Automatic control method for 10-kv switch cabinet and transfer trolley

An automatic control and transfer vehicle technology, which is applied in the conveyor control device, transportation and packaging, conveyors, etc., can solve the problem that the transfer vehicle can not be automatically pushed and pulled in place and automatically pulled out of the switch car, etc., to improve safety and reliability, The effect of reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

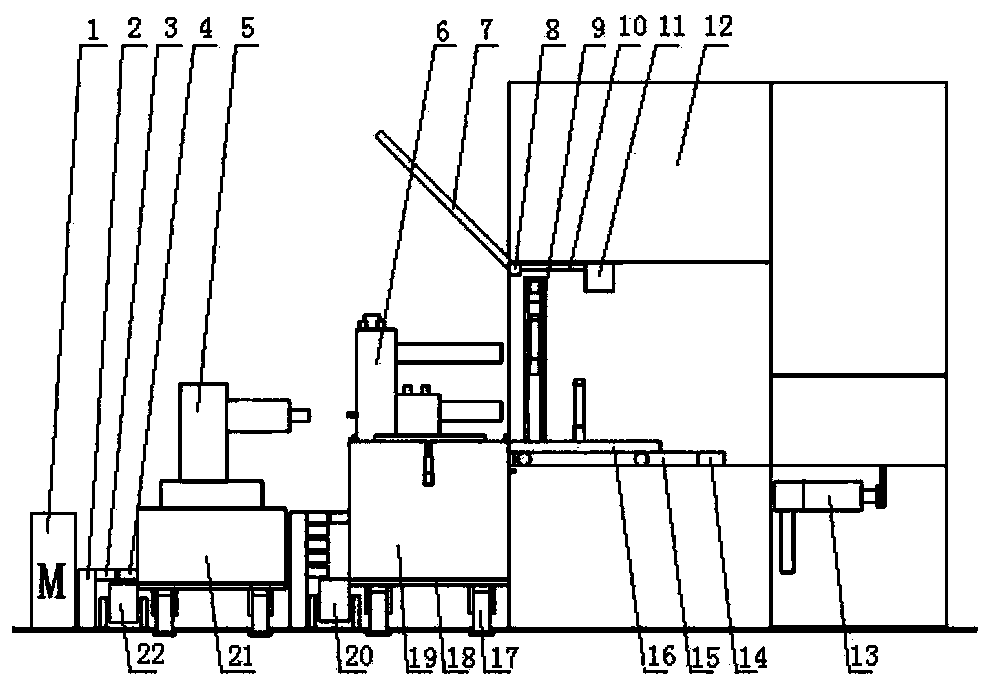

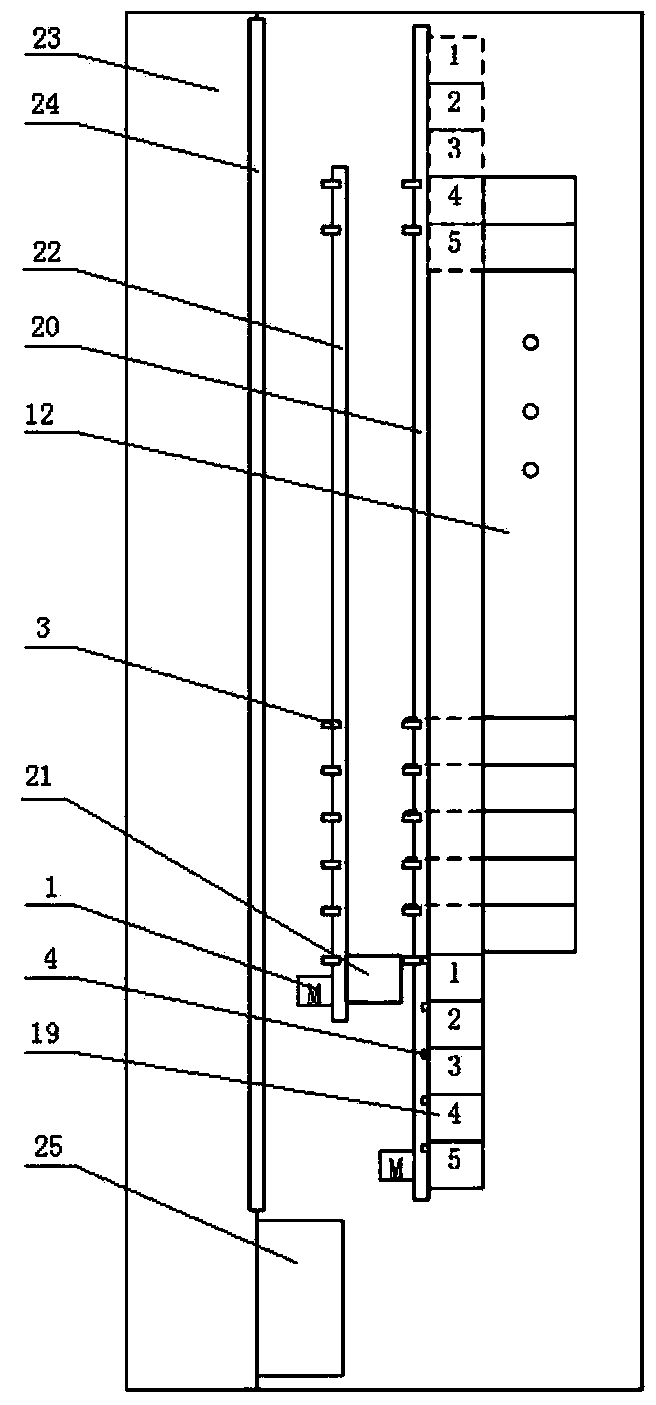

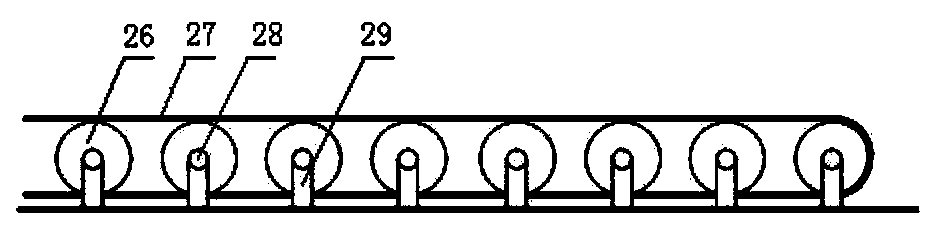

[0051] An automatic control system for a 10kv switch cabinet and a transfer vehicle, comprising a switch cabinet 12, a switch trolley 6, a clamping device 9 for the switch trolley, a transfer trolley 19, a transfer trolley conveyor belt 20, a mechanical arm 5, a mechanical arm platform trolley 21, a mechanical Arm platform trolley conveyor belt 22, positioning rod 2, and proximity switch 3, install the switch trolley in the switch cabinet through the clamping device of the switch trolley, and install the transfer car conveyor belt in parallel at a certain distance from the switch cabinet door 7 side of the switch cabinet , multiple transfer vehicles are slidably installed on the transfer vehicle conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com