Intelligent four-wire point selection method of PCB electrical performance test point

A technology of electrical performance and test points, which is applied in the field of intelligent four-wire point selection, can solve the problems of wrong point selection and missed point selection, and achieve the effect of test guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

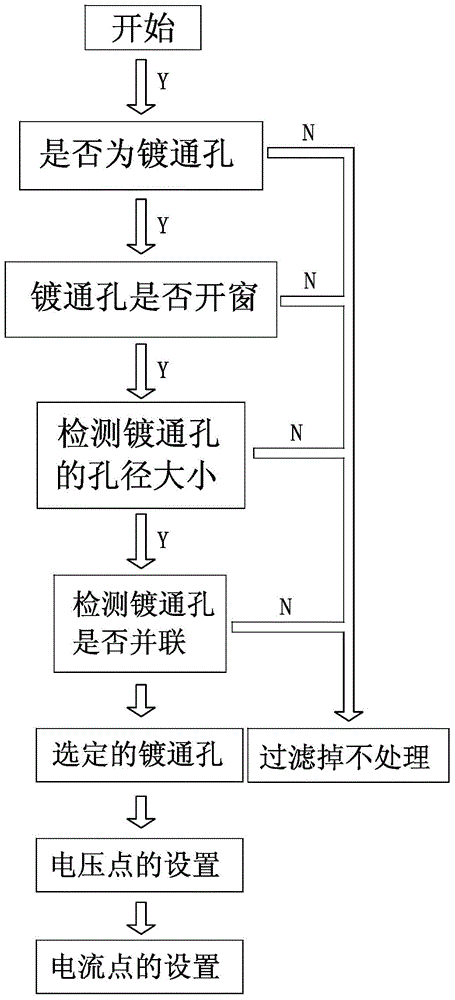

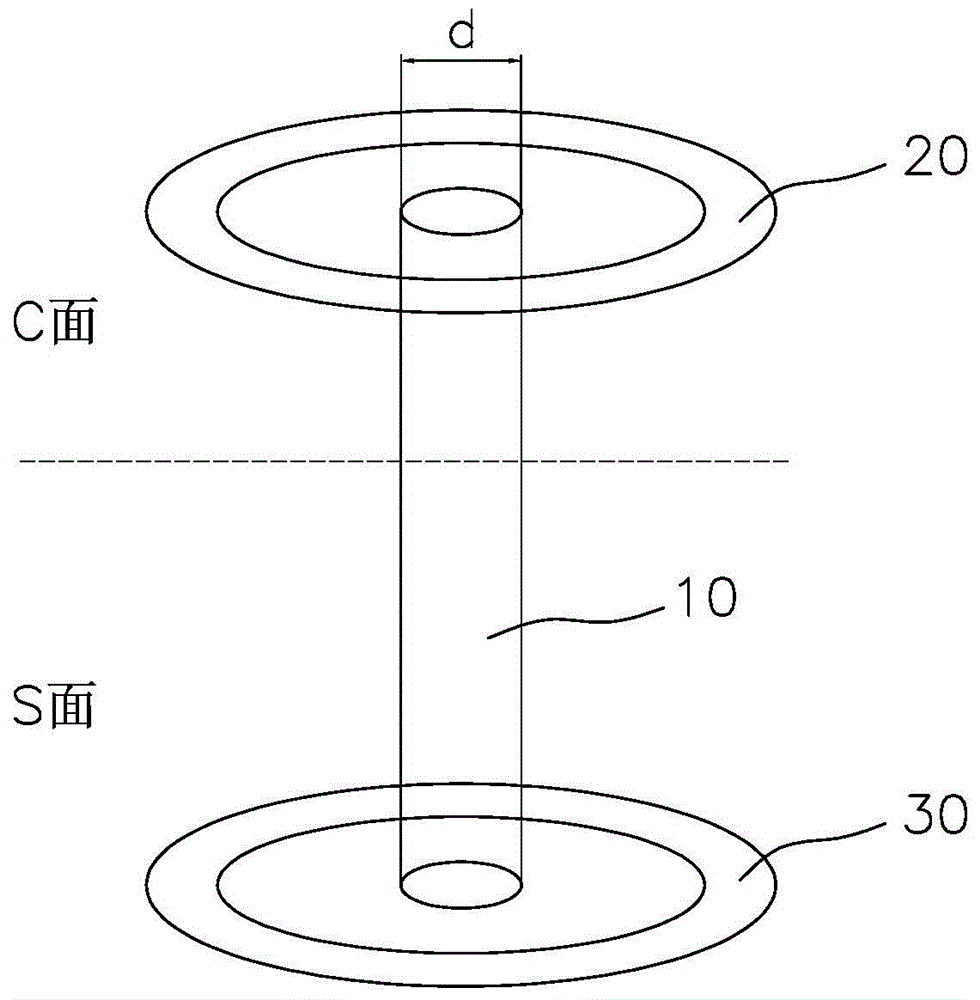

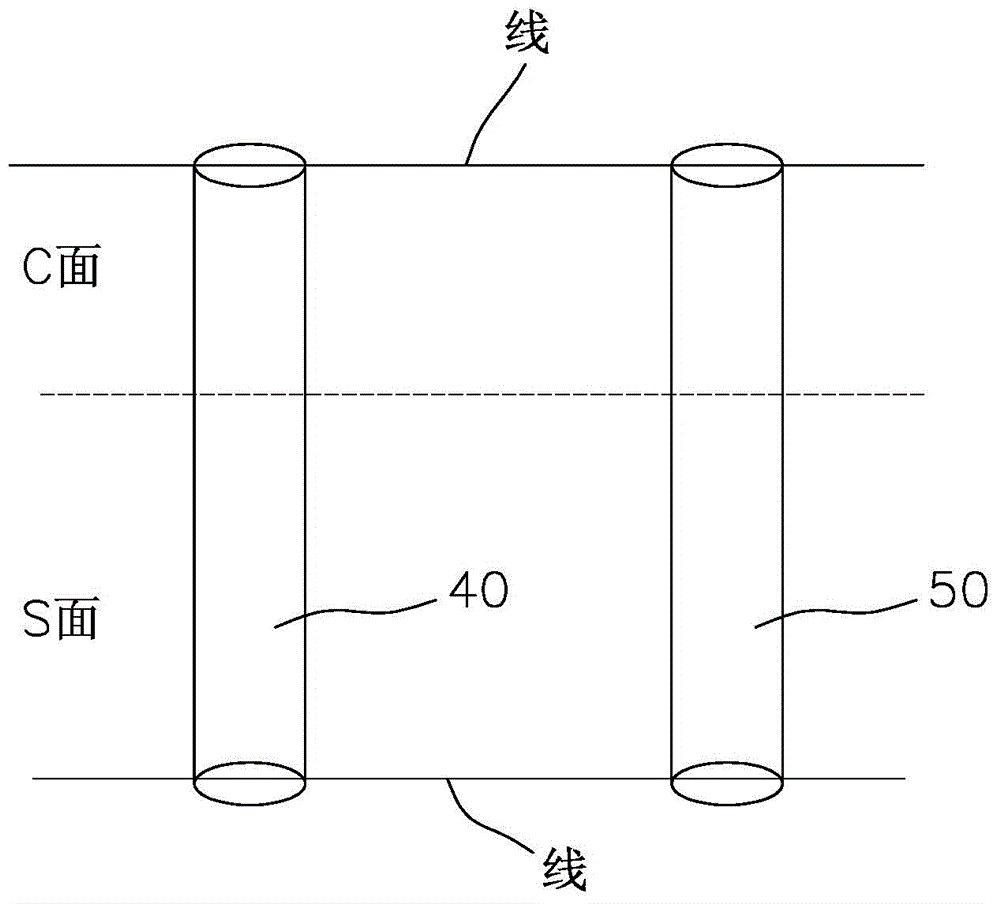

[0022] refer to figure 1 As shown, the present invention discloses an intelligent four-wire point selection method for PCB electrical performance test points, which is used for testing holes on the PCB board. Since in the existing PCB production process, there may be a series of problems such as lack of copper pillars and permeation plating in the produced products, so before conducting electrical performance tests on the PCB, it is necessary to check whether each hole on the PCB is Plating through qualified inspection. In the PCB field, the upper and lower sides of the PCB surface are called the top layer and the bottom layer respectively, the top layer is called the C side, and the bottom layer is called the S side. In this embodiment, an intelligent four-wire point selection method for a PCB electrical performance test point disclosed by the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com