Automatic washing production line for plastic boards

An automatic cleaning and plastic plate technology, applied in the directions of drying solid materials, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of poor cleaning effect, waste water and laborious cleaning effect, and simplicity, and achieve the effect of cleaning and sanitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

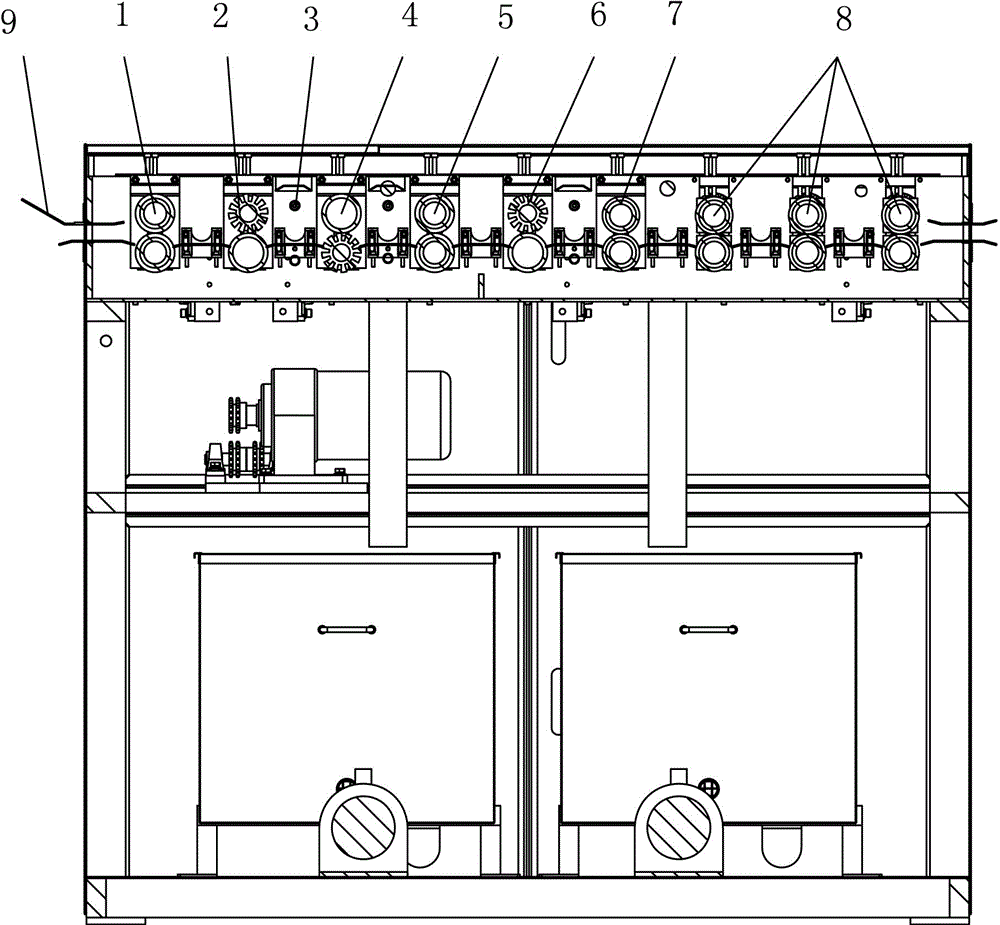

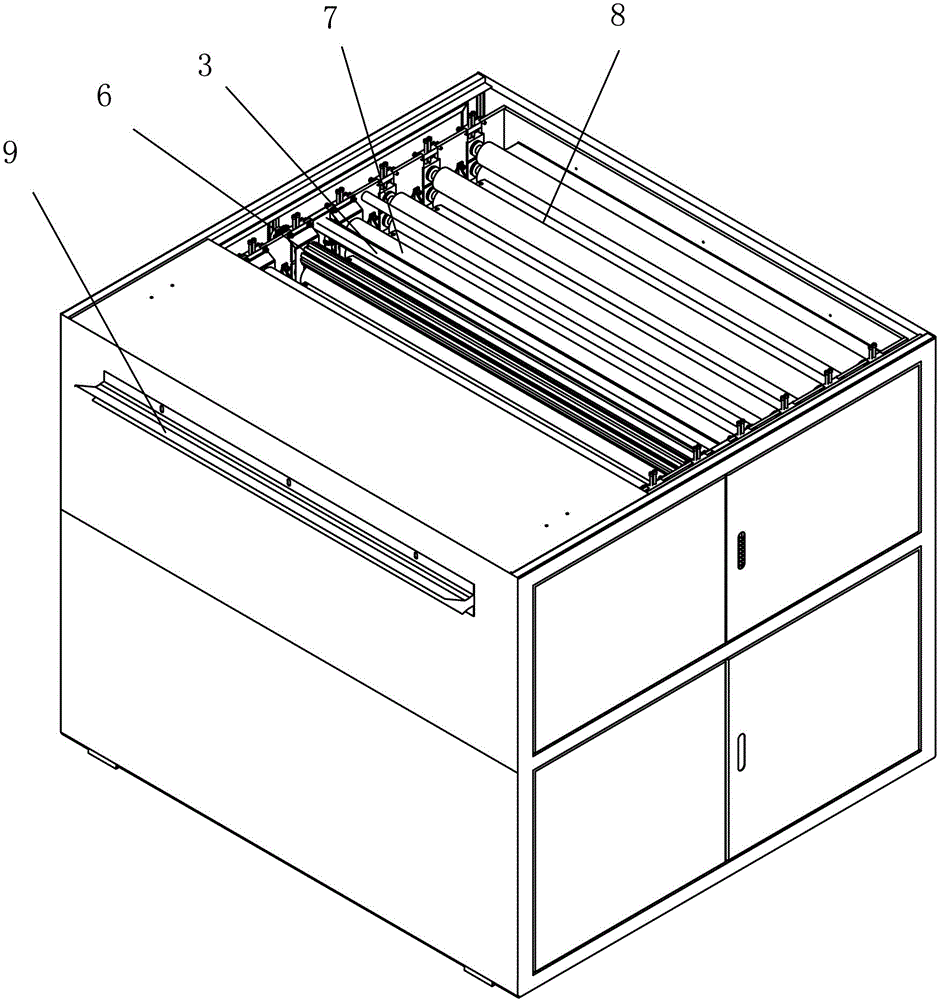

[0017] The following is a detailed description of the embodiments of the present invention by taking the plastic plate automatic cleaning production line model 1450 as an example. The examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or have elements with the same or similar function. