Preparation process of high-wear-resistance soft rubber and plastic ejection foam material

A production process, high wear-resistant technology, applied in applications, clothing, footwear, etc., can solve the problems of high hardness of foam materials, achieve good softness, improve plastic texture, and improve wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

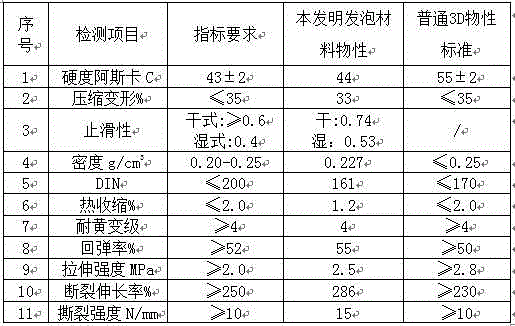

Image

Examples

Embodiment approach 1

[0025] The manufacturing process of soft and high wear-resistant rubber-plastic injection foaming material includes the following steps in sequence:

[0026] a. Preparation: prepare raw materials in parts by weight, including 46.5 parts of ethylene-vinyl acetate copolymer with VA content of 26%, 22 parts of ethylene-vinyl acetate copolymer with VA content of 40%, and 14 parts of ethylene-octene copolymer , 14 parts of terpolymer of ethylene-propylene and non-conjugated diene, 13 parts of isoprene and styrene block polymer, 12 parts of vinyl trimethoxysilane and resin copolymer, diisoprene peroxide Propylene benzene 0.9 parts, azodicarbonamide 2.2 parts, hydrated magnesium silicate ultrafine powder 7 parts, zinc oxide 1.6 parts, octadecanoic acid 0.55 parts, free acid and zinc oxide copolymer 0.9 parts, active agent and silicon 0.25 parts of acid salt copolymer;

[0027] b. Mixing: Pour the prepared raw materials into an internal mixer for mixing. When the temperature reaches 99°C,...

Embodiment approach 2

[0033] The manufacturing process of soft and high wear-resistant rubber-plastic injection foaming material includes the following steps in sequence:

[0034] a. Preparation: prepare raw materials in parts by weight, including 45 parts of ethylene-vinyl acetate copolymer with 22% VA content, 24 parts of ethylene-vinyl acetate copolymer with 38% VA content, and 10 parts ethylene-octene copolymer , 15 parts of ethylene-propylene and non-conjugated diene terpolymer, 15 parts of isoprene and styrene block polymer, 10 parts of vinyl trimethoxysilane and resin copolymer, diisoperoxide 1.0 part of propylbenzene, 2.1 part of azodicarbonamide, 5 parts of hydrated magnesium silicate ultrafine powder, 1.8 parts of zinc oxide, 0.6 part of octadecanoic acid, 1.0 part of free acid and zinc oxide copolymer, active agent and silicon 0.3 parts of acid salt copolymer;

[0035] b. Mixing: Pour the prepared raw materials into an internal mixer for mixing. When the temperature reaches 95°C, the first t...

Embodiment approach 3

[0039] The manufacturing process of soft and high wear-resistant rubber-plastic injection foaming material includes the following steps in sequence:

[0040] a. Preparation: prepare raw materials in parts by weight, including 48 parts of ethylene-vinyl acetate copolymer with 28% VA content, 20 parts of ethylene-vinyl acetate copolymer with 36% VA content, and 15 parts of ethylene-octene copolymer , 13 parts of ethylene-propylene and non-conjugated diene terpolymer, 12 parts of isoprene and styrene block polymer, 13 parts of vinyl trimethoxysilane and resin copolymer, diisoprene peroxide 0.8 parts of propylbenzene, 2.1 parts of azodicarbonamide, 8 parts of hydrated magnesium silicate ultrafine powder, 1.5 parts of zinc oxide, 0.5 parts of octadecanoic acid, 0.8 parts of free acid and zinc oxide copolymer, active agent and silicon 0.2 parts of acid salt copolymer;

[0041] b. Mixing: Pour the prepared raw materials into the internal mixer for mixing. When the temperature reaches 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap