Engine docking device and docking method

A docking device and engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of interference center of gravity, instability, etc., and achieve the effect of easy operation, accurate docking and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the invention will be further described in conjunction with the accompanying drawings and specific embodiments.

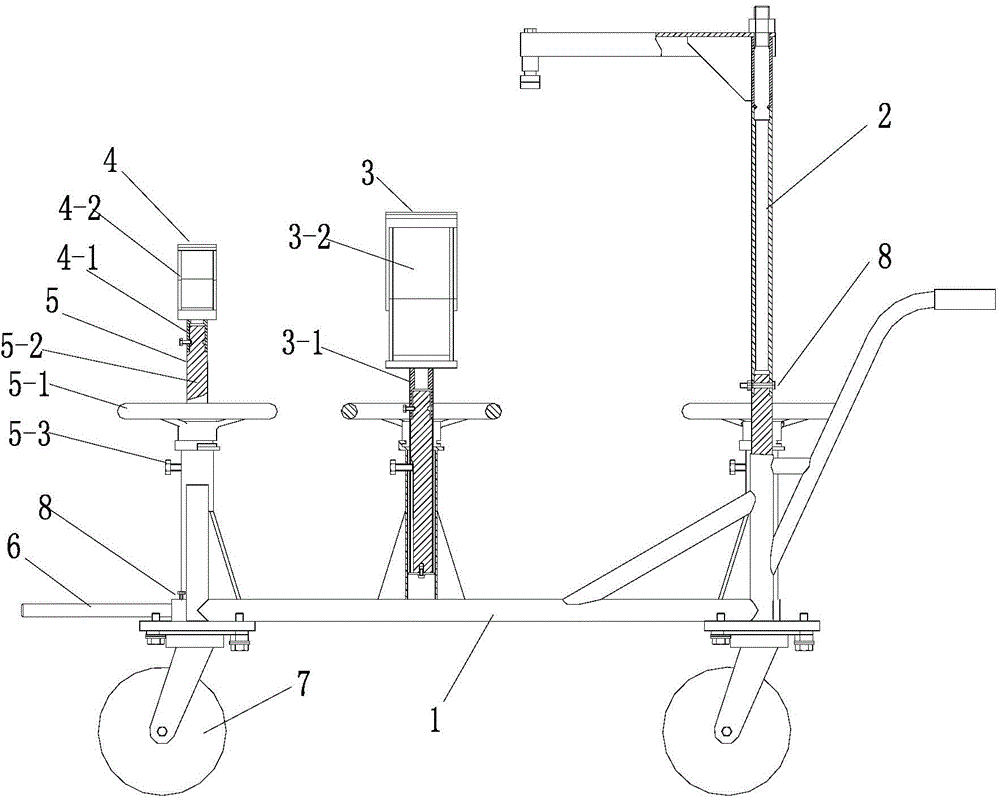

[0037] Such as figure 2 with 3 As shown, an engine docking device mainly includes: a vehicle frame 1, a suspension beam assembly 2, a main support 3, an auxiliary support 4, an adjustment device 5, a mandrel 6, and a wheel 7;

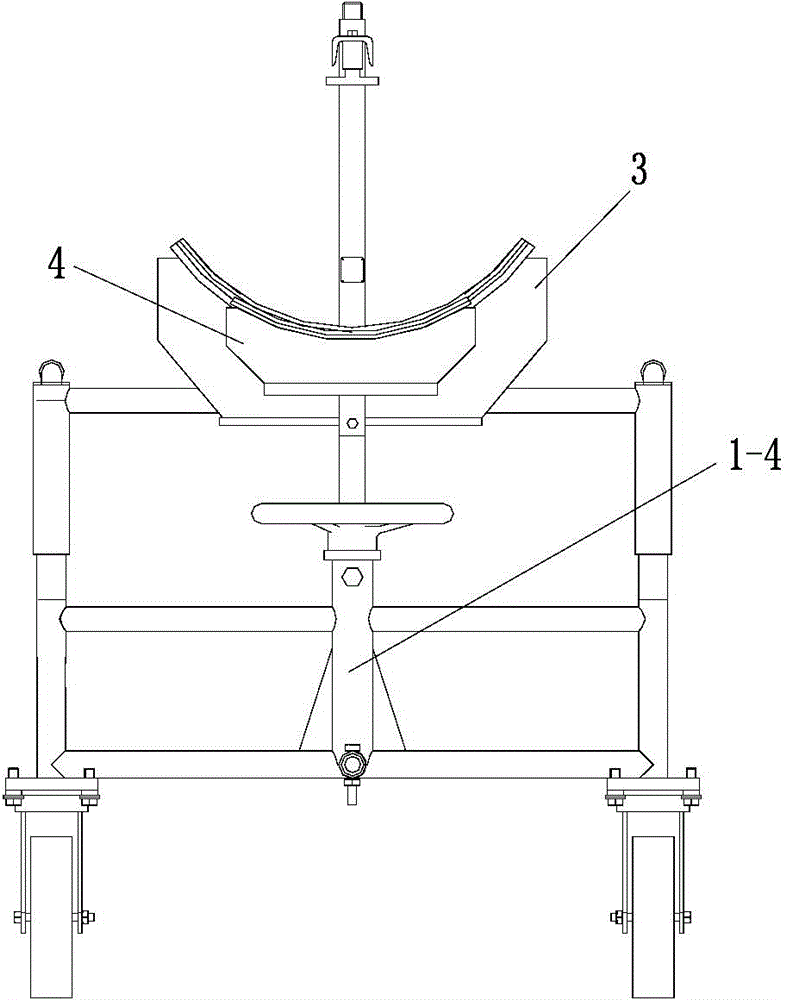

[0038] Such as Figure 4 As shown, the vehicle frame 1 is a weldment, mainly including an underframe 1-1, two handles 1-2, four wheel mounting plates 1-3 and three adjusting device mounting sleeves 1-4;

[0039] Such as Figure 5 with Image 6 As shown, the hanging beam assembly 2 mainly includes a hanging frame 2-1, a beam 2-2, an adapter pipe 2-3, a longitudinal beam 2-4 with a threaded rod at one end, a fastening nut 2-5, two installation Guide pipe 2-6, two connecting pipes 2-7. One end of the crossbeam 2-2 is welded with the transfer pipe 2-3; the threaded rod of the longitudinal beam 2-4 passes through the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com