A method for measuring the static contact angle of liquid droplets

A static contact angle and measurement method technology, applied in the field of measurement, can solve problems such as large calculation errors and poor anti-interference ability, and achieve the effects of strong anti-interference ability, increased adaptability range, and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

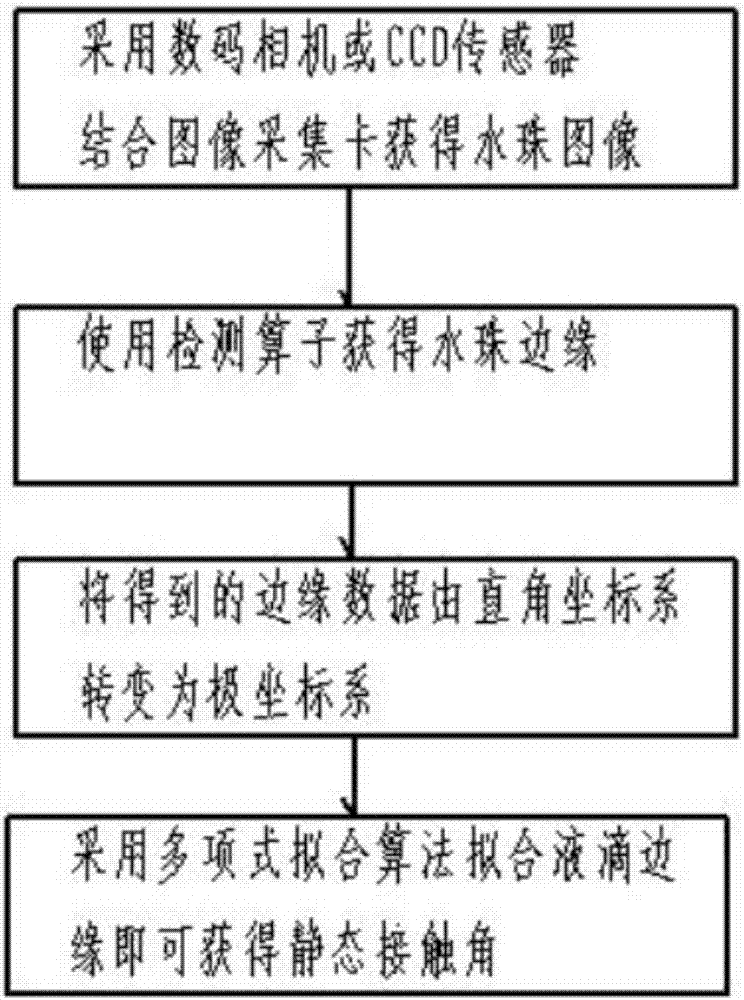

Method used

Image

Examples

Embodiment 1

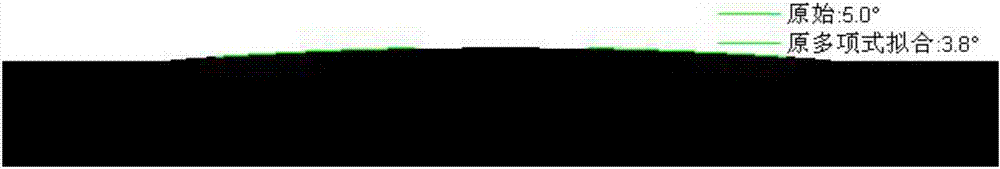

[0067] This embodiment verifies the effect of the simulated water drop image.

[0068] Such as Figure 2a-3a As shown, the simulated water drop image with a contact angle of 5° and a water drop volume of 1 microliter, the calculation accuracy of the original polynomial fitting method is higher, the result is 3.8 degrees, and the error is -1.2 degrees. At this time, the calculation result of the present invention is 3.1 degrees, and the error is only -1.9 degrees, and the obtained edge is in good agreement with the real water drop image, that is to say, the accuracy of the two methods is relatively high at this time.

[0069] Such as Figure 2b-3b As shown, the simulated water drop image with a contact angle of 30° and a water drop volume of 2 microliters, the calculation accuracy of the original polynomial fitting method is higher, the result is 28.5 degrees, and the error is -1.5 degrees. At this time, the calculation result of the present invention is 29.4 degrees, and the...

Embodiment 2

[0074] The water droplet image in this embodiment was obtained on the RTV silicone rubber coating with deionized water droplets, and 1, 2 and 10 microliters of water droplets were dropped into the coatings with different surface treatments, and the images were taken.

[0075] The water droplet edge calculated by the original polynomial fitting method for the above three images is shown in the attached Figure 4a~6a As shown, the water drop edge calculated by the method of the present invention is as attached Figure 4b-6b shown. Considering the real contact angle of the image and the size of the water drop volume, the above three images are the circle fitting method, the circle fitting method and the ellipse fitting method, which have relatively high accuracy. Their calculation and fitting results are as follows: attached Figure 4c-6c shown.

[0076] Such as Figure 4a As shown, the image of water droplets with a volume of 1 microliter, the calculation result of the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com