Electrode composite material and preparation method thereof, and negative electrode and battery having the electrode composite material

A composite material and electrode technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve the problem of unsatisfactory electrochemical performance, large-scale production of manganese oxide-based electrode materials, etc. problems, to achieve the effect of large-scale production potential, rich modifiable points, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of an electrode composite material, the preparation method comprising the following steps: mixing raw materials, the raw materials include M13 phage suspension and manganese source; adding alkali and hydrogen peroxide solution to the mixture in sequence; storing at 3°C to 5°C; Wash; collect the precipitate; dry the precipitate to obtain M13 phage / Mn 3 o 4 electrode composites.

[0035] An electrode composite including M13 bacteriophage and Mn 3 o 4 , the electrode composite material also includes carbon nanotubes. The addition of carbon nanotubes can significantly improve the capacity and cycle performance of batteries assembled with electrode composite materials. Preferably, the carbon nanotubes are selected from at least one of single-wall carbon nanotubes or multi-wall carbon nanotubes. In electrode composite materials, M13 phage, Mn 3 o 4 And the mass ratio between carbon nanotubes is 9.99:90:0.01.

[0036] A preparation method of an e...

Embodiment 1

[0070] Preparation of electrode composite material: Mix 10 mL of M13 phage suspension with 100 mL of 0.10 M manganese sulfate solution. Then 100 μL of a solution of multi-walled carbon nanotubes (American Nanomaterials, 3% W.W) was added to the above mixture. Stirring was continued at room temperature for 24 hours. After stirring, 10 mL of 2.5 mol / L NaOH solution was added to the mixture, and stirred for 10 seconds. Subsequently, an additional 1.4 mL of 30% hydrogen peroxide solution was added. The resulting solution was stored at 4°C for 1.5 hours. The final product was washed twice with Milli-Q water and collected by centrifugation. The resulting powder was dried at 320 °C for 3 hours to obtain M13 phage / Mn 3 o 4 / carbon nanotube electrode composites.

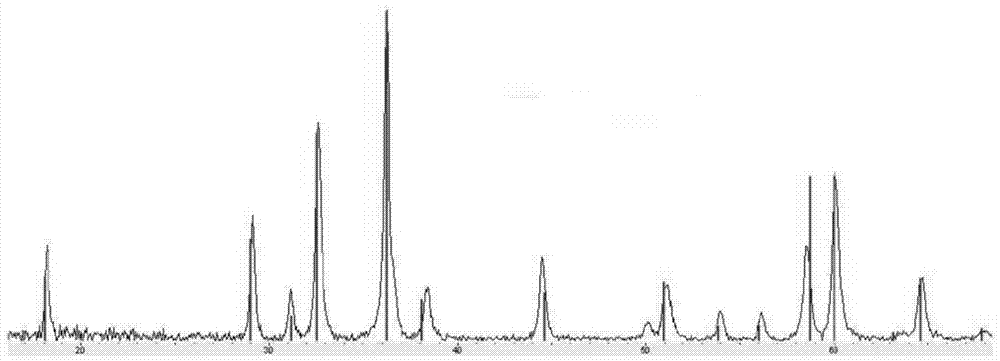

[0071] figure 1 M13 phage / Mn in embodiment 1 3 o 4 / XRD patterns of carbon nanotube electrode composites. The vertical line in the figure corresponds to Mn3 o 4 The standard XRD pattern characteristic peak, from ...

Embodiment 2

[0073] The preparation of negative pole: be the M13 phage / Mn in the embodiment 1 of 70% by weight percentage 3 o 4 / carbon nanotube electrode composite, 10% by weight of polyvinylidene fluoride (PVdF) (Kynar, HSV900) as a binder and 20% by weight of Super Lithium carbon black (MTI, purity 99.5%) was mixed, and N-methyl-2-pyrrolidone (NMP, Sigma company, purity 99.5%) was used as a dispersant to prepare negative electrode slurry. The prepared negative electrode slurry was then coated on copper foil using doctor blade coating. Dry overnight in a vacuum oven at 60° C. to obtain a negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com