Method for preparing multifunctional multilayer micro/nanometer core-shell structure

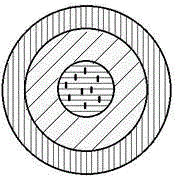

A nano-core-shell and core-shell structure technology is applied in the field of preparation of micro/nano materials, which can solve the problems of difficulty in controlling particle morphology, restricting the types of materials used, easy agglomeration of particles, etc., and achieves good application prospects, strong applicability, and operation. Process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

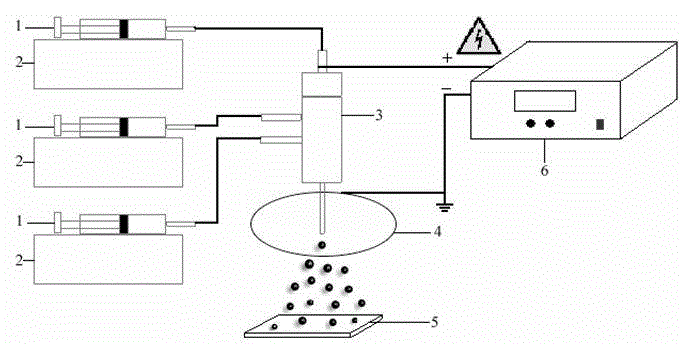

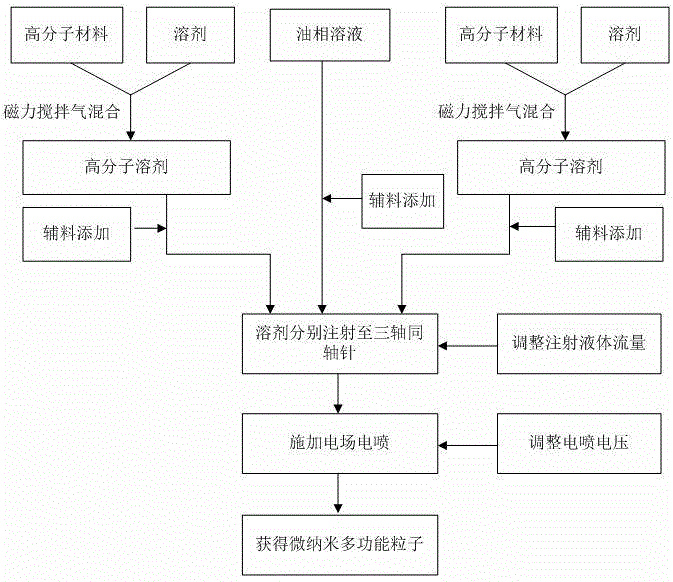

[0058] Experimental device according to figure 1 Build as shown. Experimental materials Polyε-caprolactone (average molecular weight 45,000) and dye rhodamine B were purchased from Aldrich Co. (USA). Prepare a solution with a mass fraction of PCL of 5%, use dichloromethane as a solvent, and stir on a magnetic stirrer at a speed of 200 r / min for 20 minutes to obtain a colorless and transparent solution, and add 0.05 mg of the dye Rhodamine B to it , after stirring evenly, it was used as the inner layer solution of electrospray; olive oil was not treated as the middle layer solution of electrospray; a solution with a mass fraction of polyε-caprolactone of 5% was prepared, and dichloromethane was used as a solvent in a magnetic stirrer Stir at a speed of 200 r / min for 20 minutes to obtain a colorless transparent solution, which is used as the outer layer solution of electrospray after being stirred evenly.

[0059] Transfer the prepared electrospray liquid into a syringe (5 ml)...

Embodiment 2

[0061] Prepare a solution with a mass fraction of polyε-caprolactone of 5%, using dichloromethane as a solvent, and stirring at a speed of 200 r / min on a magnetic stirrer for 20 minutes to obtain a colorless and transparent solution, and polyε-caprolactone according to the mass ratio - Caprolactone solution: Fe 3 o 4: Tween 80 = 96:3:1 Stir several materials evenly, this solution is used as the outermost layer solution of EFI; mineral oil is not treated as the middle layer solution of EFI; the mass fraction of polyε-caprolactone is prepared to be 5 % solution of 10 ml, using dichloromethane as a solvent, and adding 0.05 g of paclitaxel drug in it, after stirring evenly, this solution was used as the innermost solution of electrospray.

[0062] Transfer the prepared electrospray solution into a syringe (5 ml), connect it to the outer, middle and inner channels of the ternary coaxial needle through silicone tubes, adjust the speed of the syringe pump, and adjust the flow rates ...

Embodiment 3

[0064] Prepare a solution with a mass fraction of polylactic acid-glycolic acid copolymer of 5%, using dichloromethane as a solvent, and stirring at a speed of 200 r / min on a magnetic stirrer for 20 minutes to obtain a colorless and transparent solution, which is used as an electrospray The outermost layer solution; the silicone oil is not treated as the middle layer solution of electrospray; prepare a solution with a chitin mass fraction of 7%, use trifluoroacetic acid as a solvent, and stir for 20 minutes at a speed of 200 r / min on a magnetic stirrer , to obtain a colorless transparent solution, and according to the mass ratio of chitin solution: Fe 3 o 4 : Tween 80 =96:3:1 Stir several materials evenly, this solution is used as the innermost solution of electrospray.

[0065] Transfer the prepared electrospray liquid into a syringe (5 ml), and connect it to the outer, middle, and inner channels of the three-way coaxial needle respectively through the silicone tube. The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com