A laser forming equipment for directional transport of single-particle nano-metal particles

A nano metal particle and laser forming technology, applied in the field of laser sintering forming equipment, can solve the problem that the forming accuracy cannot meet the precision components, and achieve the effect of good market application prospect, positive technical effect, and simple and easy technical means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

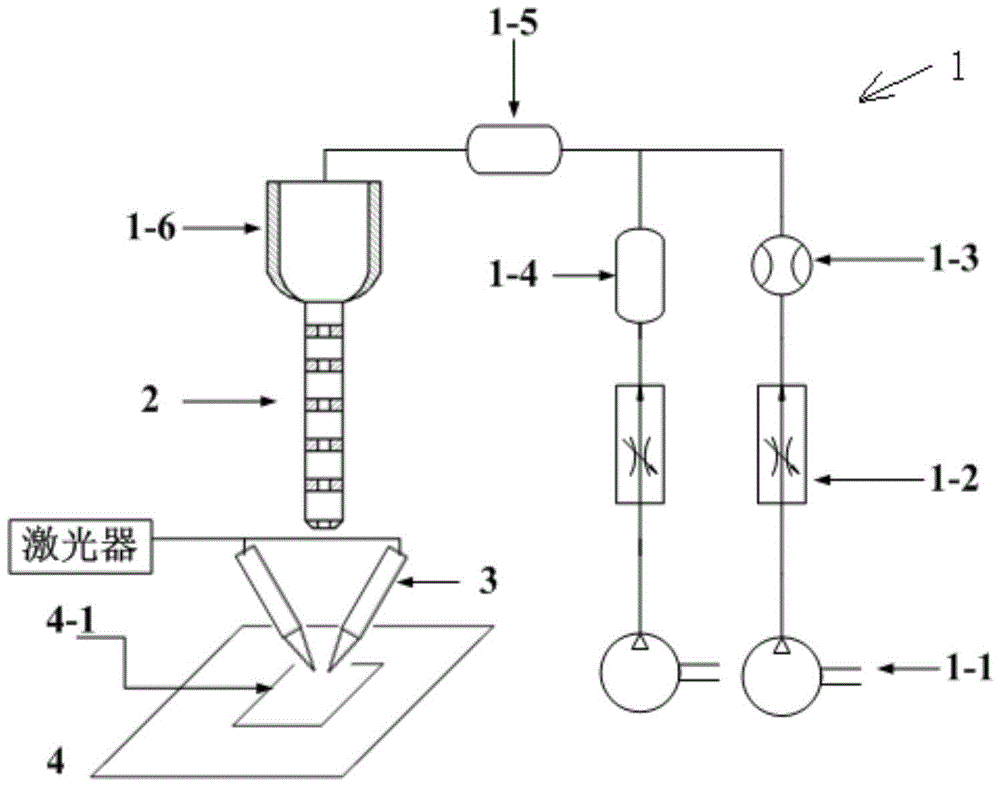

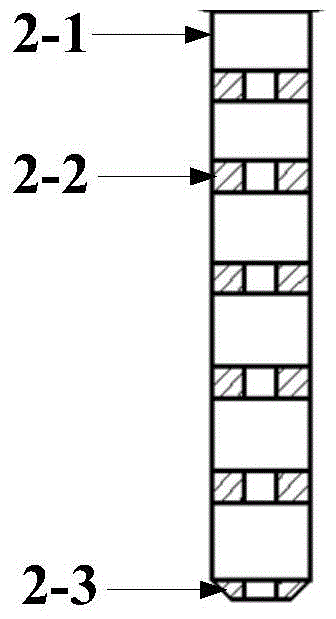

[0029] like figure 1 , 2 shown. The laser molding equipment for directional transport of single-particle nanometer metal particles of the present invention includes a mixed sample feeding system 1, an aerodynamic lens 2, a confocal laser group 3 and a workbench 4;

[0030] The workbench 4 is a movable platform, moving in the direction of X, Y or Z axis, that is, moving on the same horizontal plane of X and Y, can obtain a two-dimensional pattern with nanometer line width; moving in the direction of Z axis, the pattern is gradually Layers are stacked to obtain 3D models with nanoscale precision.

[0031] The mixed sampling system 1 is connected with an aerodynamic lens 2, and the aerodynamic lens 2 is located above a workbench 4; the workbench 4 is used to place a sintered matrix 4-1 to accept nanoparticles.

[0032] The confocal laser group 3 is located between the aerodynamic lens 2 and the table 4 . Each laser in the confocal laser group 3 has a common focal point, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com