T-shaped hollowed-out working table for PCB pin loader

A workbench and workbench technology, applied to workbenches, manufacturing tools, etc., can solve the problems of large friction area, large contact area, and aggravated PCB surface wear, so as to reduce friction area, reduce contact area, and reduce defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

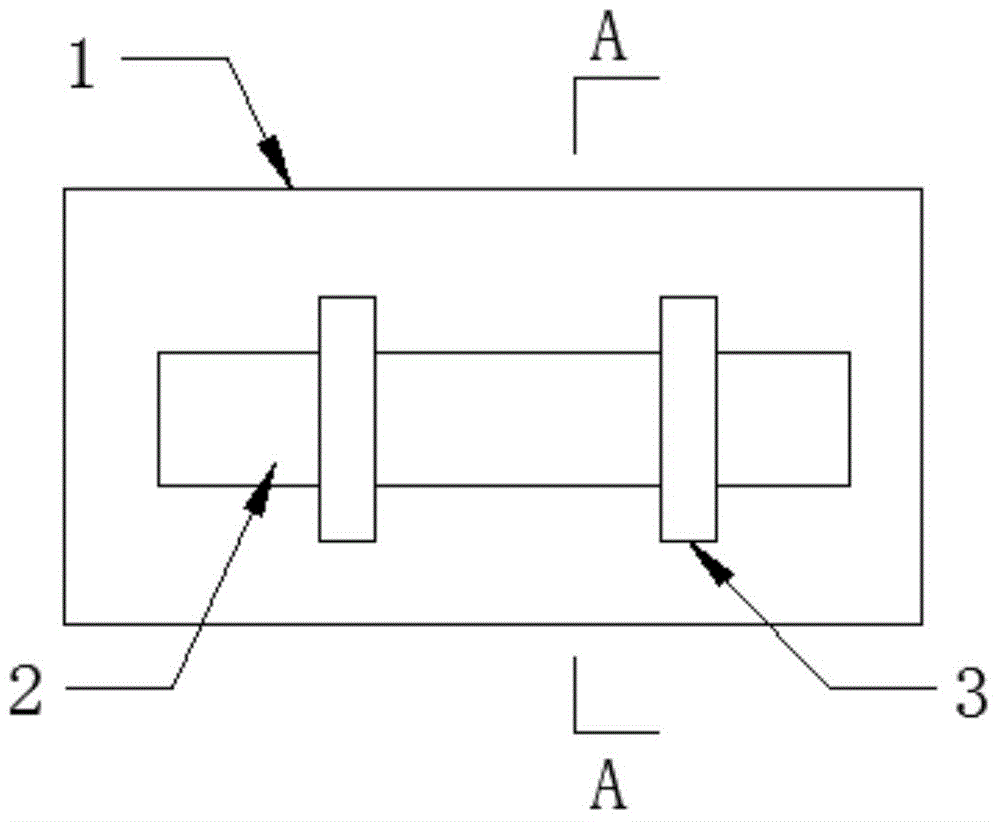

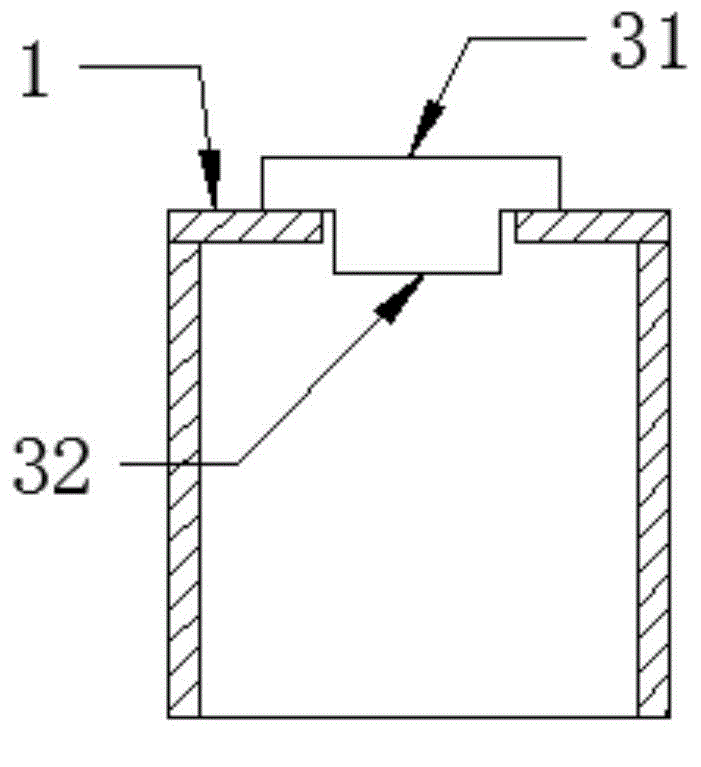

[0015] Embodiment: a T-shaped hollow workbench for a PCB upper pin machine, the upper pin machine has a workbench, the workbench has a worktable surface 1, and a left-right groove 2 is arranged on the described worktable surface, so Two T-shaped support plates 3 are placed in the groove, and the T-shaped support plate is composed of an upper support plate 31 and a plug-in plate 32 extending downward from the middle of the lower surface of the upper support plate. The plate is inserted into the groove through its plug board and its upper support plate is located above the groove, the upper surface of the upper support plate of the T-shaped support plate is parallel to the work surface and forms a gap between the work surface and the work surface. A certain longitudinal distance, the PCB is placed on the upper surface of the upper support plate of the T-shaped support plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com