Fixture for batch installation of bolts of self-balancing electric scooter

A technology for installing fixtures and balancing cars, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing, etc., can solve the problems of inconsistent bolt torque and low installation efficiency, and achieve the effect of consistent bolt torque and high efficiency of bolt installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

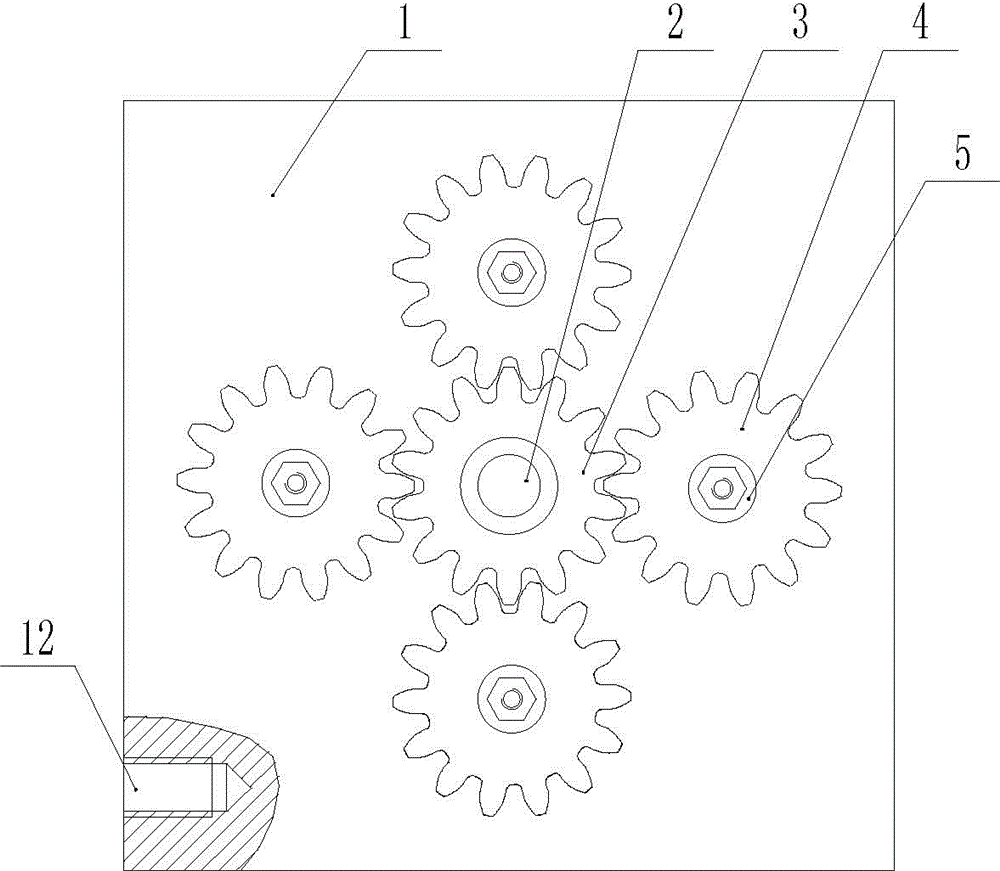

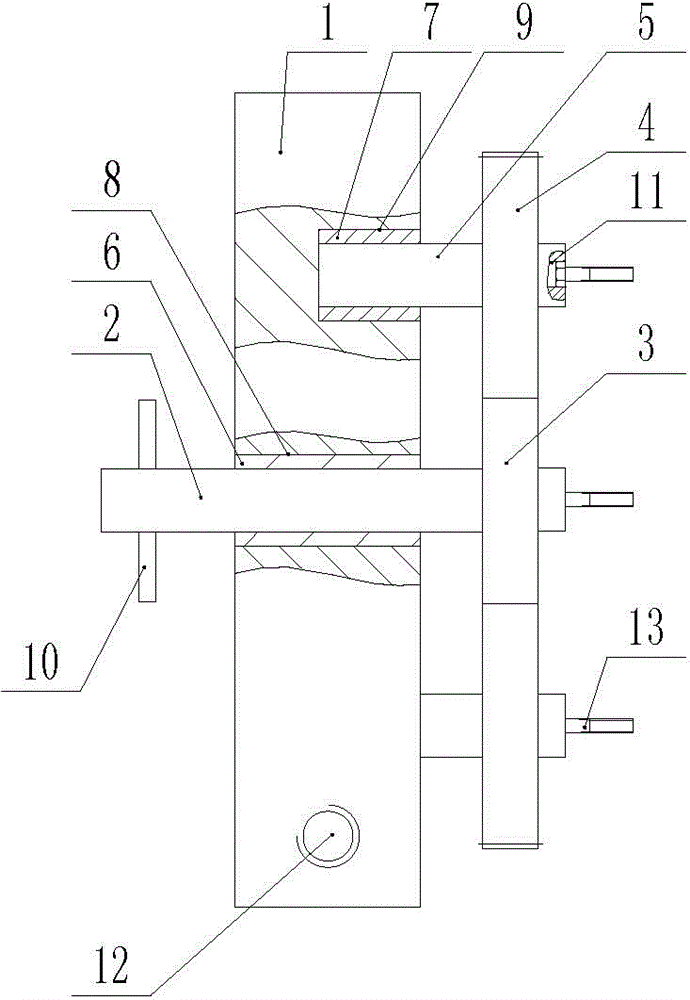

[0017] Such as figure 1 , figure 2 As shown, the balance vehicle bolt batch installation jig of the present invention includes a support base 1 , a rotating shaft 2 , a sun gear 3 , a planetary gear 4 , a driven shaft 5 , a rotating sleeve 6 and a driven sleeve 7 . There is a through hole 8 in the middle of the support seat 1, the inner diameter of the through hole 8 is the same as the outer diameter of the rotating sleeve 6, the inner diameter of the rotating sleeve 6 is slightly larger than the diameter of the rotating shaft 2, and the rotating sleeve 6 is embedded in the through hole 8 Among them, the rotating shaft 2 passes through the rotating sleeve 6, the rotating sleeve 6 and the through hole 8 are interference fit, the rotating shaft 2 and the rotating sleeve 6 are clearance fit, the left end of the rotating shaft 2 is provided with a handle 10, and the sun gear 3 Sleeved on the right end of the rotating shaft 2, the sun gear 3 is fixedly connected with the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com