A Modified Pretreatment Method for Separation of Coal and Rock Components

A technology for coal and rock composition and pretreatment, applied in flotation, solid separation, etc., can solve the problem of poor flotation separation effect, small difference in flotation, and enlarge the difference in flotation between vitrinite and inert group. and other problems, to achieve the effect of increasing the difference in floatability, simple operation, and controllable modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, crushing the raw coal until the particle size is not greater than 0.125mm;

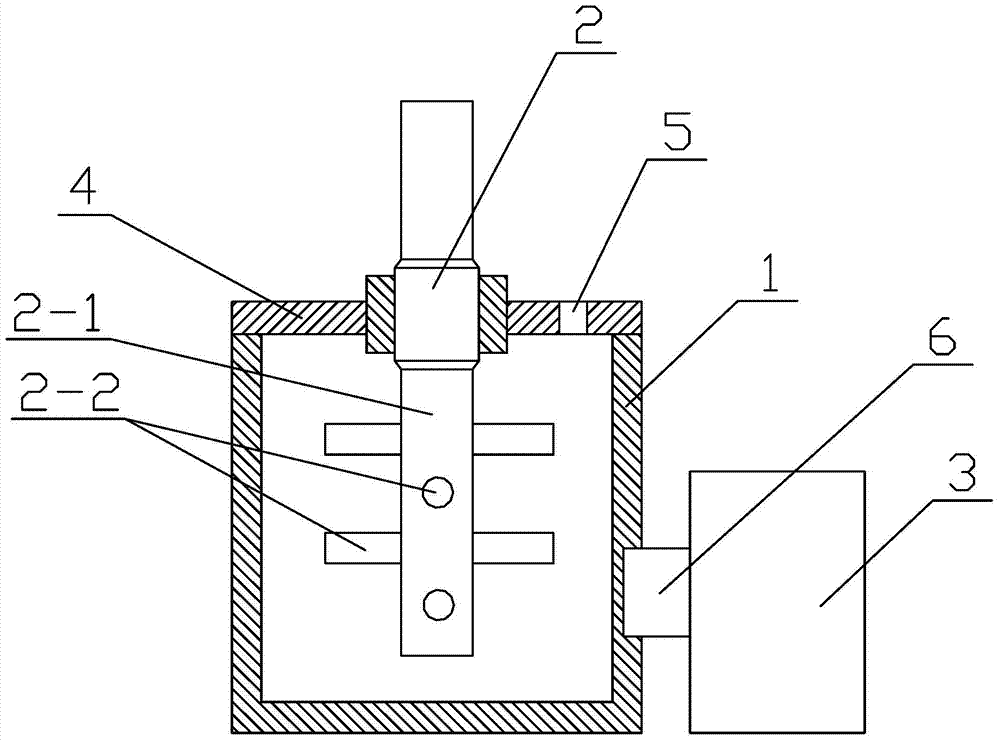

[0031] Step 2, placing zirconia balls with a diameter of 3mm and the crushed raw coal in step 1 in the microwave stirring ball mill of Example 1; the volume ratio of the zirconia balls to the crushed raw coal is 3:1;

[0032] Step 3: Turn on the agitator 2 of the microwave stirring ball mill, and perform ball milling under the condition that the rotating speed is 200rpm. When the agitator 2 is turned on, start to add 1% of the mass of raw coal after crushing into the ball mill barrel 1 through the dosing port 5. % modifying agent methyl alcohol, and control the adding time of the modifying agent to be 1min; after adding the modifying agent for 1min, turn on the microwave generator 3, and under the condition of 550W, microwave radiation to the material in the microwave stirring ball mill for 0.5min, Then close the microwave generator 3;

[0033] Step 4, after closing the microwave gener...

Embodiment 2

[0036] Step 1, crushing the raw coal until the particle size is not greater than 0.125mm;

[0037] Step 2, placing zirconia balls with a diameter of 5mm and the crushed raw coal in step 1 in the microwave stirring ball mill of Example 1; the volume ratio of the zirconia balls to the crushed raw coal is 4:1;

[0038] Step 3: Turn on the agitator 2 of the microwave agitation ball mill, and perform ball milling at a speed of 250 rpm. 10 minutes after the agitator 2 is turned on, start to add in the ball mill barrel 1 through the dosing port 5, which has a mass equal to the quality of the crushed raw coal. 4% modifying agent acetone, and control the adding time of the modifying agent to be 5min; open the microwave generator 3 after adding the modifying agent for 1min, and microwave the material in the microwave stirring ball mill for 2min under the condition that the power is 600W, Then close the microwave generator 3;

[0039] Step 4, after closing the microwave generator 2min i...

Embodiment 3

[0043] Step 1, crushing the raw coal until the particle size is not greater than 0.125mm;

[0044] Step 2, placing zirconia balls with a diameter of 5mm and the crushed raw coal in step 1 in the microwave stirring ball mill of Example 1; the volume ratio of the zirconia balls to the crushed raw coal is 5:1;

[0045] Step 3: Turn on the agitator 2 of the microwave stirring ball mill, and perform ball milling under the condition that the rotating speed is 150rpm. 5 minutes after starting the agitator 2, start to add in the ball mill barrel 1 through the dosing port 5. 5% modified agent ether, and control the adding time of the modified agent to be 5min; after adding the modified agent for 10 minutes, turn on the microwave generator 3, and irradiate the material in the microwave stirring ball mill for 5 minutes under the condition that the power is 450W, Then close the microwave generator 3; continue ball milling until the total time of ball milling reaches 30min;

[0046] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com