Nitrogen spring restored cylinder with pantograph two-stage pistons

A nitrogen gas spring, pantograph technology, applied in the direction of collectors, electric vehicles, power collectors, etc., can solve the problems of insecurity, instability, large preload force, etc., to achieve convenient loading and unloading, small installation space, reset smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] The preferred embodiment of the pantograph secondary piston nitrogen spring reset cylinder of the present invention is:

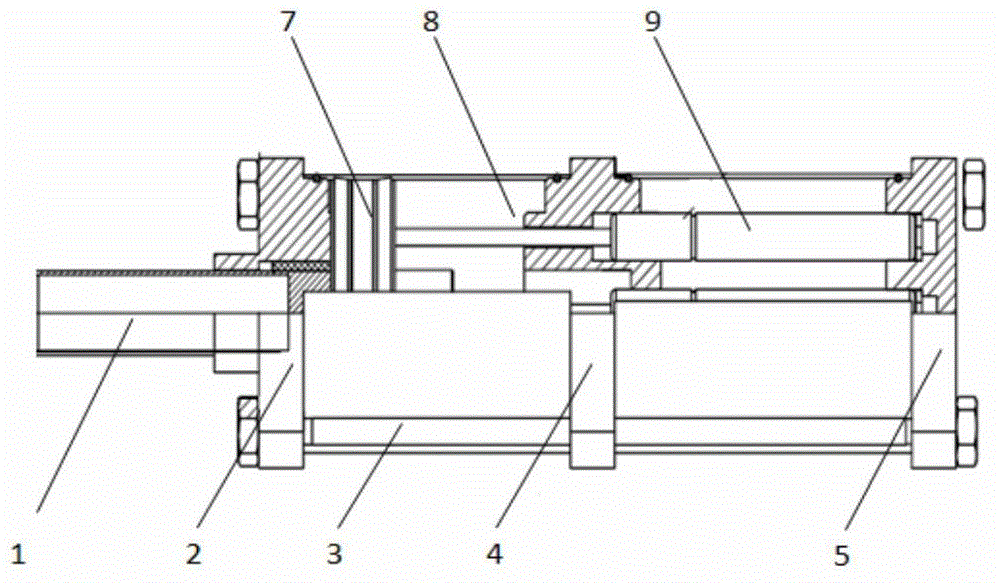

[0017] It includes a cylinder body, a front end cover and a rear end cover, a first-stage piston is arranged in the cylinder body, four nitrogen gas springs are arranged in the cylinder body, the rear end of the nitrogen gas spring is fixedly connected with the rear end cover, and the The front end of the nitrogen gas spring is connected to the first-stage piston, and the first-stage piston is provided with a second-stage piston.

[0018] The rear end of the second-stage piston is provided with a spherical structure, and the first-stage piston is provided with a conical washer matched with the spherical structure.

[0019] A transition end cover is provided between the front end cover and the rear end cover, each end cover is connected by a tie rod, the rear part of the nitrogen gas spring is fixed on the transition end cover and the rear end cover, ...

