Steam wrinkle removal machine

A technology of wrinkle machine and steam, which is applied in the field of steam wrinkle remover, can solve the problem of poor temperature stability of wrinkle removal, and achieve the effect of ensuring stability and fast wrinkle removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

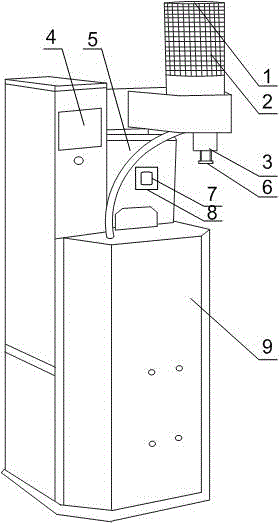

[0017] Such as figure 1 As shown, the present embodiment comprises frame 9, fan and water tank 5, and described fan and water tank 5 are all arranged on the frame 9, and the top of described fan is provided with air inlet 1, and the bottom of fan is provided with air outlet 3 and The pressure roller 6, the pressure roller 6 is placed directly below the air outlet 3, and also includes a digital display thermostat 4 arranged on the frame 9. The air entering through the air inlet 1 and the water in the water tank 5 are mixed with the heated air and water vapor after the heating strip is heated; the mixed gas is sent to the air outlet 3 under the action of the fan. The leather to be wrinkled is placed under the pressure roller 6 at the air outlet 3, and the mixed gas and the pressure roller 6 are used together to quickly smooth the wrinkled leather surface. The digital display thermostat 4 arranged on the frame 9 can precisely regulate the temperature of the heating wire to ensur...

Embodiment 2

[0019] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment is also provided with a sensor 8 and an alarm 7 connected to each other on the water tank 5, the sensor 8 is placed in the water tank 5, and the alarm 7 is placed in the water tank 5 outside. Due to the high requirements of the wrinkle removal process, it takes a lot of time to process and requires a large amount of water in the water tank 5 . When the water level in the water tank 5 was low, the sensor 7 arranged in the water tank 5 transmitted the water level information to the alarm 8, and the alarm 8 sent a prompt alarm in time, and the operator replenished the water in time.

Embodiment 3

[0021] Such as figure 1 As shown, on the basis of Embodiment 1 and Embodiment 2, this embodiment also includes an air filter 2 arranged in the air inlet 1 . When the air is heated, the air filter 2 can filter the air, so that the heated air will not deposit carbon, and prevent black spots from appearing on the leather surface during the ironing and wrinkle removal process of the light-colored leather upper surface.

[0022] Preferably, the fan is a medium-pressure vortex fan. The medium-pressure travel vortex blower outputs strong wind, which drives high-temperature steam to spray on the leather surface, and uses the pressure roller 6 to roll repeatedly to quickly eliminate wrinkles on the leather surface.

[0023] Preferably, the sensor 8 is a BPY800 liquid level sensor. BPY800 is a submersible liquid level sensor, capable of on-site display and remote 4-20mA output, with good stability and reliability, and good water resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com