Concentrated feeding cramming device

A kind of equipment and feeding technology, which is applied in the application, poultry industry, animal husbandry, etc., can solve the problems of operators' fatigue, indigestion, waste of energy, etc., and achieve the goal of improving duck-feeding efficiency, duck-feeding quality, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

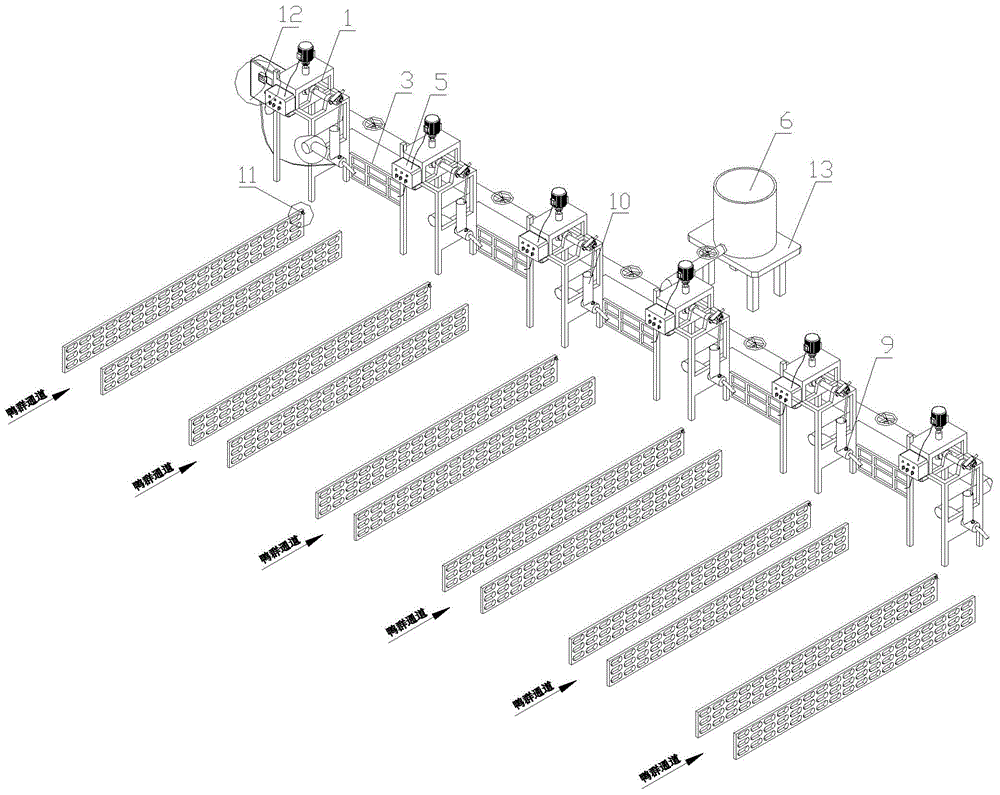

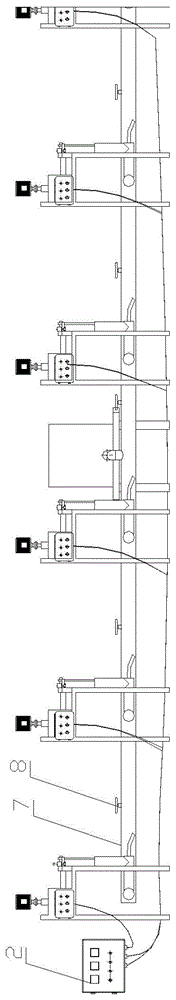

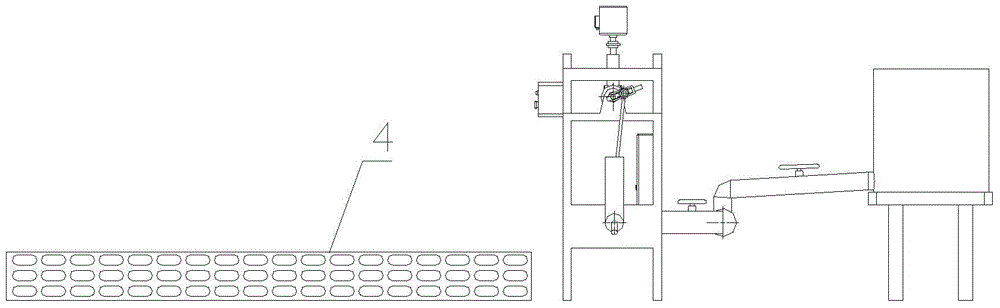

[0021] Embodiment 2 of the present invention: a duck-feeding equipment for centralized feeding, including a duck-feeding machine 1 and a circuit control device 2, two or more duck-feeding machines 1 and barbed wire partitions a3 are arranged in a row at intervals, and barbed wire partitions a3 and duck-feeding Machine 1 divides the space into two areas, one side of the area is provided with two pieces of barbed wire partition column b4, two pieces of barbed wire partition column b4 form a walking passage, one end of the barbed wire partition column b4 is equipped with an infrared induction counter 11, and the other There is a centralized feeding cylinder 6 on the side, and the centralized feeding cylinder 6 is placed on the bracket 13. The centralized feeding cylinder 6 is led directly below the duck filling machine 1 through the pipe 7, and is connected with the extrusion cylinder 10. The extrusion cylinder 10 is fixed. On the duck-feeding machine 1, the extrusion barrel 10 is...

Embodiment 3

[0022]Embodiment 3 of the present invention: a duck-feeding equipment for centralized feeding, including a duck-feeding machine 1 and a circuit control device 2, two or more duck-feeding machines 1 and wooden partitions a3 are arranged in a row at intervals, and wooden partitions a3 and duck-feeding The machine 1 divides the space into two areas. Two wooden partition bars b4 are arranged on one side of the area, and two wooden partition bars b4 form a walking passage. One end of the wooden partition bar b4 is equipped with an infrared induction counter 11, and the other side of the area is equipped with an infrared induction counter 11. There is a centralized feeding cylinder 6 on the side, and the centralized feeding cylinder 6 is placed on the bracket 13. The centralized feeding cylinder 6 is led directly below the duck filling machine 1 through the pipe 7, and is connected with the extrusion cylinder 10, and the extrusion cylinder 10 is fixed. On the duck-feeding machine 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com