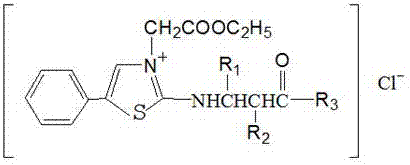

A kind of anti-corrosion and anti-wear anti-corrosion lubricant of high-concentration acid solution and preparation method thereof

A high-concentration, lubricant technology, applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve problems such as high cost, poor acid corrosion resistance, and environmental pollution, and achieve the effect of strong electron transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

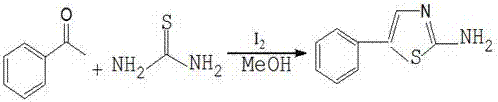

[0034] The first step: 2-amino-5-phenylthiazole synthesis:

[0035] In a three-necked flask equipped with a thermometer, a stirrer and a spherical condenser, the molar ratio is n 硫脲 :n 酮 :n 碘 =1~1.5:1~1.2:1, add 5.7147g of thiourea, 5.2ml of acetophenone, 12.6359g of elemental iodine, then add 25ml of methanol to dissolve the raw materials, raise the temperature to 60~80°C and heat to reflux for 4h, while hot The reaction solution was poured into 20ml of hot water, stirred at constant temperature for 15 minutes, then suction filtered while it was hot to remove impurities generated in the reaction, the filtrate was extracted three times with anhydrous ether, and the aqueous layers were combined; then an appropriate amount of saturated sodium hydroxide solution was added thereto, Adjust its pH value to about 8, cool the solution to room temperature, a large number of light yellow solids precipitate, and obtain the crude product by suction filtration; the crude product is recry...

Embodiment 2

[0039] The first step: 2-amino-5-phenylthiazole synthesis:

[0040] In a three-necked flask equipped with a thermometer, a stirrer and a spherical condenser, the molar ratio is n 硫脲 :n 酮 :n 碘=1~1.5:1~1.2:1 ratio, add 5.7525g of thiourea, 5.2ml of acetophenone, 12.6417g of elemental iodine, then add 25ml of isopropanol to dissolve the raw materials, raise the temperature to 60~80°C and heat to reflux for 4h. Pour the reaction solution into 20ml of hot water, stir at constant temperature for 15 minutes, then filter while it is hot to remove impurities generated in the reaction, extract the filtrate three times with anhydrous ether, combine the water layer; then add an appropriate amount of saturated sodium hydroxide to it Solution, adjust its pH value to about 8, cool the solution to room temperature, a large amount of light yellow solid precipitates, and obtain the crude product by suction filtration; the crude product is recrystallized with absolute ethanol, the product is l...

Embodiment 3

[0044] The first step: 2-amino-5-phenylthiazole synthesis:

[0045] In a three-necked flask equipped with a thermometer, a stirrer and a spherical condenser, the molar ratio is n 硫脲 :n 酮 :n 碘 =1~1.5:1~1.2:1 ratio, add 5.7091g of thiourea, 5.2ml of acetophenone, 12.6544g of elemental iodine, then add 25ml of methanol to dissolve the raw materials, heat up to 60~80℃ and heat to reflux for 4h. The reaction solution was poured into 20ml of hot water, stirred at constant temperature for 15 minutes, then suction filtered while it was hot to remove impurities generated in the reaction, the filtrate was extracted three times with anhydrous ether, and the aqueous layers were combined; then an appropriate amount of saturated sodium hydroxide solution was added thereto, Adjust its pH value to about 8, cool the solution to room temperature, a large number of light yellow solids precipitate, and obtain the crude product by suction filtration; the crude product is recrystallized with abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com