Combustor structure of gas water heater and gas water heater

A technology for gas water heaters and combustion chambers, applied in the direction of combustion chambers, combustion methods, combustion equipment, etc., which can solve the problems of large volume and large space occupation of gas water heaters, and achieve the effects of reducing surface temperature and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

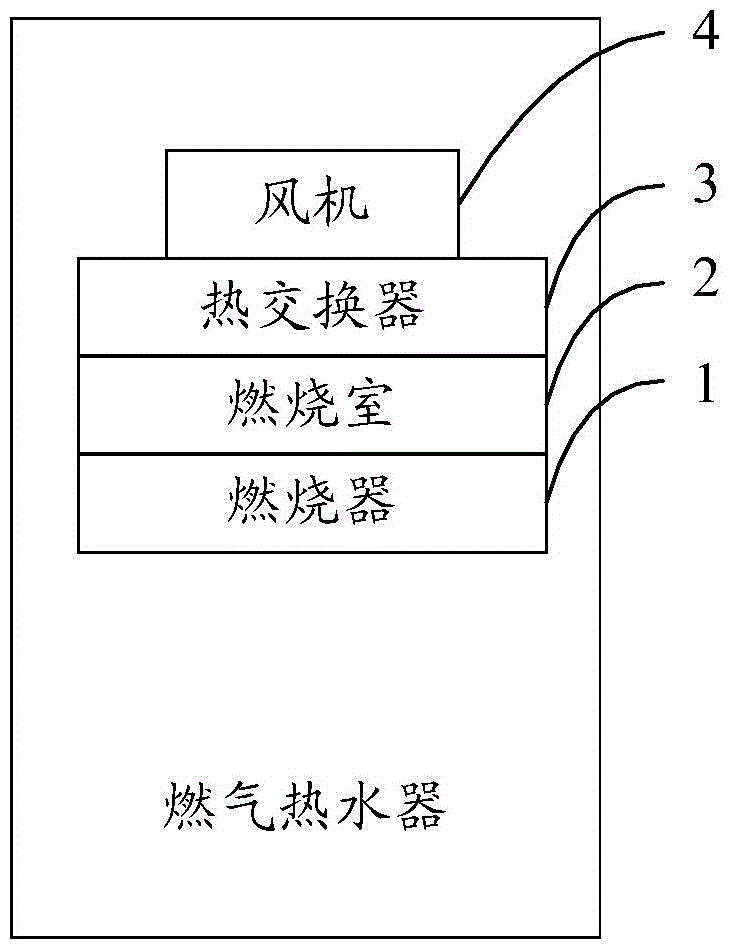

[0024] like figure 1 As shown, the gas water heater involved in the embodiment of the present invention includes a burner 1, a combustion chamber 2, a heat exchanger 3 and a fan 4 arranged sequentially from bottom to top, wherein: the heat generated by the burner 1 is transferred to the heat exchange by the combustion chamber 2 The fan 4 communicates with the inner cavity of the combustion chamber 2. Under the action of the exhaust fan 4, the heat in the combustion chamber 2 can be pumped to the heat exchanger 3 to heat the cold water in the heat exchanger 3 to realize a water heater. The function of generating hot water.

