Method for measuring crimp height of crimped terminal, measurement device, management method, and management device

A technology for crimping terminals and height measurement, which is applied in measuring devices, mechanical measuring devices, and mechanical devices, etc., and can solve problems such as difficulty in quantitatively measuring the crimping height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

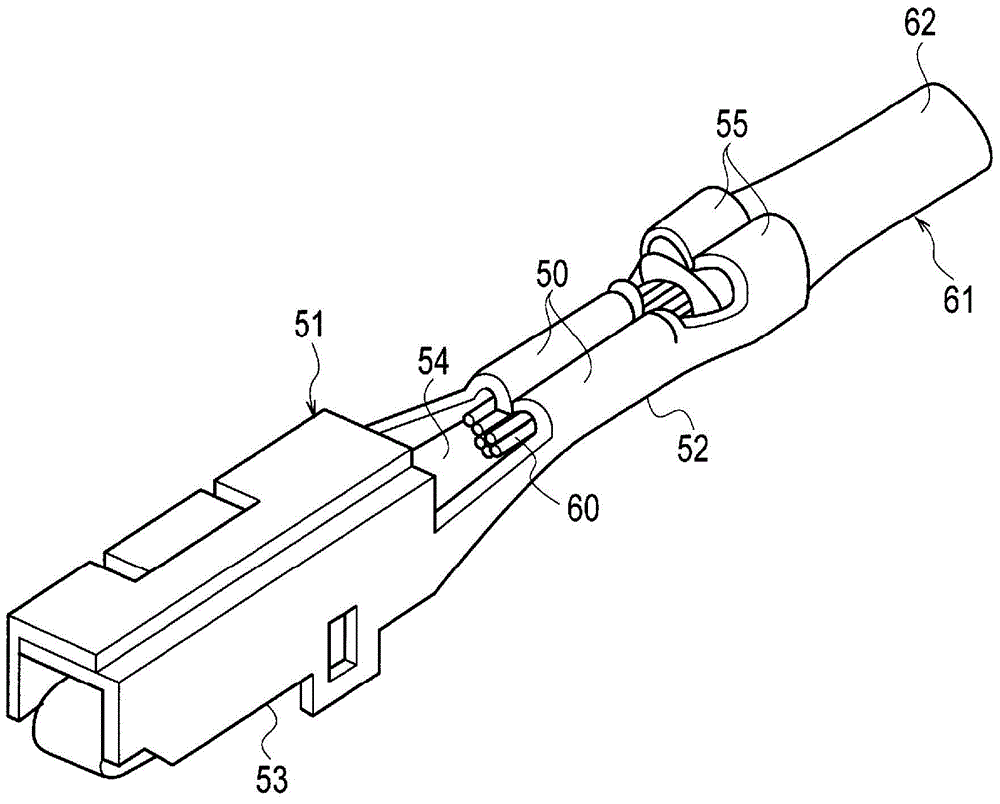

[0060] figure 1 The drawing shows a state where the crimp terminal 51 is crimped and attached to the electric wire 61 by the terminal crimping device 200 . The electric wire 61 includes a conductive core wire 60 and an insulating coating 62 covering the core wire 60 . The core wire 60 is composed of a plurality of bundled conductive wires, and is formed to have a circular cross-sectional shape. The wire constituting the core wire 60 is composed of a conductive metal such as copper, copper alloy, aluminum, aluminum alloy, or the like. The covering 62 is made of synthetic resin. Before the crimp terminal 51 is attached, the electric wire 61 is brought into a state where a part of the coating 62 is removed and the core wire 60 of the part is exposed.

[0061] The crimp terminal 51 is formed by, for example, bending a conductive metal plate. The crimp terminal 51 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com