A testing device for dynamic characteristics of piston-type magneto-rheological fluid extrusion flow

A technology of dynamic characteristics and magnetorheological fluid, which is applied in the direction of fluid dynamics test, measuring device, machine/structural component testing, etc., can solve the problems of lack and limitations of research on the dynamic characteristics of magnetorheological extrusion flow, etc. Achieve the effects of improving processing technology, eliminating impact, and facilitating disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

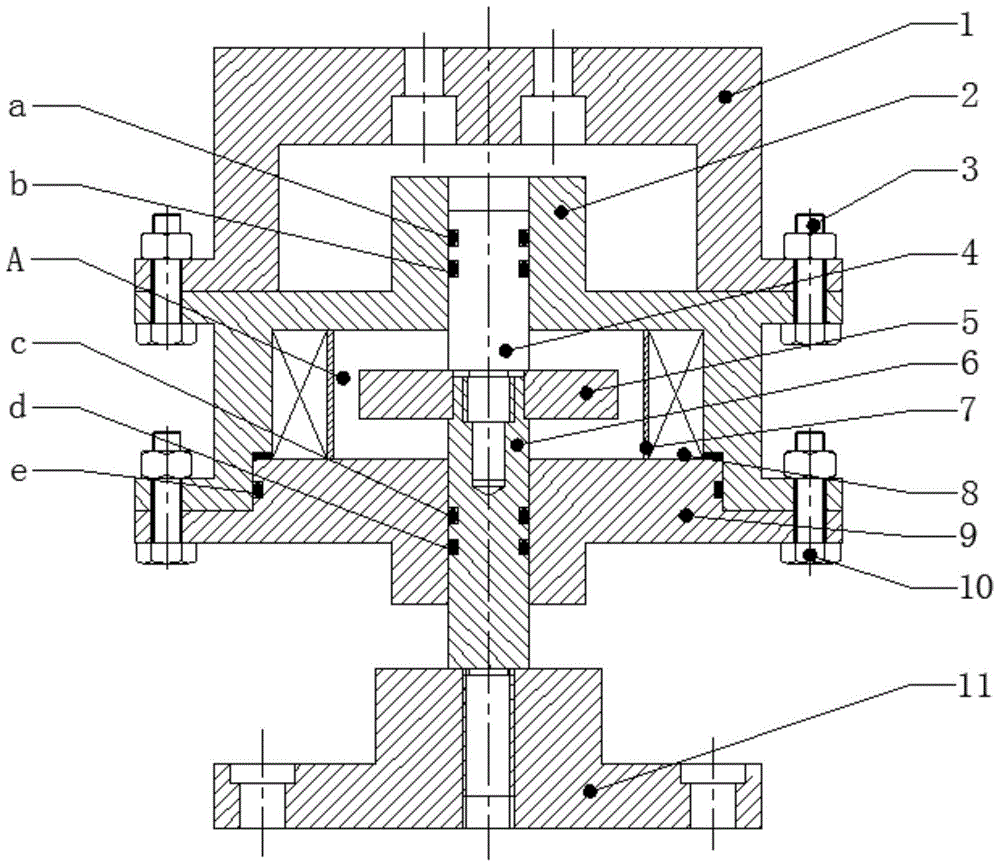

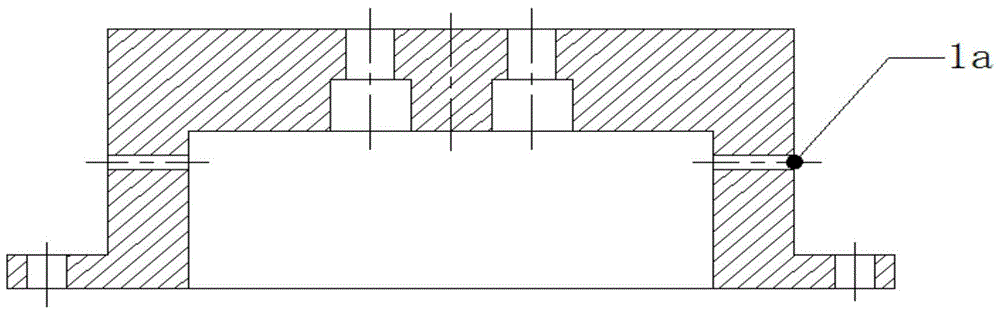

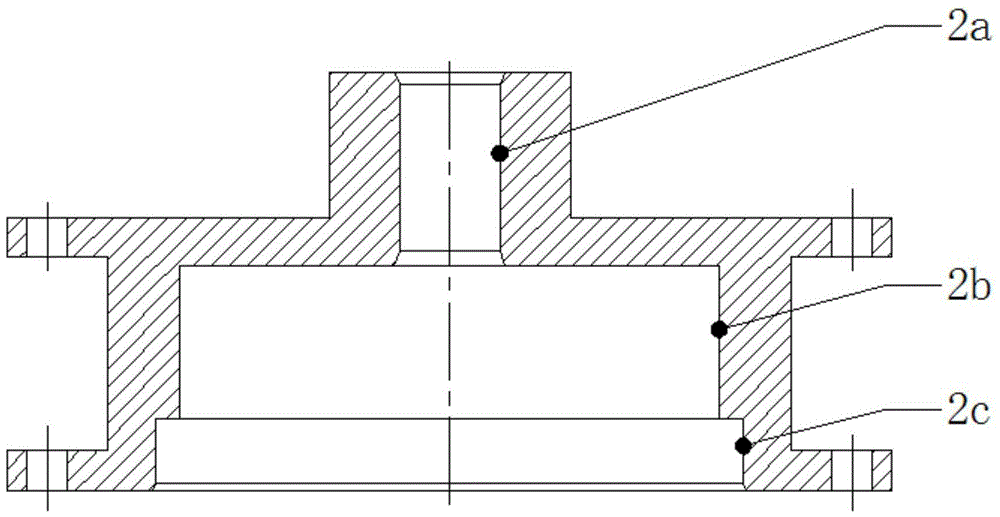

[0047] Such as figure 1 As shown, a piston type magnetorheological fluid extrusion flow dynamics testing device of the present invention includes an upper flange 1, an upper end cover 2, an upper connecting bolt 3, an upper piston rod 4, a piston 5, and a lower piston rod 6. The positioning sleeve 7, the excitation coil 8, the lower end cover 9, the lower connecting bolt 10, the lower flange 11 and a plurality of sealing rings, the airtight working chamber formed by the upper end cover 2, the lower end cover 9 and the positioning sleeve 7 A, the fluid to be tested (magnetorheological fluid or other fluid to be tested) is installed in the working chamber A;

[0048] The piston 5 is arranged in the working chamber A, and the piston 5 is clamped by the shoulders of the upper piston rod 4 and the lower piston rod 6, and the upper piston rod 4 and the lower piston rod 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com