Two-dimensional uncoupled nano-scale motion platform mechanism

A motion platform, non-coupling technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve processing, assembly technology constraints, low displacement resolution, multi-dimensional Motion coupling and other issues, to achieve the effect of improving assembly and controllability, reducing design difficulty, and smooth and precise guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

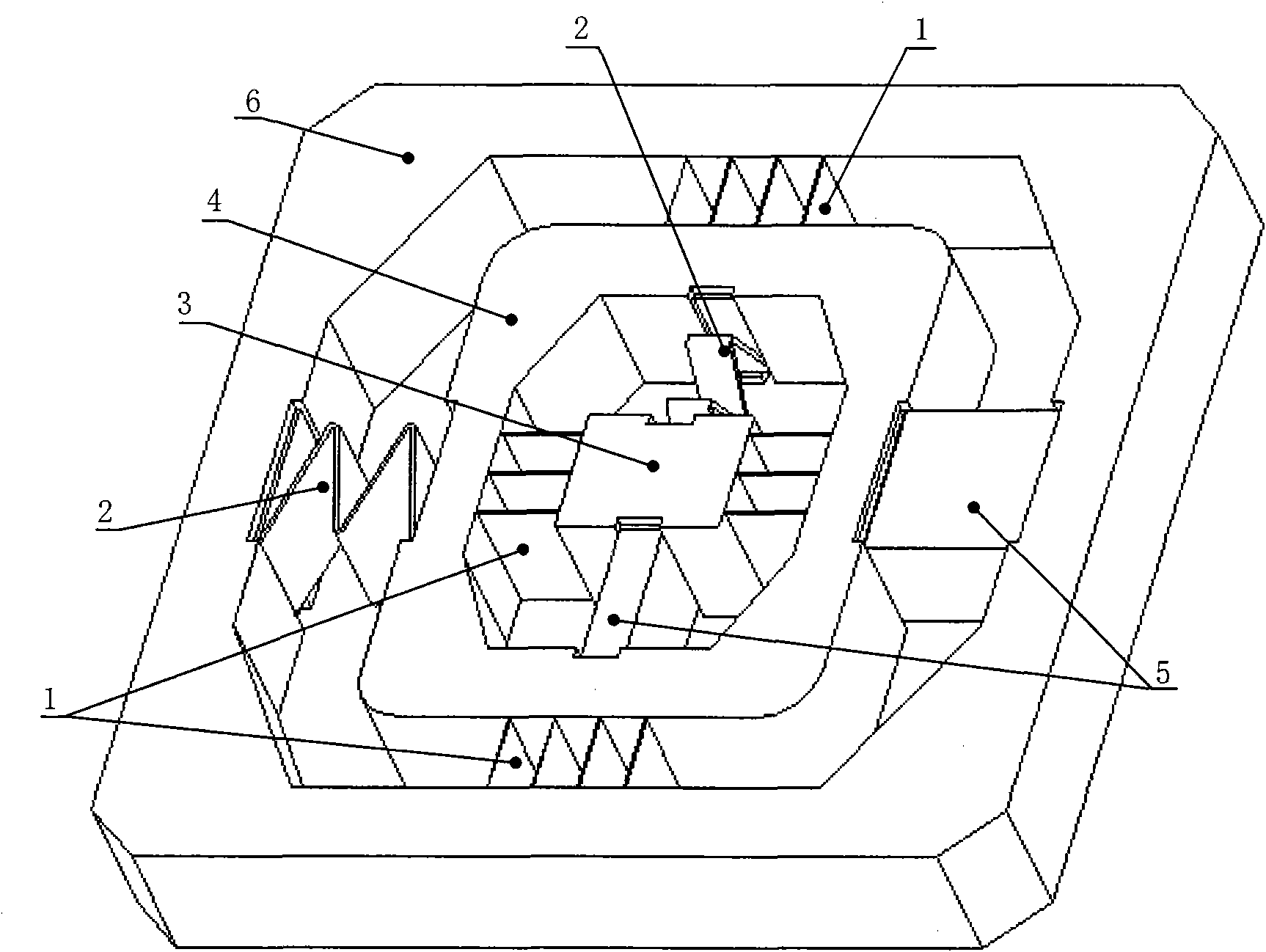

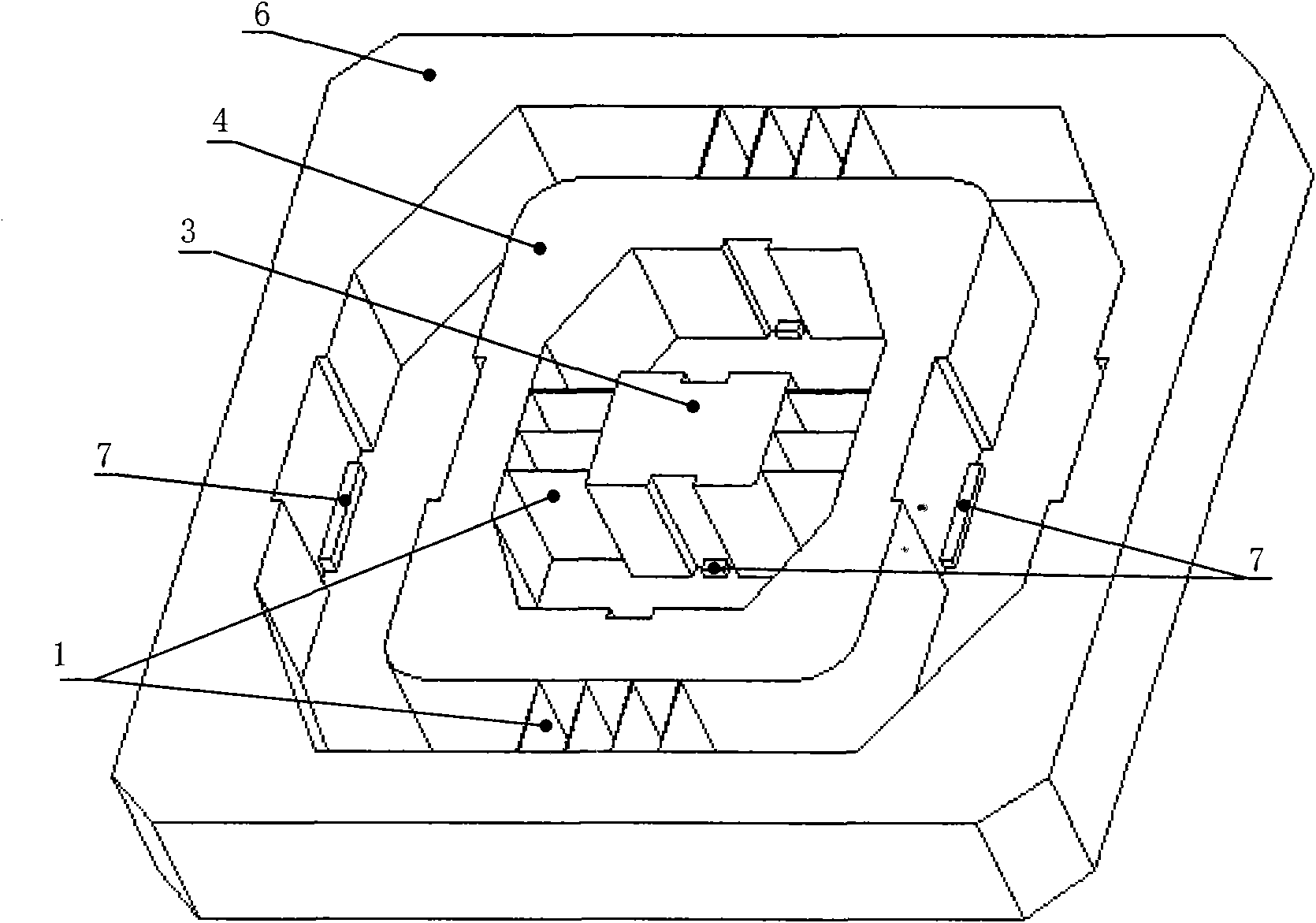

