High Tension Coil Spring Structure for Bed Mattress Having Means for Preventing Friction Noise

A coil spring, high tension technology, applied in the direction of low internal friction springs, mattresses, springs, etc., can solve the problem that the number of exposed wire springs is small, restricting the up and down movement of the exposed wire spring 20, and restricting the elasticity of the exposed wire spring 20 from moving up and down. Quantity and other issues to achieve the effect of improving productivity, improving quality, and increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Reference will now be made in detail to various embodiments of the invention, which are illustrated in the drawings and described below.

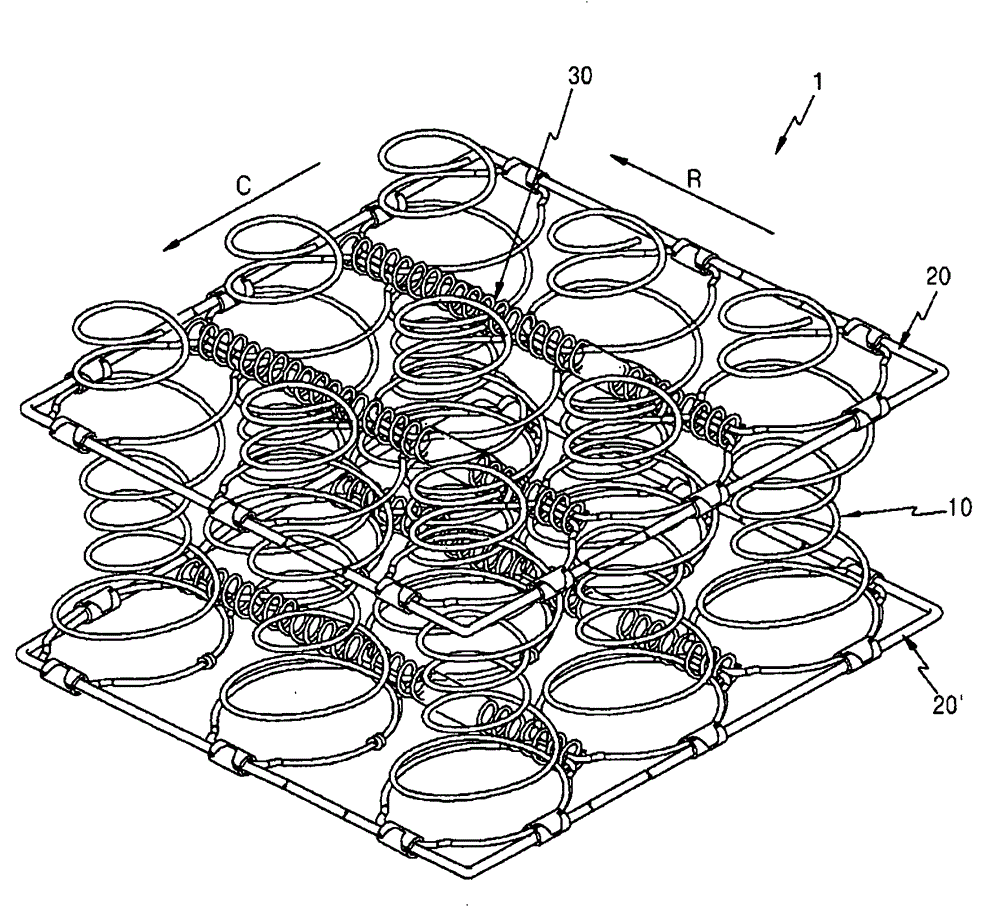

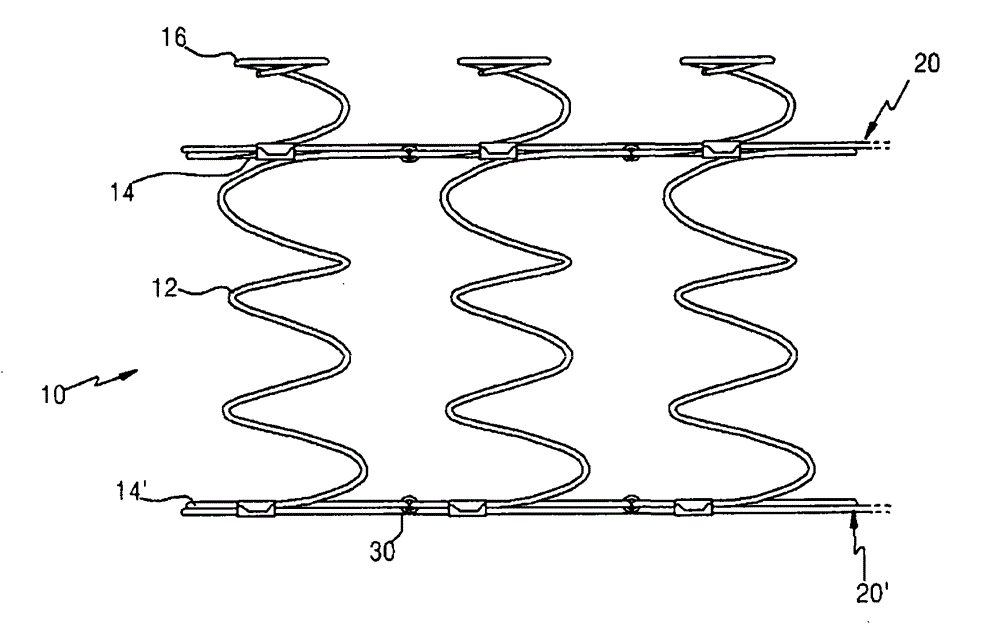

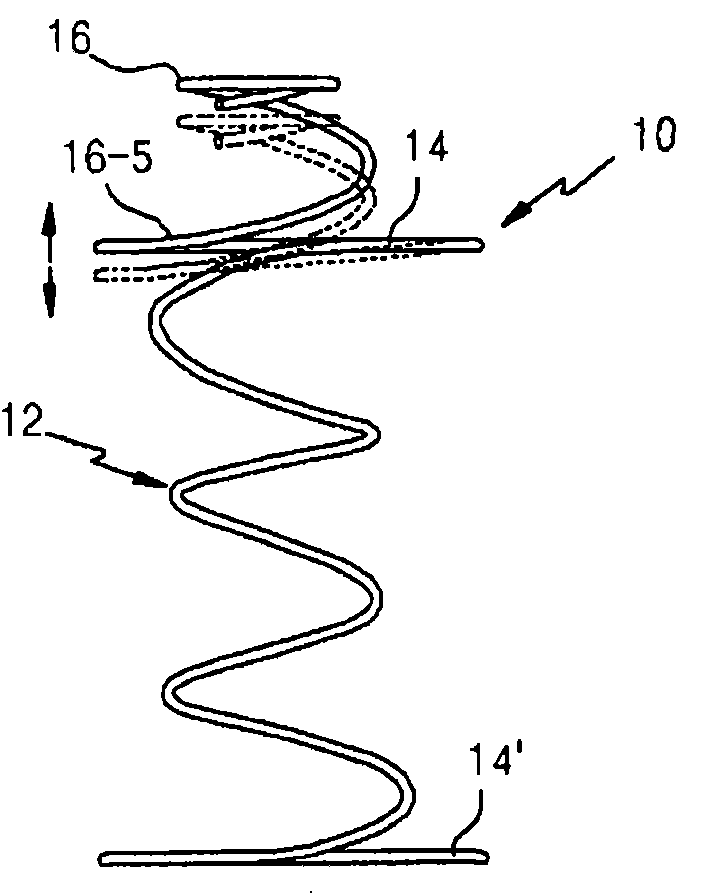

[0048] As shown in Figures 4A to 14B, the present invention provides a high tension coil spring structure for a mattress with means for anti-friction noise. The high-tension coil spring structure includes: a main body winding portion 12, which is neatly arranged in the space between the upper edge member 20 and the lower edge member 20' at a predetermined distance from each other; the upper and lower end winding portions 14 and 14' , they are arranged at the two ends of the main body winding part 12 and are arranged in the range where the upper and lower edge members 20 and 20' are arranged; the upper and lower exposed winding parts 16 and 16', which are wound from the upper and lower ends At least one of 14 and 14' protrudes so as to be exposed from upper and lower edge members 20 and 20'; the enlarged diameter portion A is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com