Rod piece clamping device

A clamping device and rod technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of reducing processing speed, energy waste, etc., and achieve the effect of uniform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

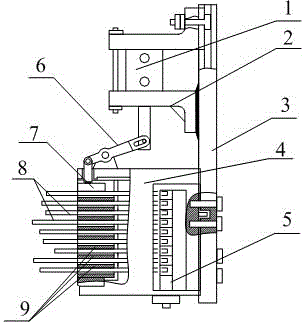

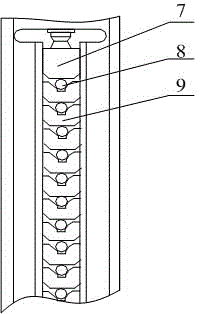

[0017] Such as figure 1 with figure 2 As shown, the rod clamping device includes a base 3, a clamping part arranged on the base 3 for clamping the rod and a power part for providing clamping force, the clamping part includes a clamping table 4, and the clamping table 4 is provided with a track for installing the jaws 9, the width of both sides of the track is less than the width of the jaws 9, the shape of the jaws 9 is V-shaped, and they are embedded in the track one by one in a straight line in the same direction, so that the jaws 9 can be in the same direction. Sliding in the track, multiple jaws are installed on the track in sequence in the same direction. The power component includes cylinder 1, which is installed on the cylinder seat 2. The cylinder seat 2 is two right-angled blocks close to each other, and the right-angled block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com