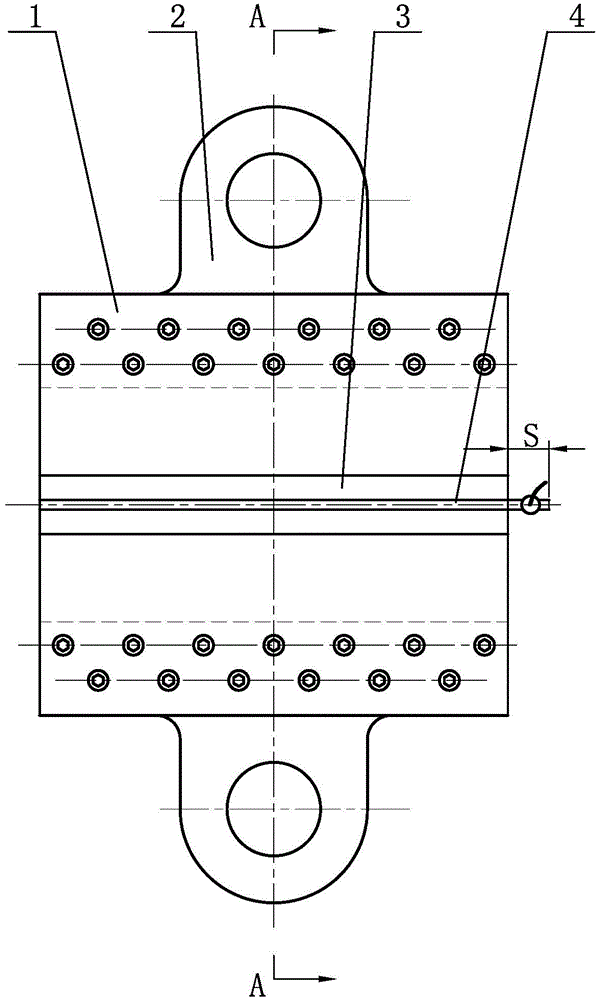

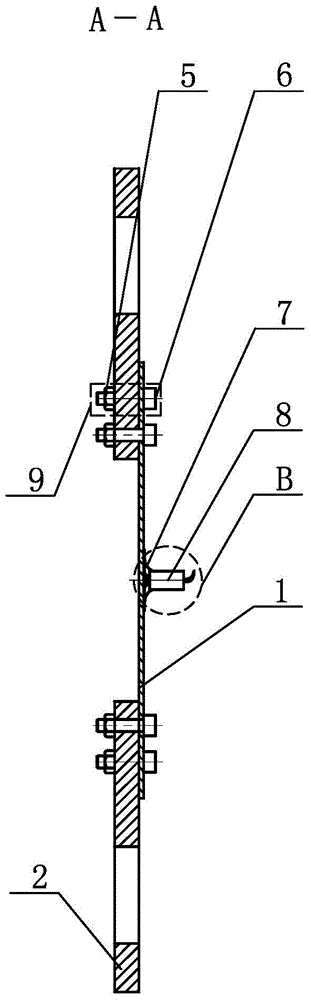

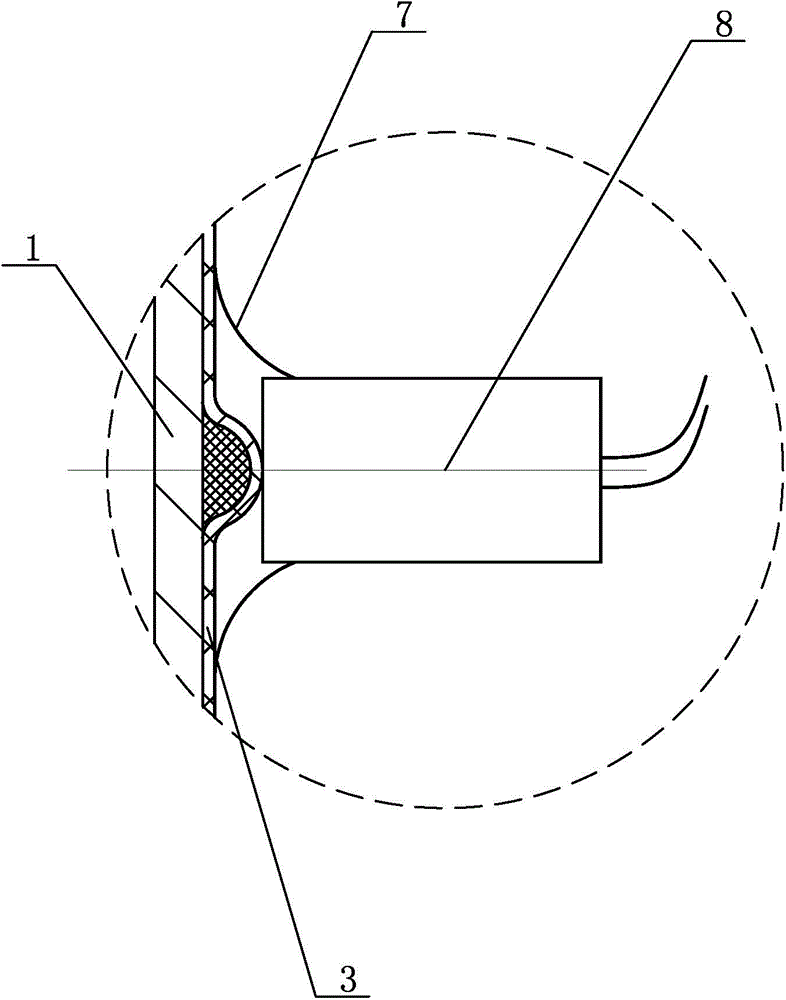

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 3 Explain, the general-purpose release mechanism of this embodiment, the general-purpose release mechanism includes a connecting plate 1, an aluminum foil tape 3, a cutting cable 4, an insulating tape 7, a detonator 8, two connecting rings 2 and a plurality of screw fasteners 9 The connecting plate 1 is vertically arranged, and the two connecting rings 2 and the connecting plate 1 are fastened and connected by a plurality of screw fasteners 9 respectively, and the centerlines of the two connecting rings 2 coincide with the vertical centerline of the connecting plate 1 , the two connecting rings 2 are arranged symmetrically with respect to the transverse centerline of the connecting plate 1, the V-shaped groove of the cutting cable 4 covers the entire horizontal centerline of one side panel of the connecting plate 1, and the detonating end of the cutting cable 4 is placed on the connecting plate 1, there is a d...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 and figure 2 It is explained that each connection suspension ring 2 in this embodiment is fastened and connected with the connection plate 1 through 2 to 13 screw fasteners 9 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 It is explained that 2 to 13 screw fasteners 9 in this embodiment are evenly distributed and fastened on the board surface where the connecting ring 2 and the connecting plate 1 are connected. The overall connection is reliable and stable. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com