Adaptive curvature seal coupling wedge applied to ultrasonic phased array probe

An ultrasonic phased array and self-adaptive technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves. The effect of high noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

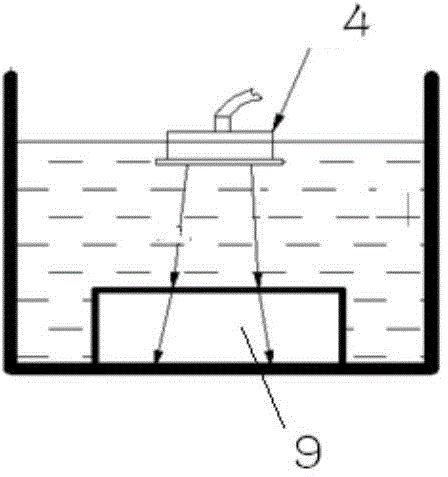

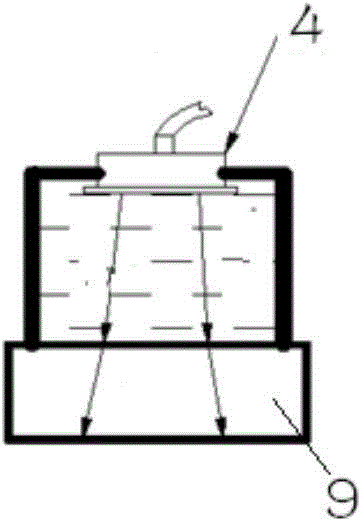

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Such as Figure 3 ~ Figure 5 As shown, the upper and lower surfaces of the wedge body 1 are planes parallel to each other, and a liquid-filled chamber 2 passing through the upper and lower surfaces is processed in the wedge body 1, and the upper end surface of the liquid-filled chamber 2 is processed with a limit platform 3 , the width of the limiting platform 3 is d 2 , the angle between the upper surface of the liquid-filled chamber 2 and the upper surface of the wedge is the interface angle α. The liquid-filled chamber 2 is in the shape of a hexahedron, the length of the upper end surface is less than or equal to the length of the lower end surface, and the width of the upper end surface is less than or equal to the width of the lower end surface.

[0035] The length of the interface of the limiter 3 is L which is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com