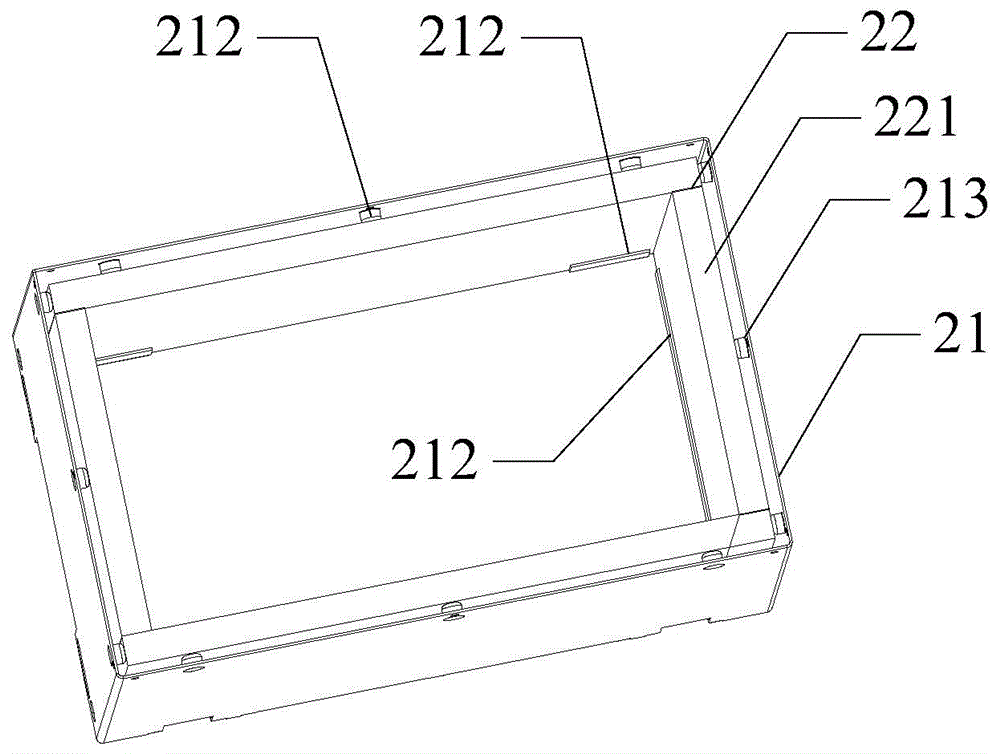

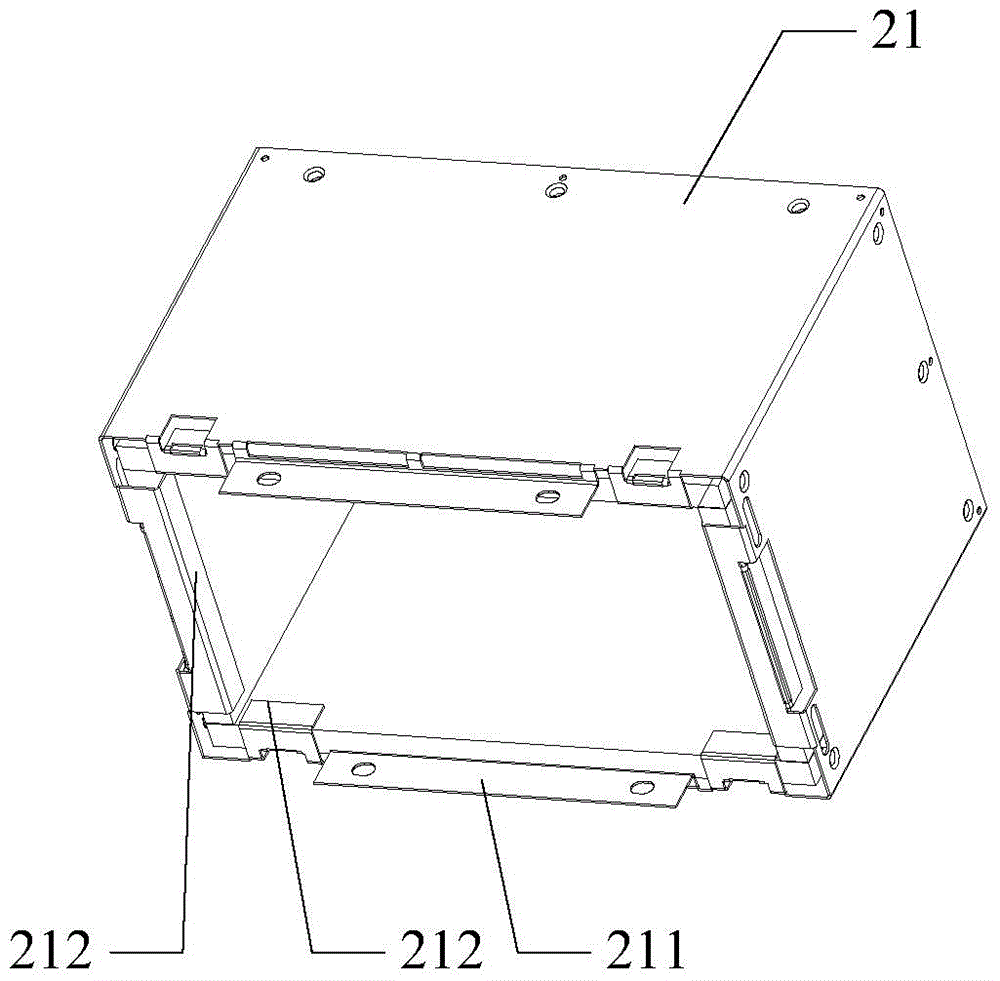

[0025] In order to reduce the surface temperature of the combustion chamber 2 of the gas water heater, the present embodiment adopts the following structure of the combustion chamber 2 .

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com