Hydraulic type belt pulley automatic tensioning device

A technology of automatic tensioning device and pulley, which is applied in the direction of fluid pressure actuating device, transmission device, belt/chain/gear, etc., can solve the problems of inability to realize self-adaptive tensioning, and achieve reasonable design, wide application range and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

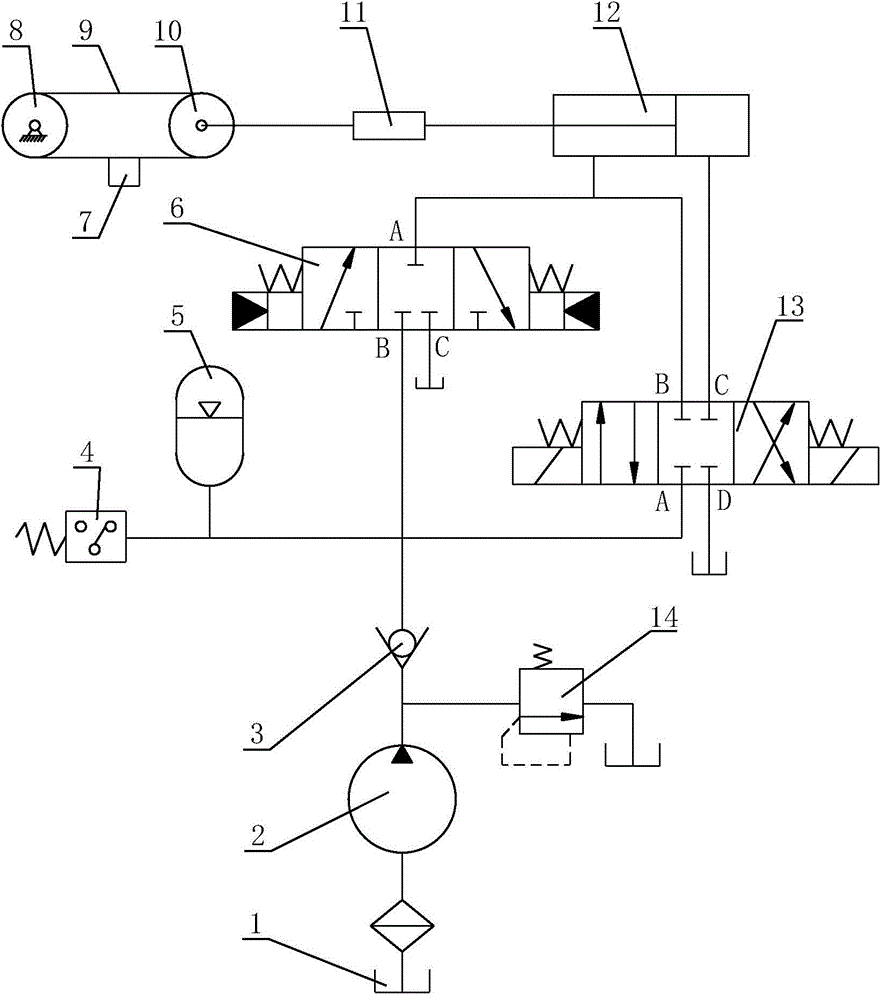

[0019] Such as figure 1 A hydraulic belt pulley automatic tensioning device shown includes a hydraulic cylinder 12 for adjusting the position of the pulley 10 so that the belt 9 reaches a proper tension position and a hydraulic pump 2 for providing high pressure hydraulic oil to the hydraulic cylinder 12 , It also includes a pressure relay 4, an accumulator 5 for replenishing oil for the hydraulic pipeline and maintaining a stable pressure in the hydraulic pipeline, and a device arranged at the outlet of the hydraulic pump 2 to control the maximum tension of the belt 9 Overflow valve 14; the oil outlet of the hydraulic pump 2 is respectively connected with the first working port of the electro-hydraulic servo valve 6 and the first working port of the electromagnetic reversing valve 13, and the second working port of the electro-hydraulic servo valve 6 And the second working port of the electromagnetic reversing valve 13 are in communication with the rod cavity of the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com