Motor-integrated electric control brake master cylinder driving system

An electronically controlled braking and motor-integrated technology, applied in brake transmissions, brakes, vehicle components, etc., can solve problems such as poor pedal feel, poor active safety function, and large booster volume, to ensure safe and reliable operation, universal Strong performance and good pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

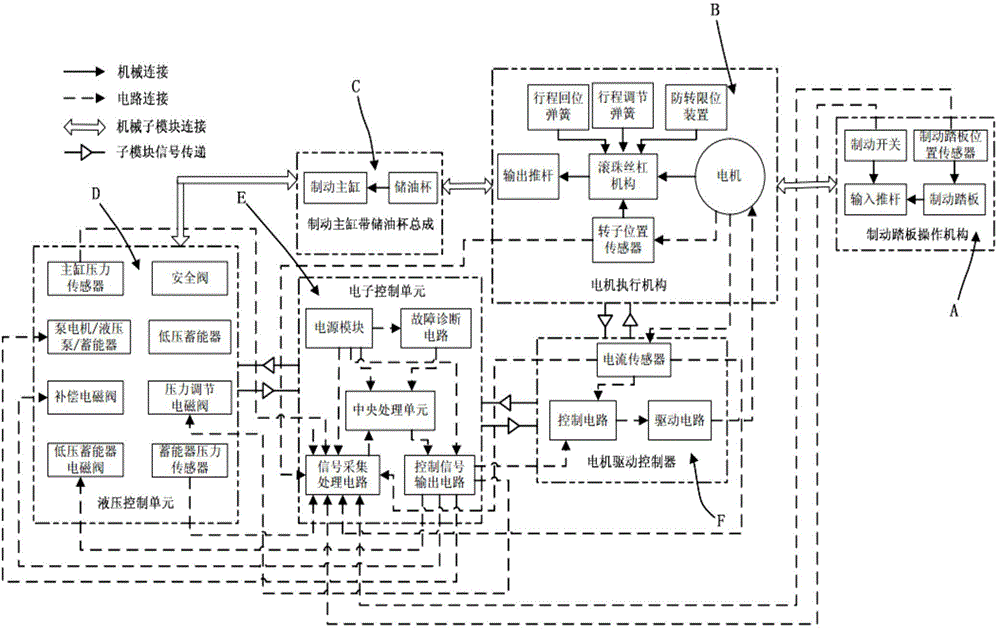

[0036] refer to figure 1 , the integrated motor electronic control brake master cylinder drive system of the present invention includes a brake pedal operating mechanism A, a motor actuator B, a brake master cylinder assembly C, a hydraulic control unit D, an electronic control unit E and a motor drive controller F.

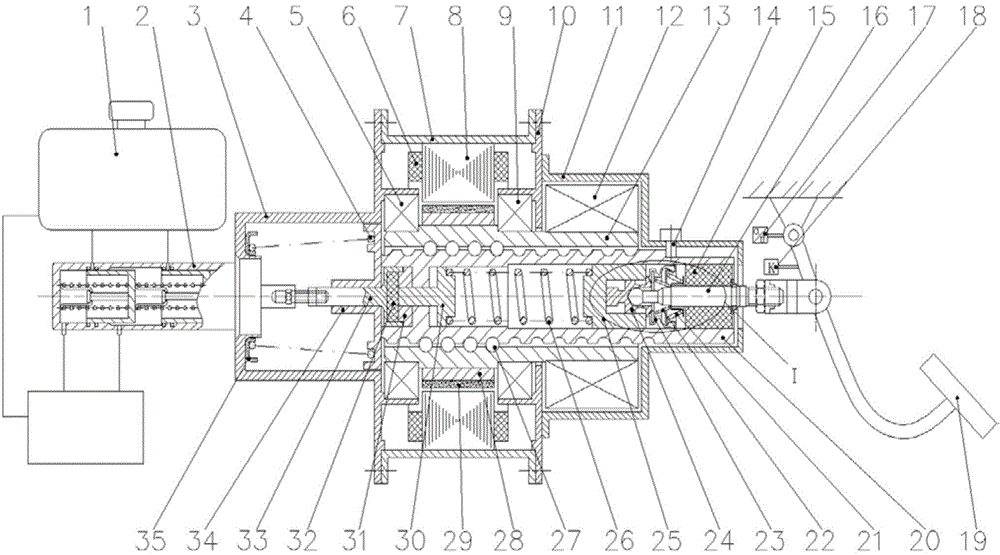

[0037] The brake pedal operating mechanism A is mainly composed of an input push rod 16 , a brake pedal position sensor 17 , a brake switch 18 and a brake pedal 19 .

[0038] The upper end of the brake pedal 19 has a section of groove and the right end of the input push rod 16 is connected by bolts, and the brake pedal angular position sensor 17 is connected with the topmost rotating shaft of the brake pedal 19 by bolts, so that the rotating part of the brake pedal angular position sensor 17 Rotate together with the brake pedal shaft; brake switch 18 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com