Antistatic, antibacterial and heat-moisture comfortable summer uniform fabric and preparation process for same

A technology of preparation technology and comfort, which is applied in the field of antistatic, antibacterial, heat-humid comfort summer uniform fabrics and its preparation technology, can solve the problems that summer uniform fabrics do not have heat-humid comfort, and achieve outstanding heat-humid comfort, Dyeing and finishing process optimization, the effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

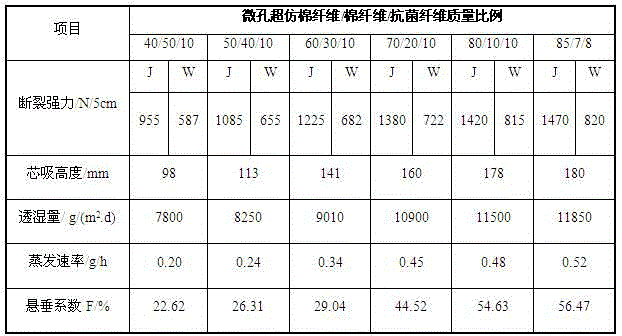

Embodiment 1

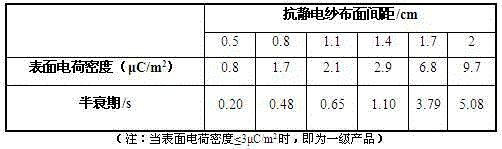

[0033] An antistatic, antibacterial, heat-humid and comfortable summer uniform fabric: the mass ratio of microporous cotton-like polyester fiber, cotton fiber, and nano-layered silver-based antibacterial polyester fiber is 60: 30: 10; nylon-based antistatic The embedding distance of the composite fiber (20D / 16f) in the fabric is controlled at 0.8 cm.

[0034] The preparation method of the microporous super-cotton imitation polyester fiber is as follows: at room temperature, the microporous polyester fiber is put into the fiber opening liquid at a bath ratio of 1:20, the temperature is raised to 100° C., and the temperature is kept for 60 min, and then Rinse twice with water at 95°C and twice with water at 25°C to obtain microporous super-cotton-like polyester fibers; the content of sodium hydroxide in the fiber opening solution is 15g / L, and the alkali weight reduction accelerator TF The content of -118L is 0.1g / L, and the reduction rate is controlled at 12%.

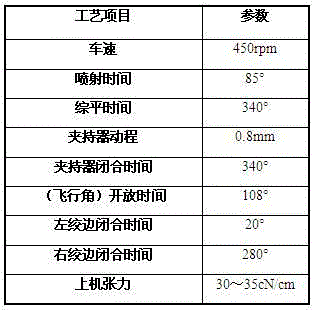

[0035] Outerwe...

Embodiment 2

[0042] An antistatic, antibacterial, hot and humid comfortable summer uniform fabric: the mass ratio of microporous cotton-like polyester fiber, cotton fiber, and nano-layered silver-based antibacterial polyester fiber is 70:20:10; nylon-based antistatic The embedding distance of the composite fiber (20D / 16f) in the fabric is controlled at 1.1 cm.

[0043] The preparation method of the microporous super-cotton-like polyester fiber is as follows: at room temperature, the microporous polyester fiber is put into the fiber opening liquid at a bath ratio of 1:20, the temperature is raised to 120° C., and the temperature is kept for 40 min, and then Rinse twice with water at 95°C and twice with water at 25°C to obtain microporous super-cotton-like polyester fibers; the content of sodium hydroxide in the fiber opening solution is 8g / L, and the alkali weight reduction accelerator TF The content of -118L is 0.2g / L, and the reduction rate is controlled at 8%.

[0044] Shirt Fabric: Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com