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the scope of the present invention.

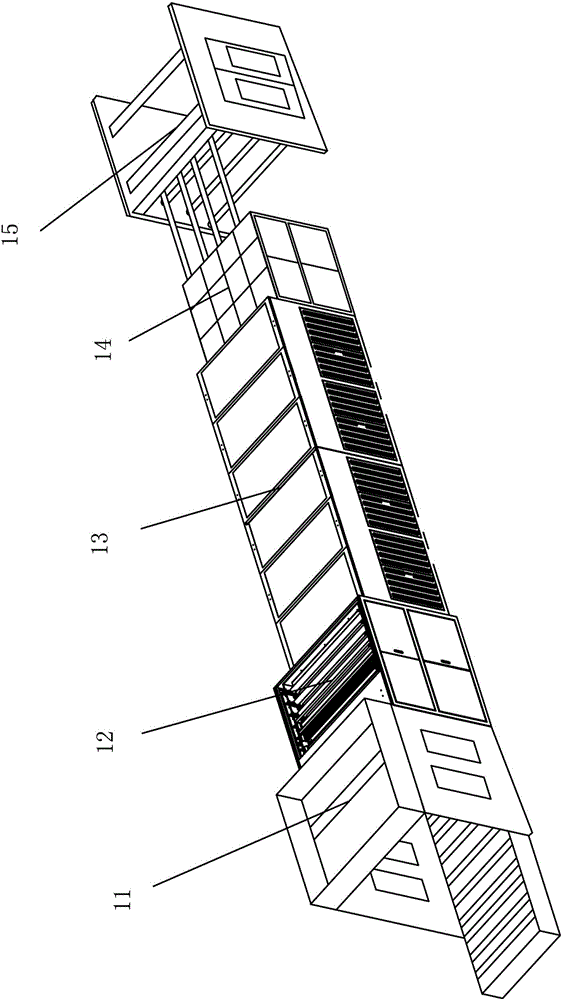

[0018] The plastic plate automatic cleaning production line of the present invention comprises a feed rack 11, a cleaning host 12, a material receiving rack 15, and a hot air drying room 13 and a cooling room 14. After the plastic plate is sent into the cleaning host by the feed rack for cleaning, it is Drying in the hot air drying room, cooling in the cooling room, and unloading from the receiving rack....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com