A method for recovering and utilizing potential energy of an excavator arm and its control device

A potential energy recovery and control device technology, which is applied to fluid pressure actuators, mechanically driven excavators/dredgers, mechanical equipment, etc., can solve problems such as difficulty, pressure cannot be released, and service life of hydraulic components is reduced, achieving manufacturing And the effect of convenient layout and installation, reducing heat generation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

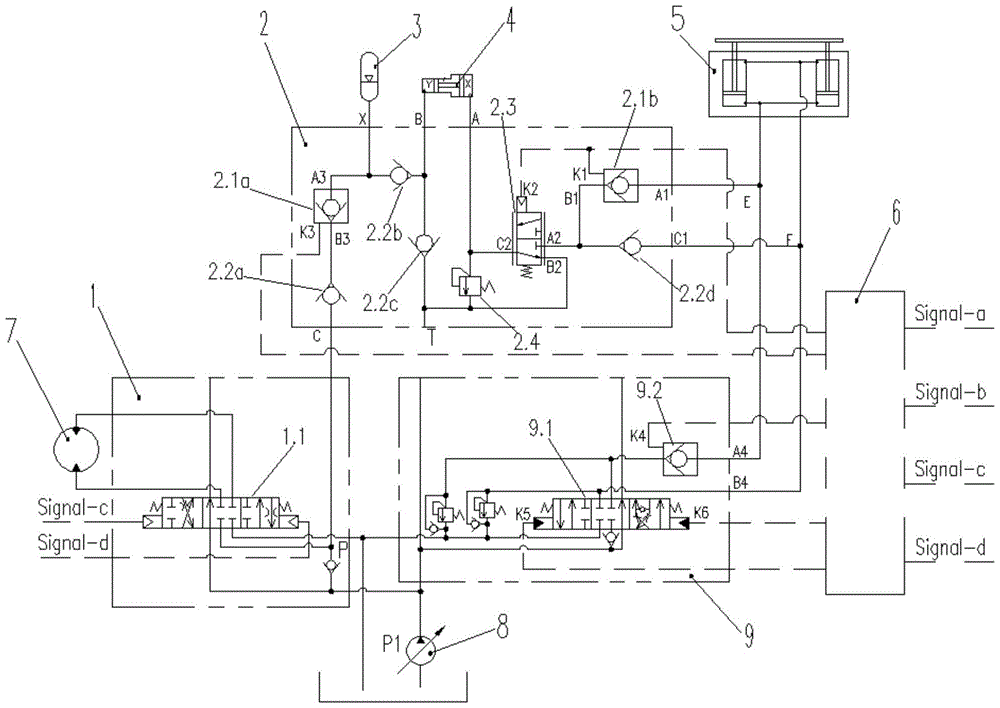

[0024] Below will combine concrete embodiment and appended figure 1 The present invention is described in further detail:

[0025]The method of recovering and utilizing the potential energy of the excavator arm, when the boom is lowered, the first stage of boosting is realized through control according to the area difference between the rodless cavity and the rod cavity of the boom cylinder, and then the second stage of boosting is realized by the booster cylinder , through the two-stage pressurization, the potential energy of the boom lowering is converted into high-pressure energy and stored in the accumulator; when the energy is released, the high-pressure oil stored in the accumulator is introduced into the oil inlet of the swing control valve by controlling, Then, the pressure oil in the accumulator is introduced into the swing motor through the swing control valve to drive the swing operation.

[0026] Preferably, the first stage of supercharging in the two-stage superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com