Bag manufacturing filling and sealing machine

A filling and sealing machine and bag-making technology, which is applied in the directions of packaging sealing/fastening, packaging item types, special packaging items, etc., can solve the problem of unsuitable production of non-terminal sterilized preparations in large-capacity bags, low reliability, and complex structure And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The core of the present invention is to provide a bag making and filling sealing machine capable of producing large-capacity bags of non-terminal sterilized preparation products.

[0085] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

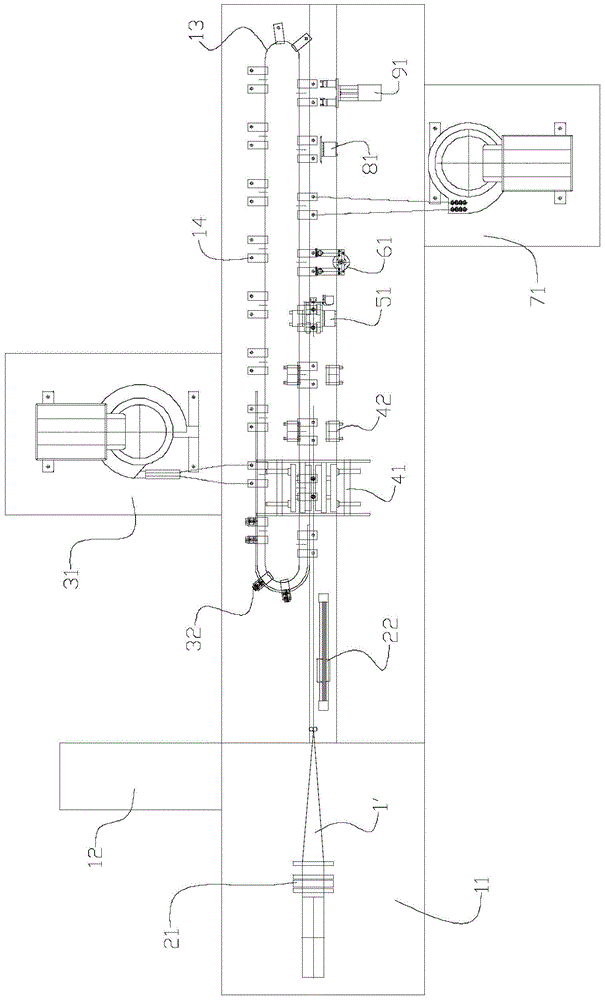

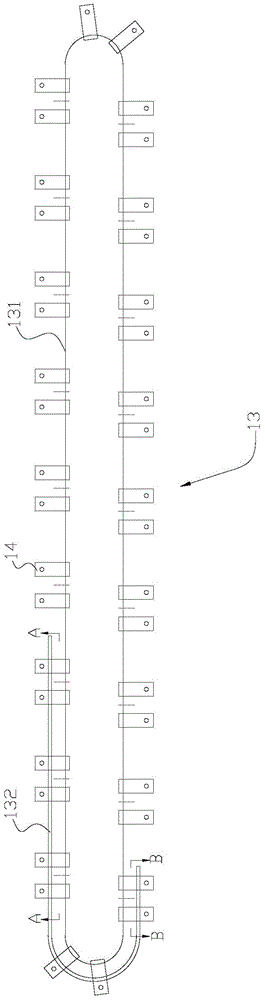

[0086] figure 1 It is a structural schematic diagram of a specific embodiment of the bag making and filling machine provided by the present invention.

[0087] In this embodiment, the bag making and filling machine includes a frame 11 , a power distribution cabinet 12 and an endless conveying assembly 13 installed on the frame 11 .

[0088] The frame 11 is provided with various mechanisms for producing large-capacity bagged non-terminal sterilized preparation products, specifically including a film material supply mechanism, a delivery port mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com