Condenser for biological pharmacy

A technology for biopharmaceuticals and condensers, which is applied in centrifuges and other directions to improve cooling efficiency and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

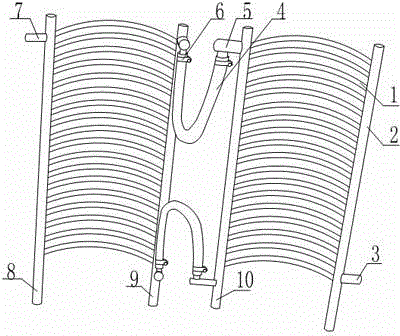

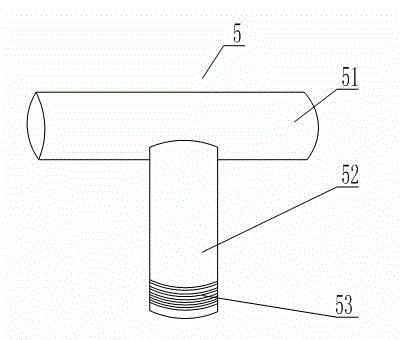

[0021] Such as figure 1 , figure 2 As shown, a condenser for biopharmaceuticals includes condensation column I2, condensation column II8, condensation column III9, condensation column IV10, and several semicircular condensation tubes 1 are arranged between condensation column II8 and condensation column III9. Between the condensation column I2 and the condensation column IV10, there are several semicircular condensation pipes 1. The condensation pipes 1 are made of copper. Both the condensation column III9 and the condensation column IV10 are provided with joints 5. The joints 5 include horizontal shafts 51, A vertical rod 52 perpendicular to the horizontal axis 51, a threaded surface 53 is provided on the outer wall of one end of the vertical rod 52 connected to the connecting pipe 5, and a connecting pipe 4 is provided between the joint 5 on the condensation column III9 and the joint 5 on the condensation column IV10 , the connecting pipe 4 is a PVC hose, the connection be...

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, a condenser for biopharmaceuticals includes condensation column I2, condensation column II8, condensation column III9, condensation column IV10, and several semicircular condensation tubes 1 are arranged between condensation column II8 and condensation column III9. Between the condensation column I2 and the condensation column IV10, there are several semicircular condensation pipes 1. The condensation pipes 1 are made of copper. Both the condensation column III9 and the condensation column IV10 are provided with joints 5. The joints 5 include horizontal shafts 51, A vertical rod 52 perpendicular to the horizontal axis 51, a threaded surface 53 is provided on the outer wall of one end of the vertical rod 52 connected to the connecting pipe 5, and a connecting pipe 4 is provided between the joint 5 on the condensation column III9 and the joint 5 on the condensation column IV10 , the connecting pipe 4 is a corrugated pipe made of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com