specific Embodiment

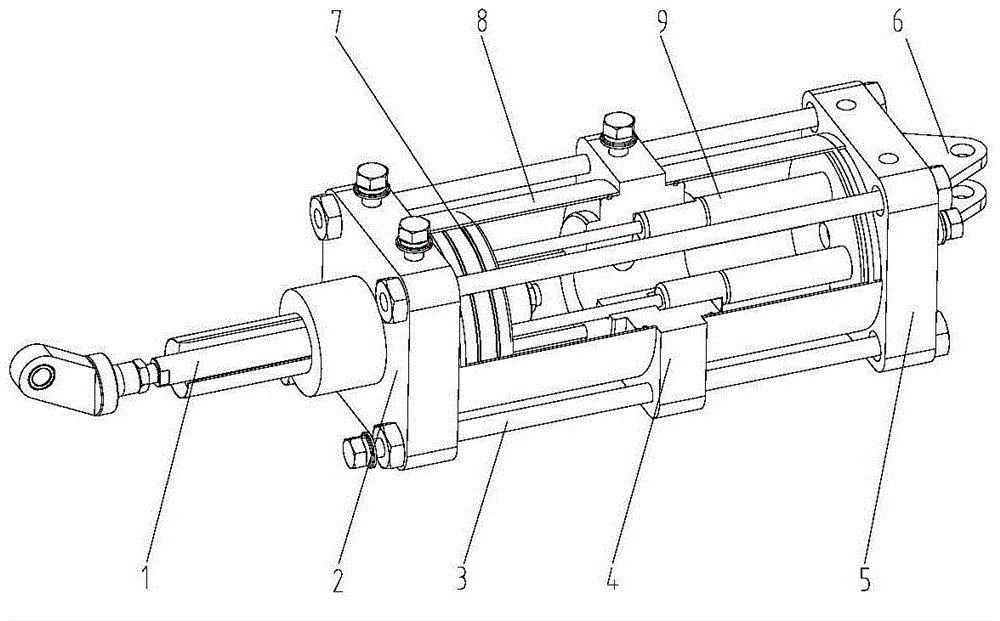

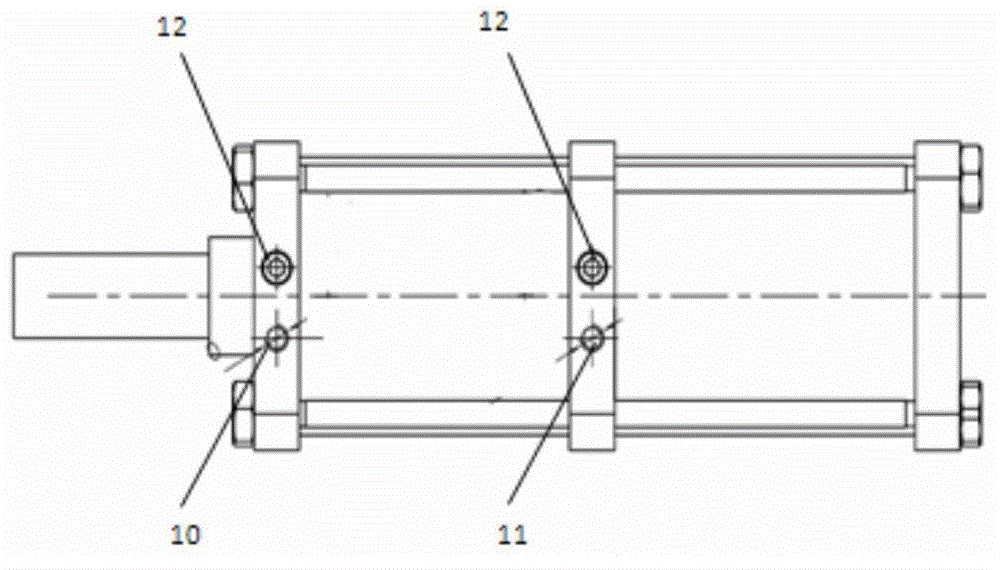

[0025] Such as figure 1 As shown, the reset cylinder is installed on the pantograph chassis, mainly including cylinder body 8, front end cover 2, transition end cover 4, rear end cover 5, primary piston 7, secondary piston 1, mounting seat 6, , the pull rod 3 and the nitrogen spring 9 fixed between the primary piston and the cylinder head;

[0026] Wherein said front end cover 2 is provided with air inlet 10, when air inlet 10 air intake, primary piston 7 overcomes nitrogen spring 9 and moves toward rear end cover 5, and primary piston 7 movement limit passes transition end cover 4 Realize; one end of the nitrogen gas spring 9 is connected to the rear end cover 5, and one end is connected to the primary piston through the transition end cover 4;

[0027] When the cylinder is exhausted, the nitrogen spring 9 is in the reset state, pushing the primary piston 7 to move towards the front end cover of the cylinder;

[0028] The first-stage piston 7 is linked with the second-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com