Single-side opening machine tool chip removal guide rail

A single-sided, single-rail technology, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of low chip removal efficiency, chip residue, and poor cleaning effect, so as to avoid motion interference, The effect of low manufacturing cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

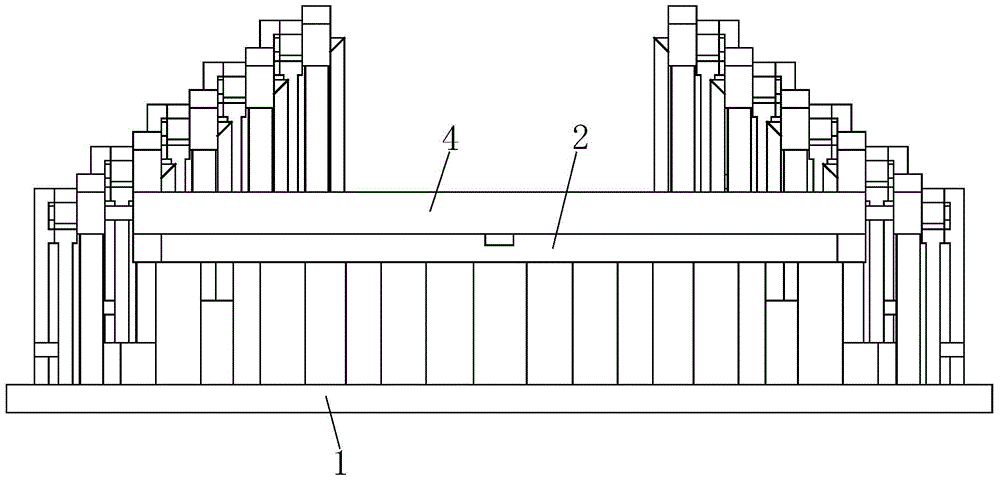

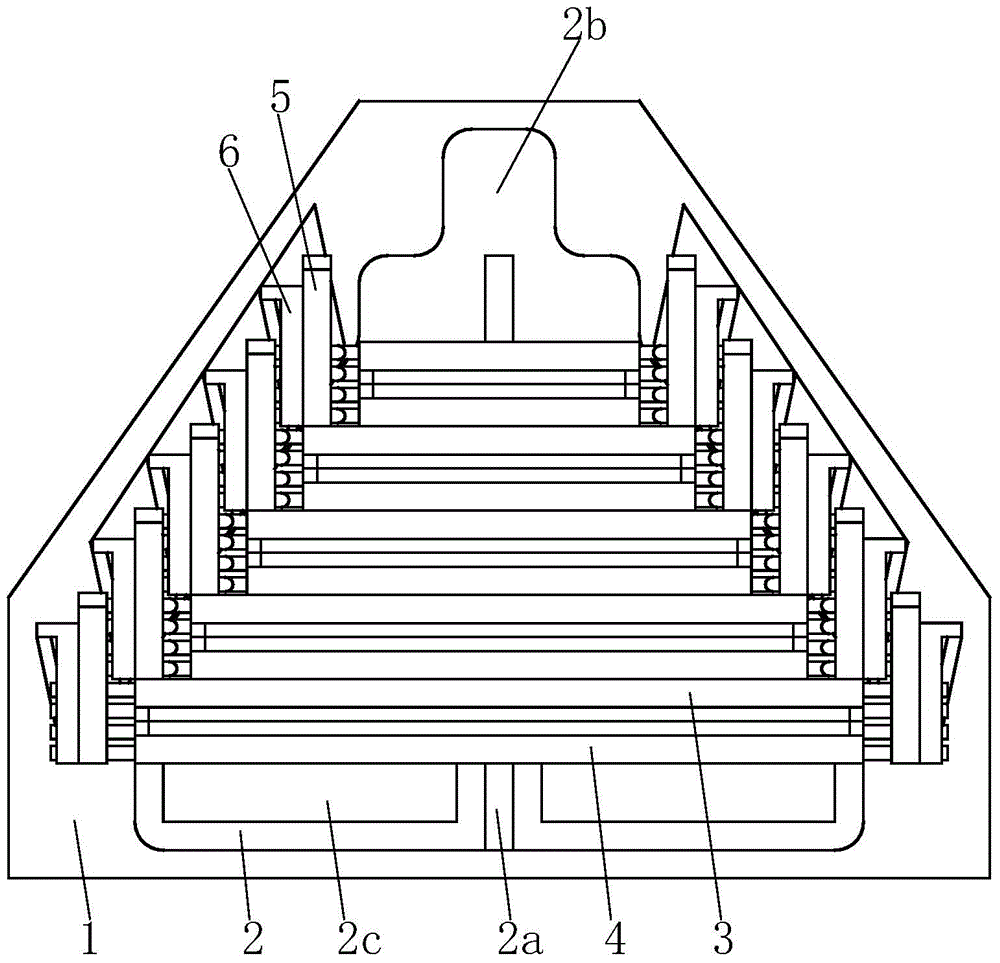

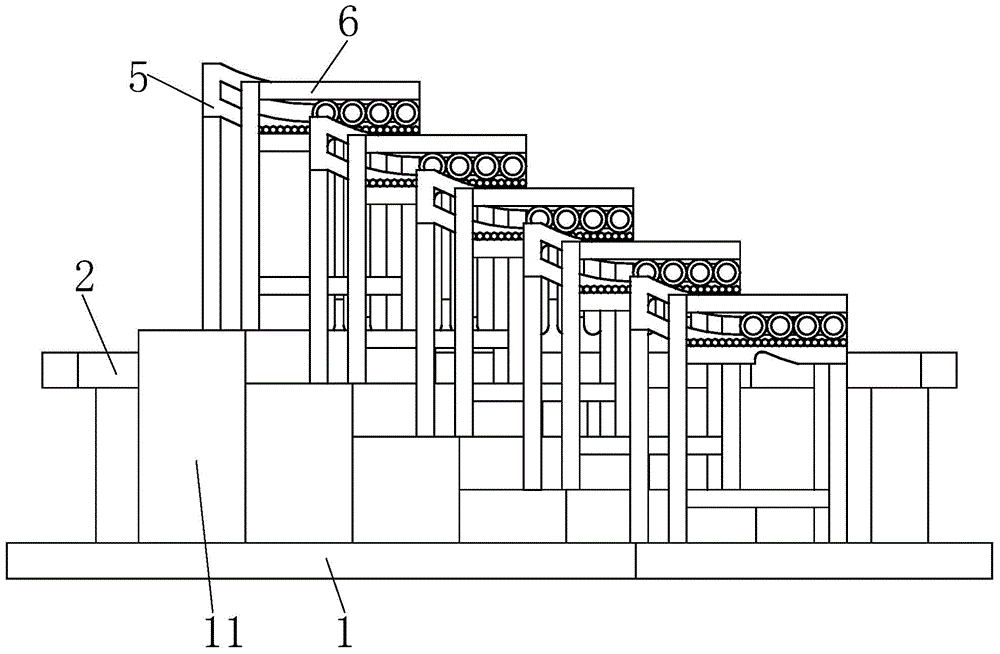

[0022] Such as Figure 1 to Figure 7 As shown, a single-side single-opening machine tool chip removal guide rail includes a bottom plate 1, a base 2 is installed above the bottom plate 1, and a bottom bracket 2b is provided at the rear end of the base 2, and the bottom bracket 2b For installing external drive equipment, the left and right sides of the base 2 are symmetrically provided with a gradient type reference correction device, and the upper end surface of the base 2 is provided with a base chute 2a along the width direction of the base 2, so The upper end of the base 2 is provided with chip removal holes 2c, and the chip removal holes 2c are symmetrically distributed on the left and right sides of the base chute 2a. Combined gradient base rails. The combined gradient base rails ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap