Boring beveling machine for end face of flange

A technology of beveling machine and end face, which is applied in the direction of boring/drilling, parts of boring machine/drilling machine, metal processing machinery parts, etc. It can solve the problems of increasing labor costs, troublesome flange manufacturing, and difficulty in achieving symmetry, etc., to achieve The structure is simple, the operation is reasonable, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

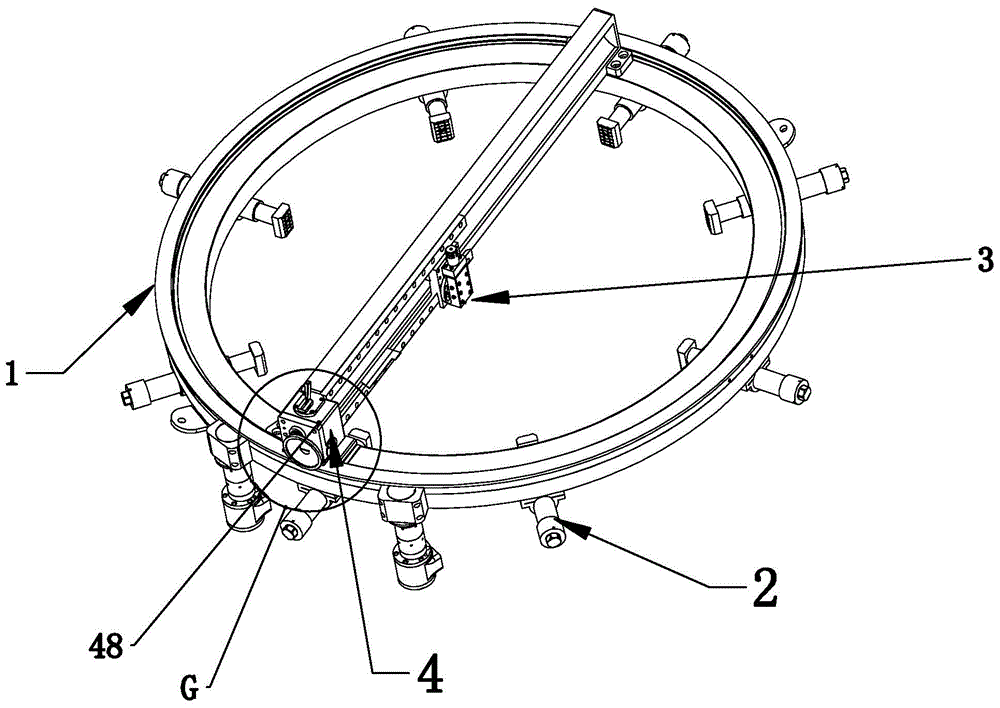

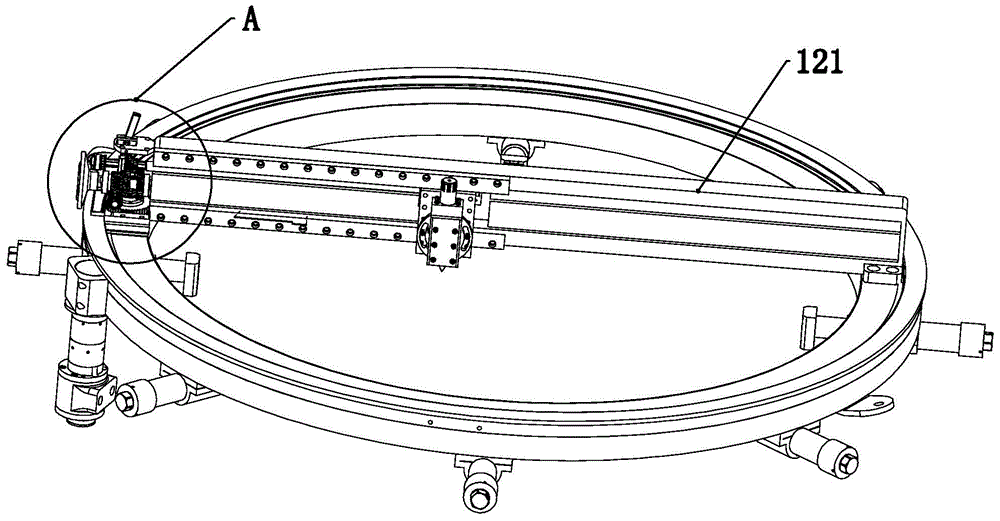

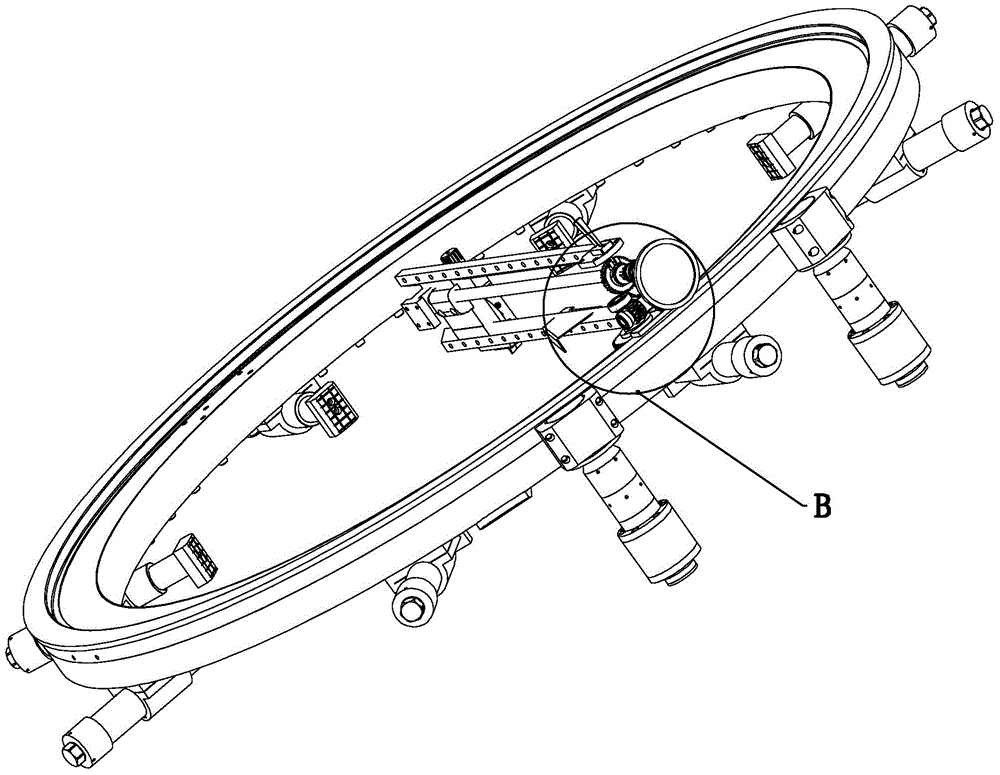

[0033] like figure 1 — Figure 16As shown, a flange end face boring and beveling machine includes a circular turntable seat 1, a clamp arm 2, a tool mounting frame 3 and a drive mechanism 4 for advancing and retreating the knife, wherein the circular turntable seat 1 includes a fixed plate 11, The gear rotating disc 12 and the inner gear disc 13, the fixed disc 11 or the inner gear disc 13 are provided with a transmission device 14, the transmission device 14 here can be electric transmission or hydraulic transmission or pneumatic transmission, the transmission device 14 can be set There are multiple groups, the gear rotating disk 12 is rotatably arranged on the fixed disk 11, the inner toothed disk 13 is fixedly arranged on the fixed disk 11, and the first gear 141 on the output shaft of the transmission device 14 meshes with the gear rotating disk 12 , the transmission device 14 works to drive the gear rotating disk 12 to rotate on the fixed disk 11, the gear rotating disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com