Radio frequency ldmos device and manufacturing method thereof

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as radio frequency performance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

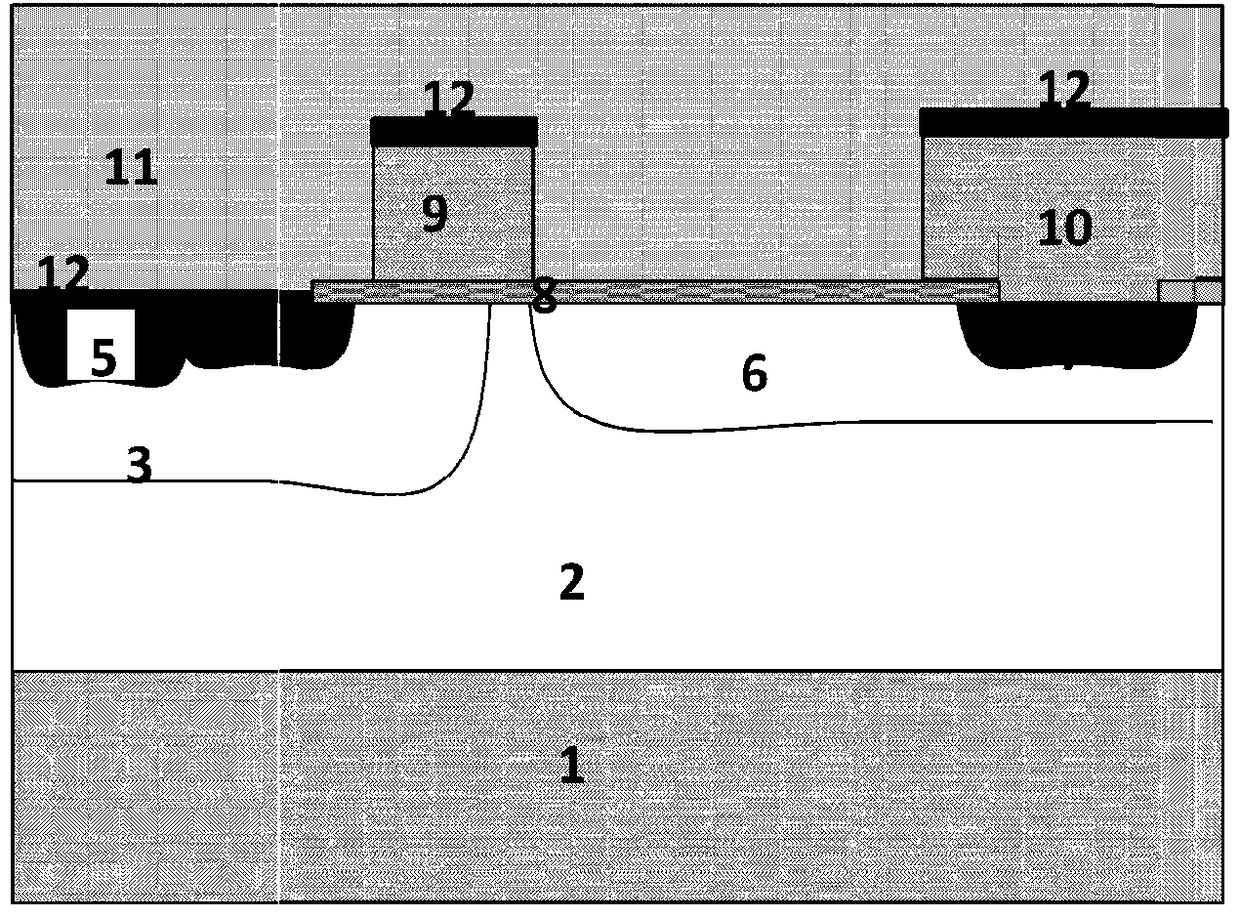

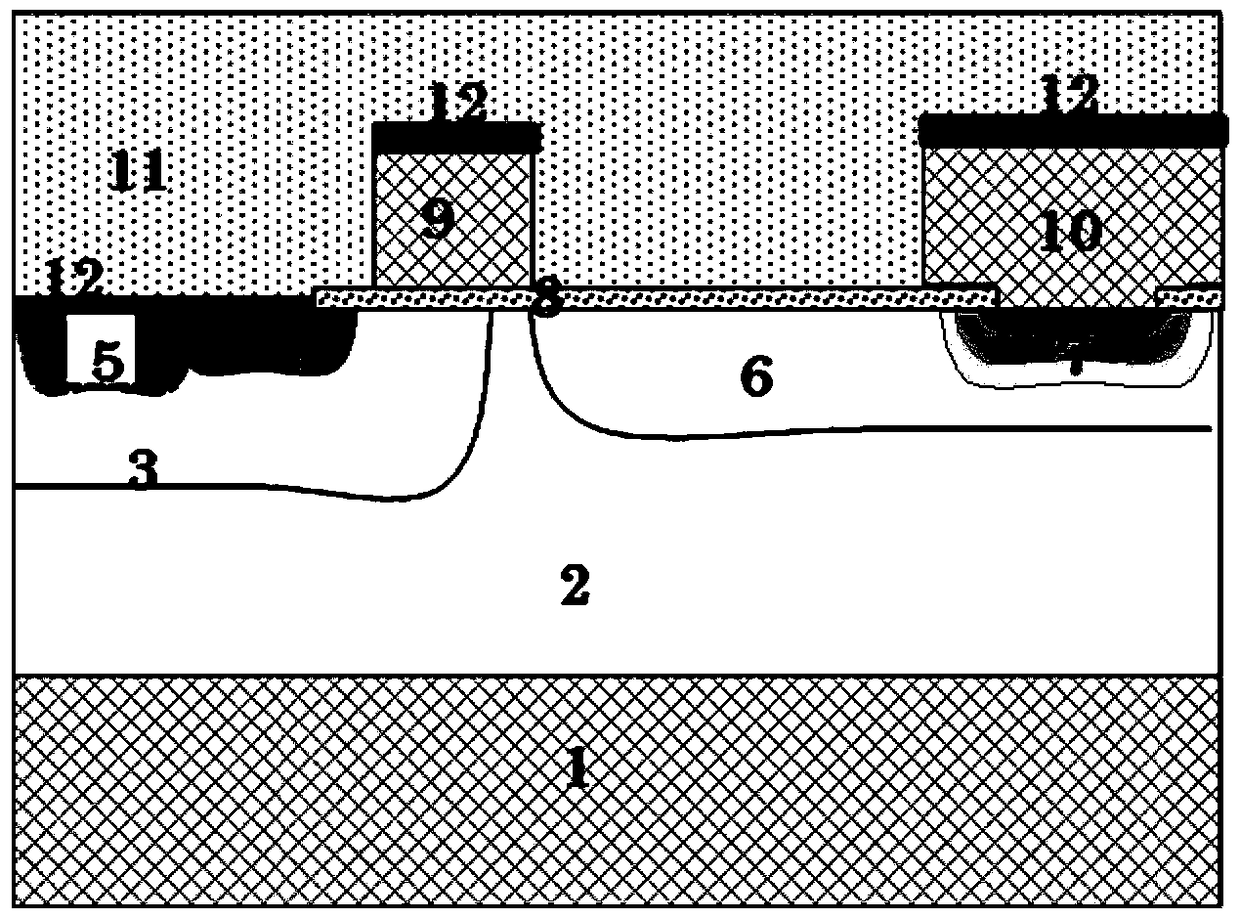

[0027] The first embodiment of the manufacturing method of the radio frequency LDMOS device of the present application includes the following steps:

[0028] Step 1, see Figure 3a , epitaxial growth is carried out on the heavily doped p-type substrate 1 to form a layer of lightly doped p-type epitaxial layer 2 . The thickness of the epitaxial layer 2 is, for example, 3 to 15 μm.

[0029] Then, see Figure 3b , forming a ring of isolation structures 2 a on the epitaxial layer 2 . The isolation structure 2 a is silicon oxide, for example, shallow trench isolation (STI) process and local oxidation (LOCOS) process are used. Device isolation is a routine step, which can be omitted without special introduction, and the following figures only show the region between the isolation structures 2a and omit the isolation structure 2a.

[0030] Step 2, see Figure 3c , performing thermal oxidation growth on the epitaxial layer 2 to form a gate oxide layer 8 . The thickness of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com