Method and equipment for preparing low-moisture silage

A technology of silage and manufacturing method, which is applied in the preservation method of animal feed raw materials, molding or processing of animal feed, feed, etc., can solve the problems of high production cost, expensive production equipment, complicated production process, etc., and achieve low cost , save food crops, improve the effect of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

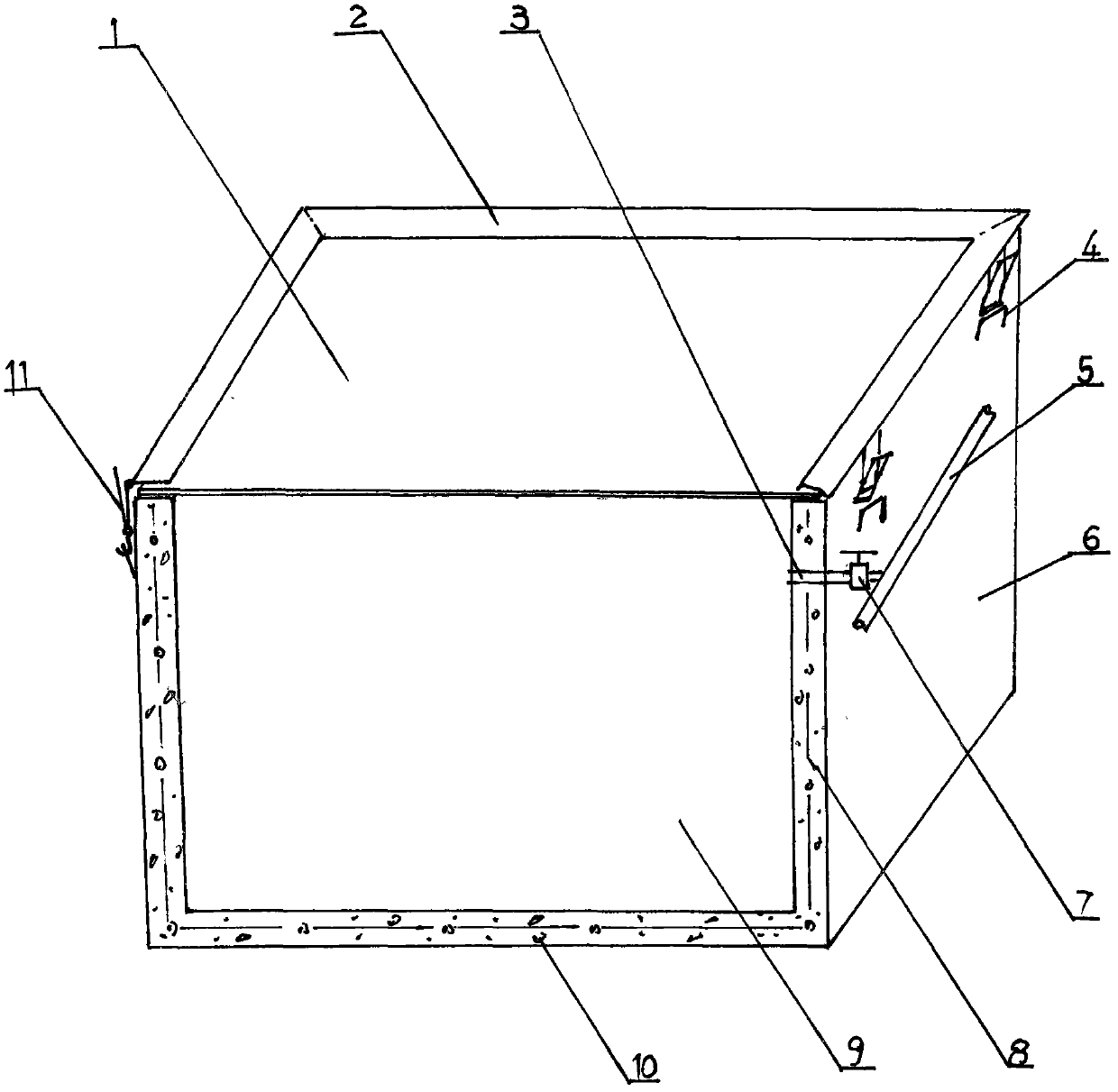

[0021] Embodiment 1: as shown in the figure, a kind of manufacture method of low-moisture silage, the steps are:

[0022] (1) According to the amount of low-moisture silage required by livestock every day, use reinforced concrete to make a silage airtight container suitable for the volume of the amount, and make the same number of days as the cycle of low-moisture silage according to the number of days in the manufacturing cycle of low-moisture silage silage airtight container;

[0023] (2) Preparation of auxiliary materials: drying or drying soybean dregs, distiller's grains, brewer's grains, mushroom chaff after cultivation of edible fungi, and sugar beet dregs, and pulverizing them so that the water content in them is 8-10%, and then making auxiliary materials;

[0024] (3) The fresh green feed with a water content of 70-80% is processed into 0.5-5 cm long and 0.3-1 mm in diameter strands with a kneading machine to make the main ingredient; the fresh green feed is natural g...

Embodiment 2

[0032] Embodiment 2: the daily required low-moisture silage of livestock total amount is 1000kg, and the equivalent volume of 1000kg low-moisture silage is 10m 3 , made of reinforced concrete 10m 3 ~10.1m 3volume of silage airtight containers; the manufacturing cycle of low moisture silage is 45 days, and 45 silage airtight containers of the same size are manufactured. The bean dregs and beet dregs are divided into half, dried or dried, and crushed so that the water content in them is 8-10%, and 169 kg of auxiliary materials are prepared. Be that the alfalfa grass of 70~80% is 70~80%, half and half of green grass, process into 0.5~5cm long, the thread-like section of diameter 0.3~1mm with kneading machine, make main ingredient 800kg. After testing trace elements such as vitamin B, lysine, iron, zinc, iodine, and magnesium in the above-mentioned feed, 1kg of thiamine hydrochloride for livestock, 2kg of lysine for livestock, 2kg of ferric chloride for livestock, and zinc sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com