Clean type belt material separation unit and material separation method thereof

A cleaning and belt technology, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of poor material distribution efficiency, low degree of automation, inability to achieve clean production, etc., and achieve good cleaning effect and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

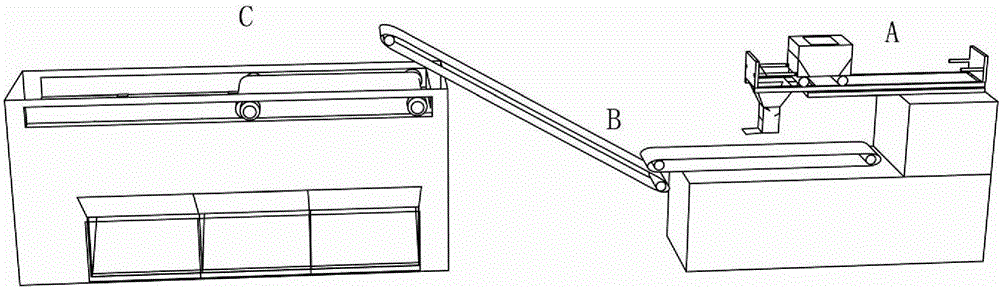

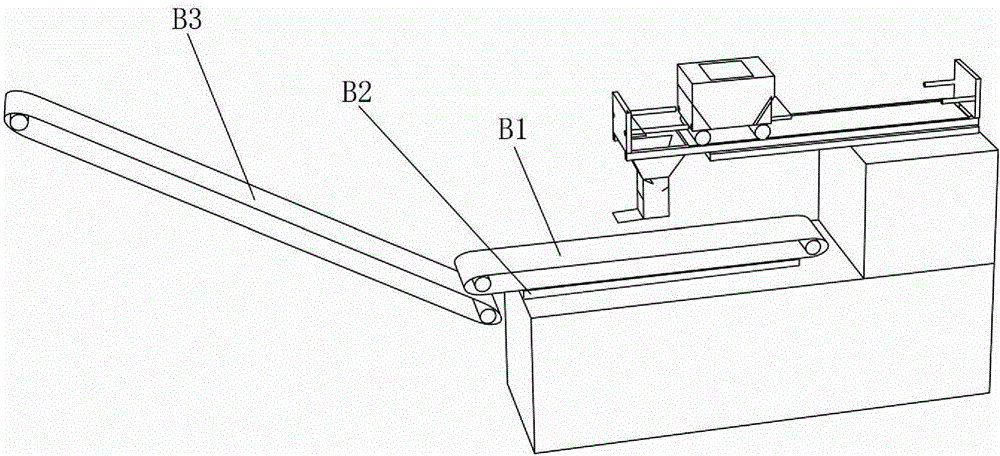

[0038] Such as figure 1 As shown, the clean belt distributing unit includes an unloading mechanism A, a feeding mechanism B and a material collecting mechanism C.

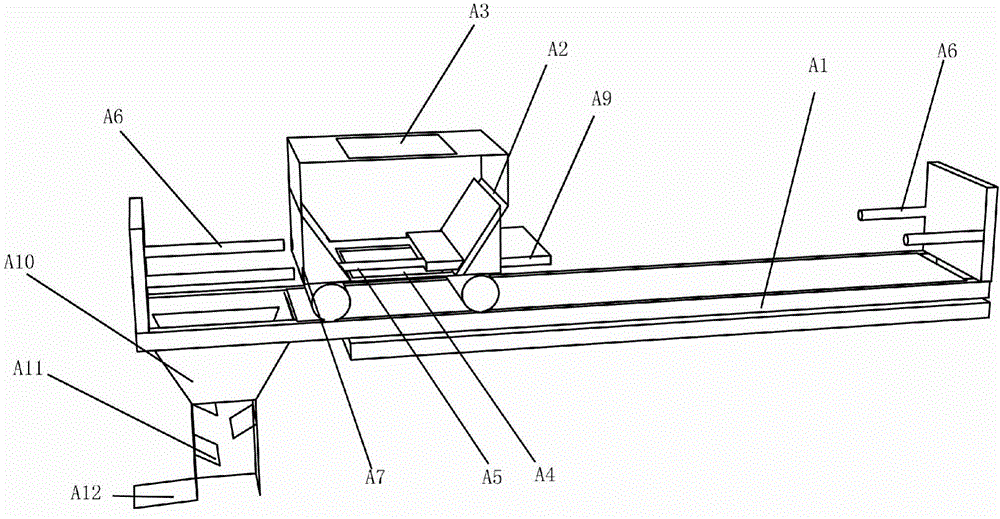

[0039] Such as figure 2 Shown is the unloading mechanism A, the unloading platform is provided with an unloading trolley A2, and the left end of the unloading platform A1 is provided with a discharge bin A10. The upper part and the bottom of the unloading trolley A1 are respectively provided with an inlet A3 and an outlet A4, and the outlet A4 is provided with a discharge baffle A9, and the discharge baffle A9 can slide in the tank at the bottom of the unloading trolley A2 , one end of which is connected to the telescopic rod A5, and one end of the telescopic rod A5 is connected to the bottom of the unloading trolley A2, and the two sides of the unloading platform A1 are provided with triggering discharge baffles A9, so that the discharge baffles A9 control the discharge port A4 To open or close the trigger leve...

Embodiment 2

[0052] In this embodiment, the difference from Embodiment 1 is that the conveyor belt can be replaced with other conveying elements, such as a conveying grid, a conveying net, etc., and the rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com