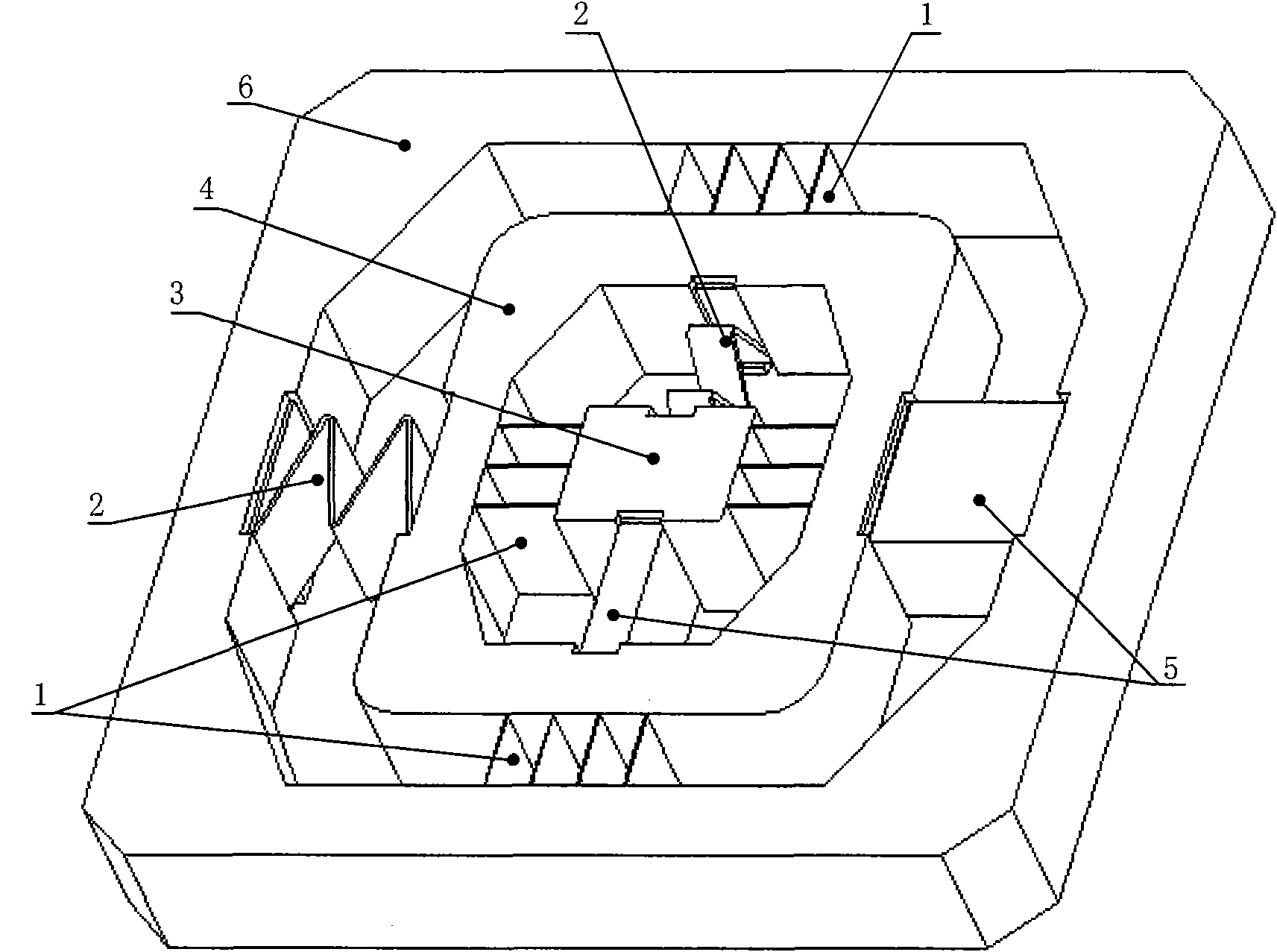

[0018] Example: such as figure 1 , figure 2 As shown, the present invention includes a moving platform 3, an inner frame 4, and an outer frame 6, which are staggered and connected through flexible guiding ribs 1 to form an integrated structure, that is, a symmetrical frame of the inner frame 4 is connected with the moving platform 3 with A flexible guiding rib 1 is connected between another symmetrical frame and the outer frame 6, and a flexible guiding connecting rib is connected between the moving platform 3 and the inner frame 4, and the other pair of frames between the inner frame 4 and the outer frame 6 are respectively symmetrically arranged. A piezoelectric ceramic driver 5 and a pre-tensioned drive spring 2 are provided, and the piezoelectric ceramic driver 5 is connected with an external controller.

[0019] The flexible guide connecting rib 1 described in this example is composed of a plurality of sheet plates juxtaposed, and may have slight deformation during oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com