Method for producing fuel ethanol by fermenting racahout

A technology of fuel ethanol and acorn powder, applied in the direction of microorganism-based methods, biofuels, biochemical equipment and methods, etc., can solve the problems of complex refining process and high cost, improve economy, simplify production process, and save fossils fuel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 500mL LYPD medium, the medium components are: glucose 2%, peptone 2%, yeast extract 1%. Sterilized for later use. Add 1-2 loops of bacteria sludge from FB-E slant seeds to sterilized 500mL YPD medium, and cultivate overnight at 32°C to the end of logarithmic phase to obtain activated FB-E yeast seeds.

Embodiment 2

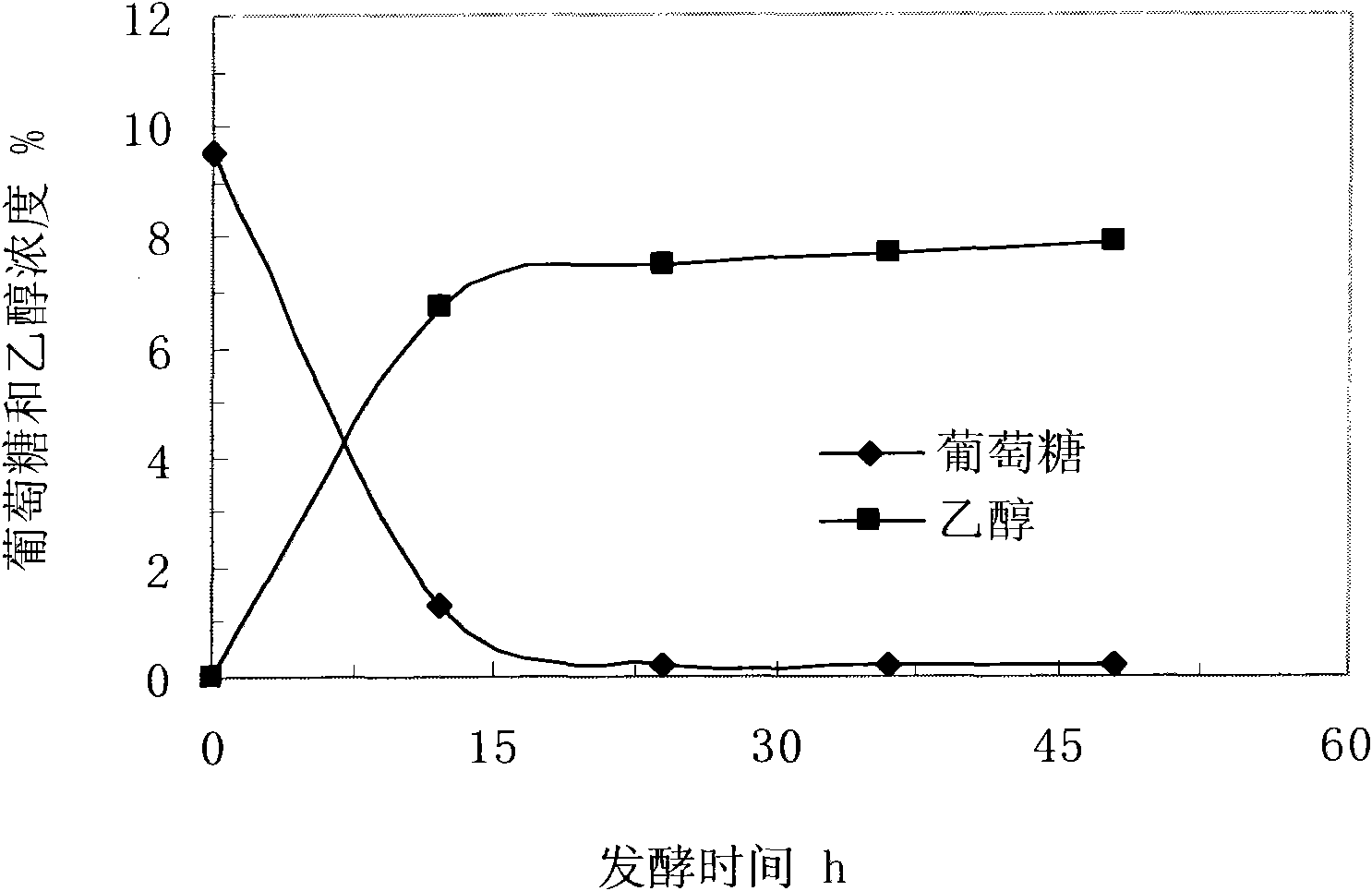

[0023] Add 2.5L tap water, 0.6mL high-temperature amylase (40000U / mL) to 1kg acorn powder, liquefy at 100°C for 1 hour, cool down to 50°C, add 4g starch glucoamylase (30000U / g), 1g commercial cellulase (200U / g ), incubate for 14h, measure the glucose concentration as 125g / L, add 500mL nutrient solution (5% yeast extract), 200mL Saccharomyces cerevisiae FE-B seeds, 32 ℃, 500rpm, pH 5.0 fermentation, see figure 1 . From figure 1 It can be seen that the ethanol concentration basically reached the maximum after 24 hours of fermentation, and the mass concentration of ethanol at 48 hours was 7.88%, which was only 5.8% higher than the mass concentration of 7.45% at 24 hours. The mass yield of ethanol in 24h fermentation is 23.8%, and the mass yield of ethanol in 48h is 25.2%, which is equivalent to producing 1 ton of ethanol from 4 tons of acorn powder.

Embodiment 3

[0025] Add 2.5 tons of tap water to 0.8 tons of acorn powder, 25kg of yeast extract, 0.6L of high-temperature amylase (40000U / mL), liquefy at 100°C for 1 hour, cool down to 50°C, add 4kg of starch glucoamylase (30000U / g), and 1kg of commercial cellulose Enzyme (200U / g), incubated for 20h, 500L of Saccharomyces cerevisiae FE-B seeds, fermented at 32°C, 200rpm, pH 5.0. After 24 hours of fermentation, the ethanol concentration basically reached the maximum value, and the ethanol mass concentration was 8.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com