Force bearing device based on annularly-distributed multistage bearing

A distributed and bearing technology, which is applied in the direction of bearings, shafts and bearings, rolling contact bearings, etc., can solve the problems of equipment volume and weight increase, and achieve the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with accompanying drawings and examples.

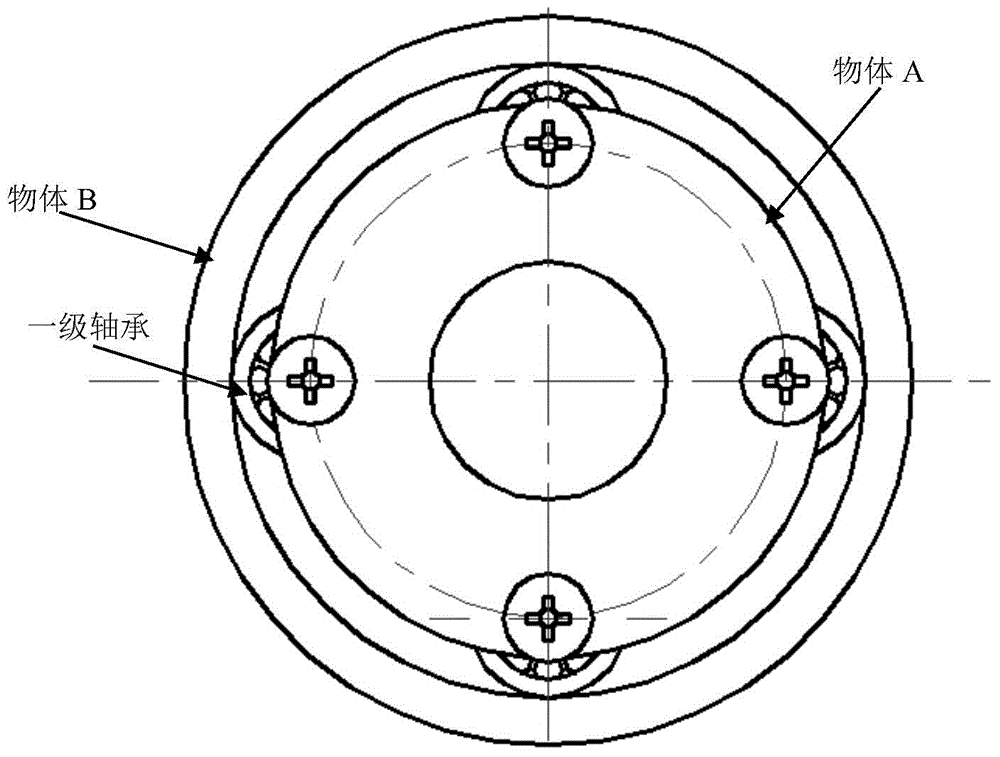

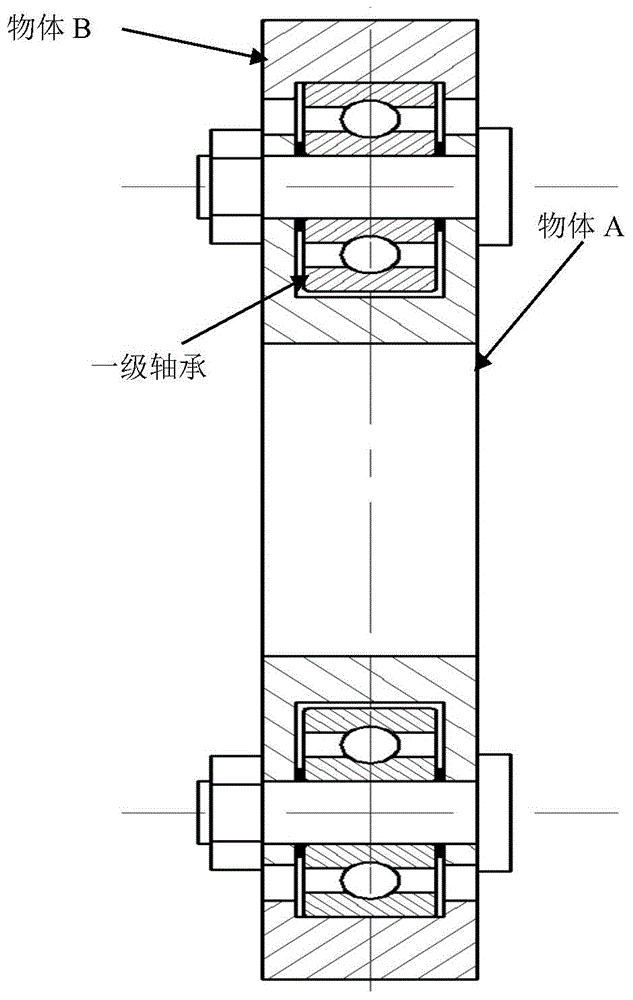

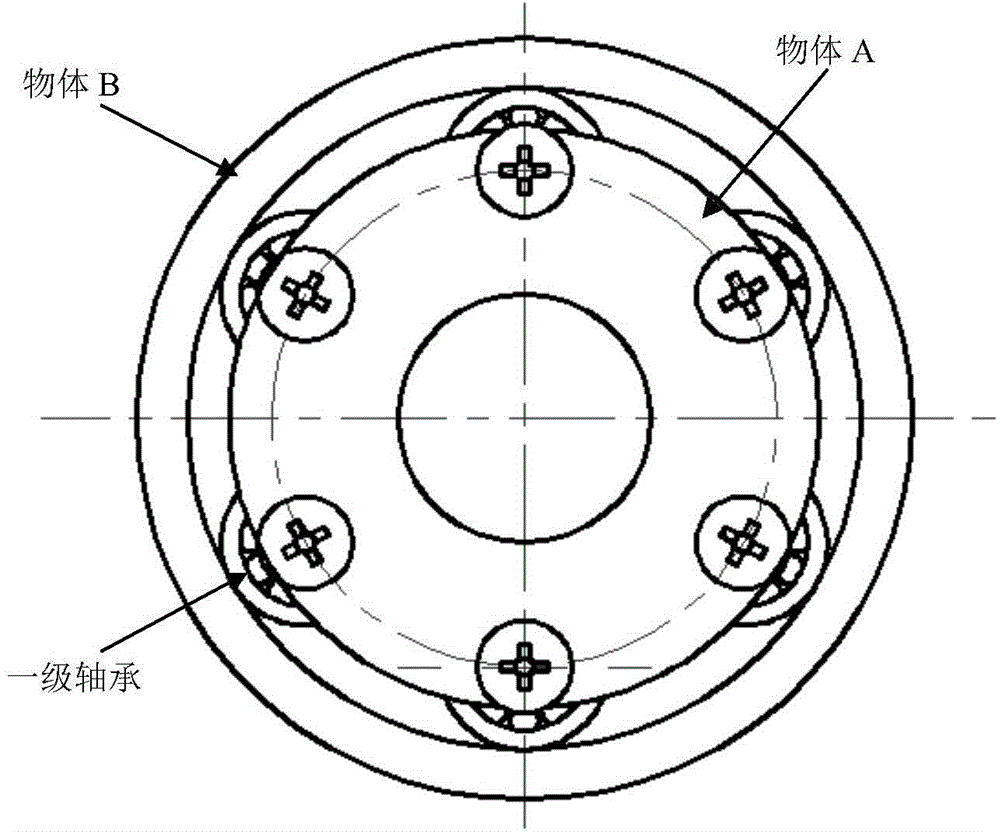

[0016] When the two relatively rotating objects A and B are large, if ordinary bearings are used, the volume and weight of the bearings will be large. The ordinary bearing is the bearing connecting objects A and B in the traditional technology, and is called a primary bearing. Adopting the technical scheme of the invention reduces the volume and weight of the bearing. By adopting the technical solution of the present invention, the two relatively rotating objects A and B can be regarded as the inner ring and the outer ring of the secondary bearing respectively, and a plurality of small primary bearings are evenly distributed on the two relatively rotating objects A Between B and B, a large secondary bearing load-bearing device can be formed. Such a secondary bearing load-bearing device does not need a special secondary bearing inner ring and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com