Composite planet gear set type hybrid power system of birotor motor

A hybrid power system and dual-rotor motor technology, which is applied in the field of power systems, can solve the problems of reduced system reliability, increased system cost, and difficult control, and achieves the effects of reducing requirements, simple structure, and improving system efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

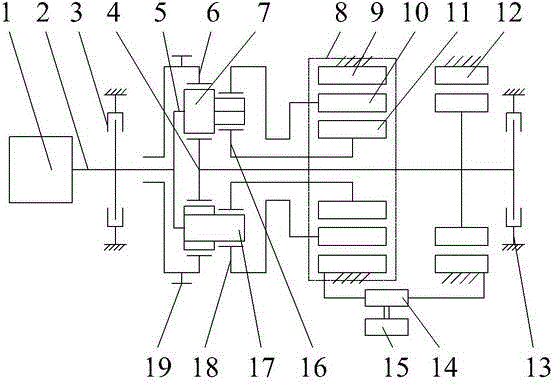

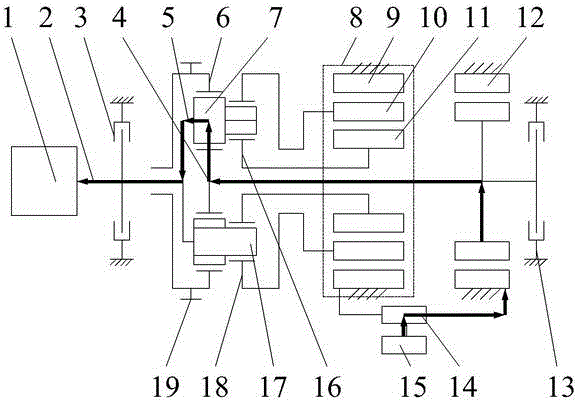

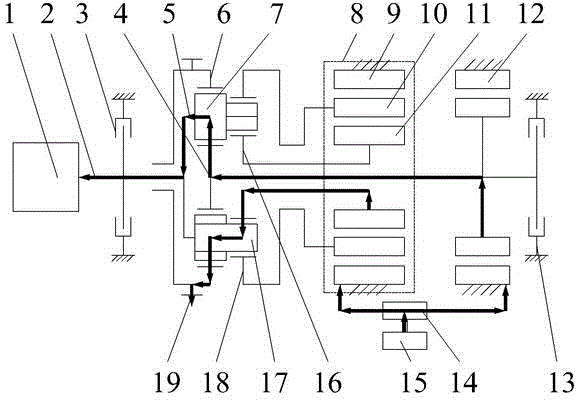

[0018] see figure 1 Shown, be the embodiment of the present invention, this embodiment is made up of engine 1, motor No. 12, motor No. 14. Composed of a supercapacitor 15 and an output gear 19, the No. 2 motor 8 is a double-rotor motor composed of an inner rotor 11, an outer rotor 10 and a stator 9; the composite double planetary row includes a front planetary row and a rear planetary row, Wherein the front planetary row comprises the front row sun gear 4, the front row planetary gear 7, the front row ring gear 6 and the shared planet carrier 5 of the front row and the rear planetary row, and the rear planetary row includes the rear row sun gear 16, the rear row planetary gear 17, The planetary carrier 5 shared by the rear ring gear 18 and the front and rear planetary rows; the engine 1 is connected with the planetary carrier 5 through the input shaft 2; the No. 1 motor 12 is connected with the front row sun gear 4; the No. 2 motor The inner rotor 11 of 8 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com