Clamping device for gear hobbing

A clamping device and gear technology, which is applied in the field of gear hobbing processing, can solve the problems of unqualified gear processing, reduced production efficiency, and unstable gear clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

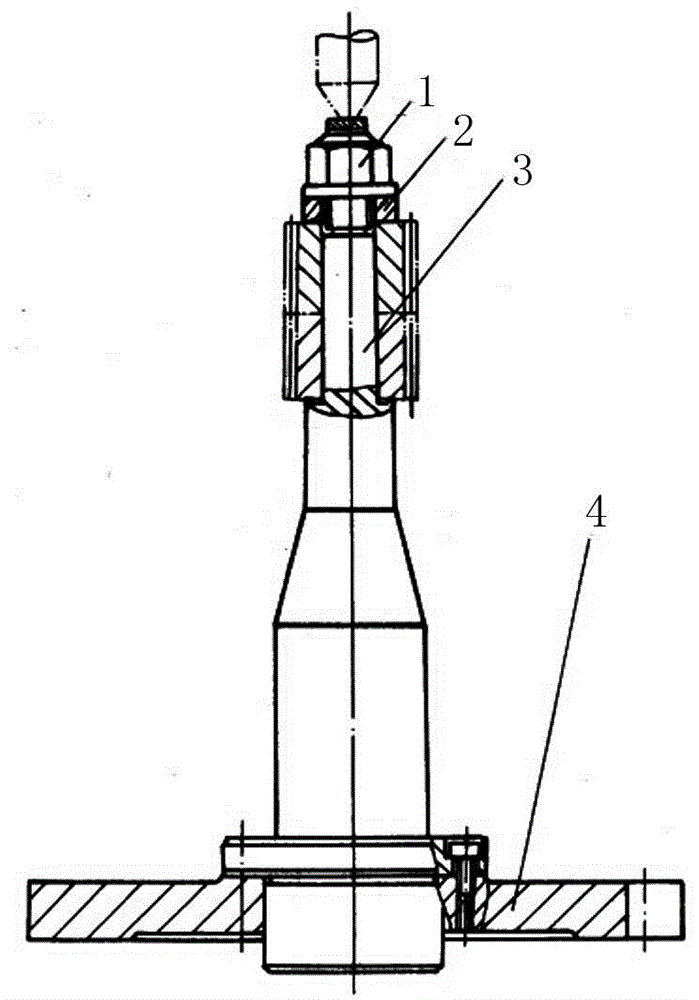

[0013] Embodiment one is basically as attached figure 1 As shown: the clamping device for gear hobbing includes a disc body 4, a mandrel 3, a pressure block 2, a hex nut 1 and a thimble arranged in sequence from bottom to top along the axial direction; the disc body and the machine tool are fixed by bolts , easy to install and disassemble, the disc body is set outside the mandrel, the lower end of the mandrel is provided with a boss against the disc body, the boss can play a role in positioning the mandrel, and the middle part of the upper end of the disc body is provided with a ring bearing the mandrel boss Shaped protrusions, only need to finish the ring-shaped protrusions to ensure the assembly accuracy with the mandrel, without finishing the entire upper end surface of the entire disc body, the edge of the mandrel boss is connected and fixed with the ring-shaped protrusions by screws, Easy to install and disassemble, the boss can transfer the load to the disc body when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com