Variable-section self-locking leakage prevention device for large opening of internal-pressure vessel

A technology of internal pressure vessel and variable cross-section, which is applied in the field of leakage prevention, and can solve problems such as the inability to ensure the circumferential uniformity of flange edge compression, the difficulty of sealing the large opening end face of the internal pressure vessel, and the impact of bolts on the sealing effect, etc., to achieve structural Compact, easy to manufacture and install, good fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

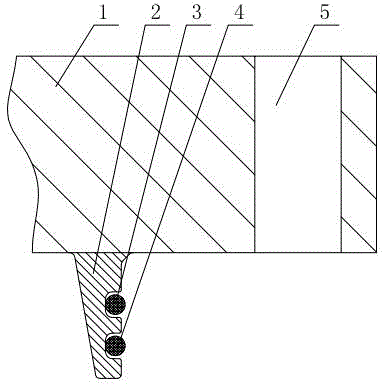

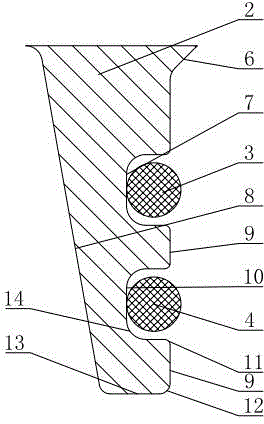

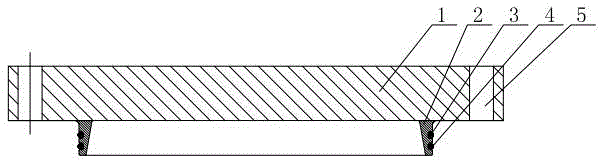

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the variable-section self-locking anti-leakage device of the large opening of the internal pressure vessel of the present embodiment includes a flange flat cover 1, and a variable-section sealing ring 2 extends from the bottom of the flange flat cover 1, and the variable-section sealing ring 2 is Axisymmetric short cylindrical structure, the radial wall thickness of the variable cross-section sealing ring 2 linearly decreases from the root to the end; one end of the variable cross-section sealing ring 2 forms the internal pressure acting surface 8 of the container, and the other end forms the outer longitudinal sealing surface 9, which is located at the variable cross-section The outer longitudinal sealing surface 9 at the root of the cross-section seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com