Manufacturing device and method of steel cord for rubber track

A steel cord and rubber crawler technology, applied in applications, belts, household appliances, etc., can solve the problems of messy arrangement, high labor intensity, low efficiency, etc., and achieve the effects of prolonging the service life, realizing automatic production, and uniform rubber coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

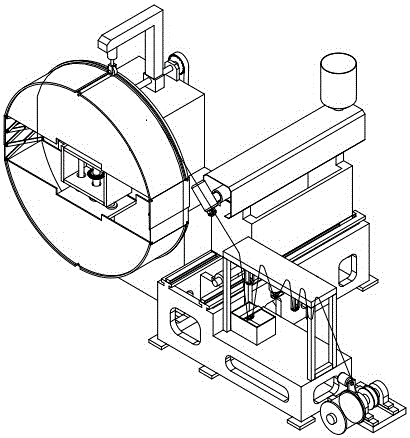

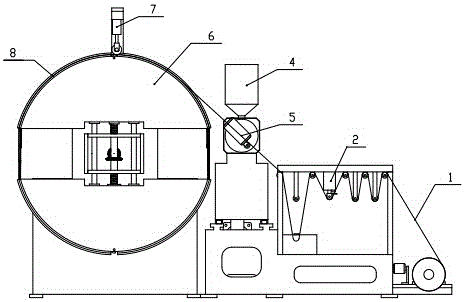

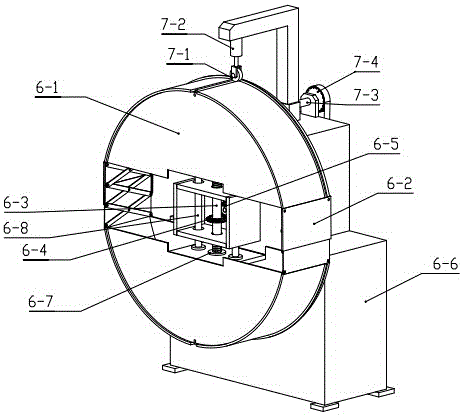

[0040] Such as figure 1 , figure 2 As shown, the manufacturing device of the steel cord for rubber crawlers of the present invention includes a steel wire tensioning mechanism 2, an extruder 4, and a drum mechanism 6. The steel wire rope 1 bypasses the steel wire tensioning mechanism 2, so that the steel wire rope 1 has tension; Pass through the die 5 of the extruder 4 to coat the surface of the steel wire rope 1 with a layer of rubber to become a rubberized cord 8;

[0041] The drum mechanism 6 is arranged on the frame 6-6, and the drum mechanism 6 can rotate around its horizontal axis; the drum mechanism 6 winds the rubberized cord 8 onto the rotating cylinder 6-1 during the rotation process;

[0042] The extruder 4 is provided with an extruder moving mechanism; the extruder moving mechanism can drive the extruder 4 to move along the axial direction of the drum mechanism 6;

[0043] A pressing mechanism 7 is arranged above the roller mechanism 6; the pressing mechanism 7 presses o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com