Reversed loader lap joint middle trough with guide mechanisms

A technology of a guiding mechanism and a loader, which is used in earth-moving drilling, transportation and packaging, underground transportation, etc., can solve problems such as the inability of trucks to pass on the track and the inability to install belt conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

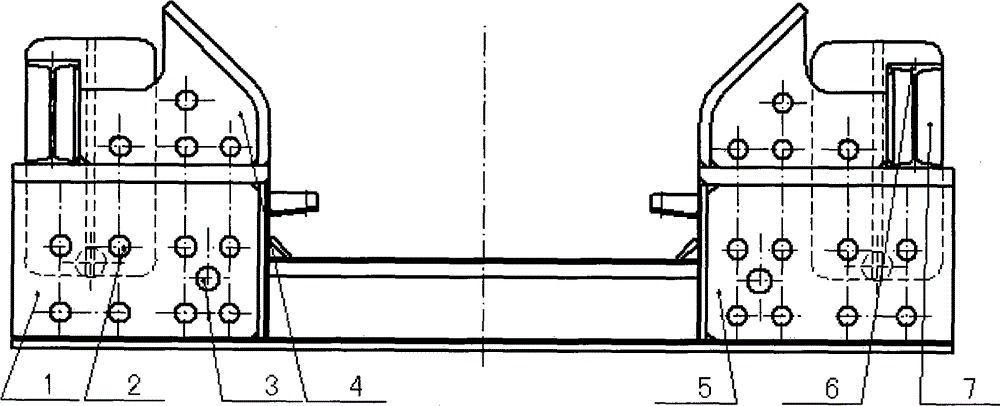

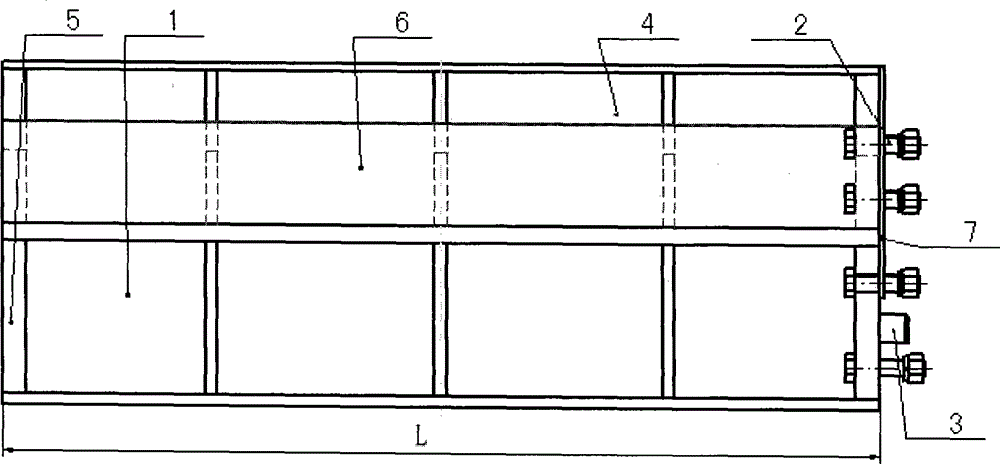

[0015] A guide mechanism 6 is set above both sides of the widened tank body 1. This example is a welded guide rail (I-beam 180×94×6.5) assembly, and a limit device 7 limit plate is provided at both ends of the guide mechanism 6, and a baffle is used. 4 V-shaped bent plate structure, the two ends of the trough body 1 are provided with pins, pin holes, and connecting plates 5 through holes for bolts, which can be rigidly connected with the unloading trough and the connecting trough through the positioning of the pin 3 and the connection of the bolt 2. The guiding mechanism above both sides of the body 1 is overlapped with the traveling part of the reloading machine to realize the guiding function; the traveling part of the reloading machine is a walking trolley in this example.

[0016] Specific operation process:

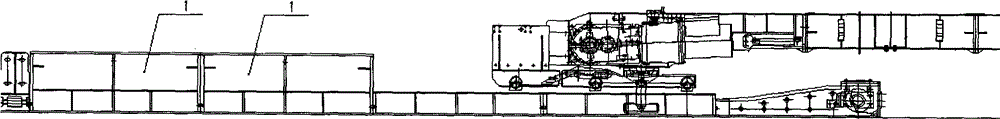

[0017] When there is a guide mechanism for trucks to pass through or other non-detachable obstacles in the transportation lane, two loaders can be used to overlap. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com