Novel pneumatic minitype vibrator

A vibrator and micro technology, used in molding machines, foundry molding equipment, metal processing equipment, etc., can solve the problems of difficulty in demoulding sand molds and sand boxes, molding sand not filling the cavity well, and easy molding and sticking to the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

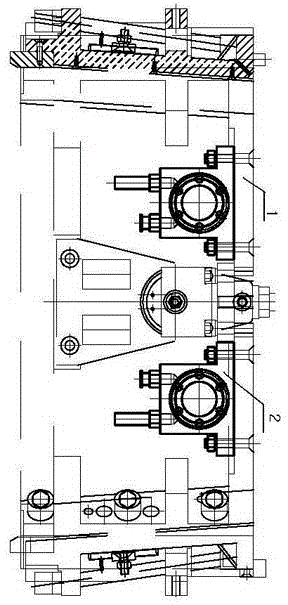

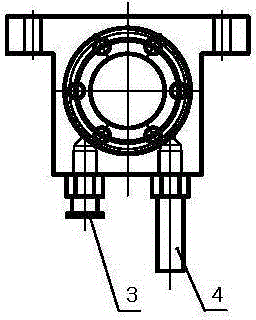

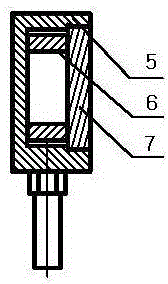

[0015] see Figure 1 to Figure 3 As shown, the present invention includes a lower sand box, a mounting beam 1 and a housing 5, the mounting beam 1 is fixed on the lower sand box, the housing and the mounting beam 1 are fastened together by bolts, and the housing 5 is provided with a cavity inside, a vibrating ring 6 is installed in the cavity, a cover plate 7 is provided on the housing 5 , and a muffler 3 and a pneumatic assembly 4 are provided at the lower part of the housing 5 . The pneumatic assembly 4 is in airtight communication with the cavity. See figure 1 , Two pneumatic miniature vibrators 2 are installed on the lower sand box, and the installation method is installed in a diagonal line, so that the lower sand box can be evenly stressed, and there is no dead angle for vibration and sand falling. See figure 2 and image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com