Hydraulically sealed silage cellar

A technology of silage and water pressure, which is applied in fruit hanging devices, botany equipment and methods, gardening, etc., can solve the problems of waste of resources, insufficient investment funds, and low returns, and achieve the possibility of reducing waste and safe and reliable operation , the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

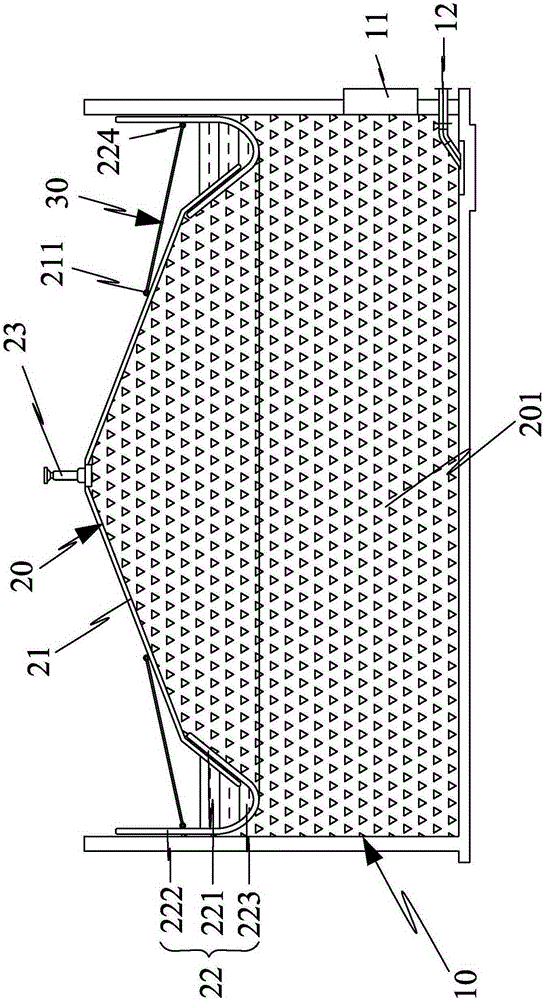

[0026] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a cellar body 10 and a cellar cover 20 .

[0027] Wherein, the cellar body 10 is cylindrical with an open upper end, and the material of the cellar body 10 is cement or metal, and the inner wall of the upper end of the cellar body 10 is flat and smooth. The side wall of the cellar body 10 is provided with a discharge port 11, which can be opened or closed, so that the large-scale discharge operation after silage is very convenient. 11, can continue to maintain the sealing condition, continue to ferment and preserve, and solve the problem of "secondary fermentation" (that is, rapid corruption) of the silage caused by the unavoidable one-time unfeeding method that has been unavoidable in the traditional silage methods, reducing the The possibility of wasting silage; and greatly reducing the possibility of pollution, especially the traditional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com