A stencil-pressing roller mechanism for a carton printing die-cutting machine

A carton printing and die-cutting machine technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of high frequency of use of die rollers, complex structure of die rollers, and difficult maintenance of faults, so as to improve work efficiency, The effect of strong adaptability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

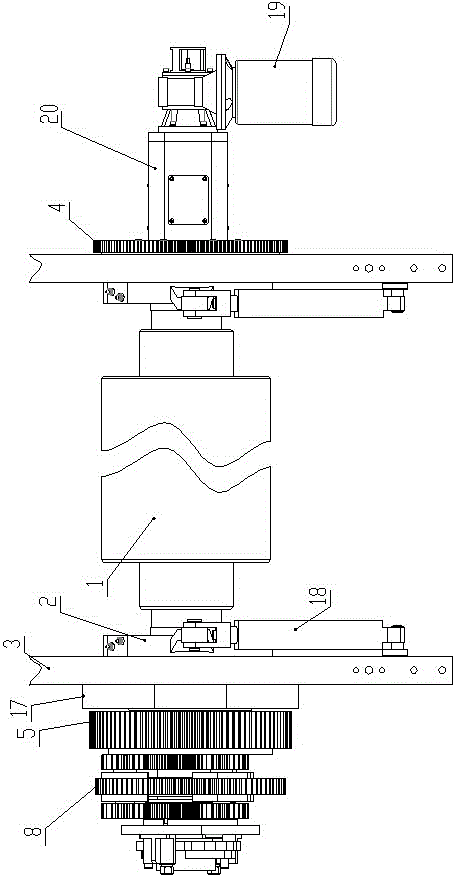

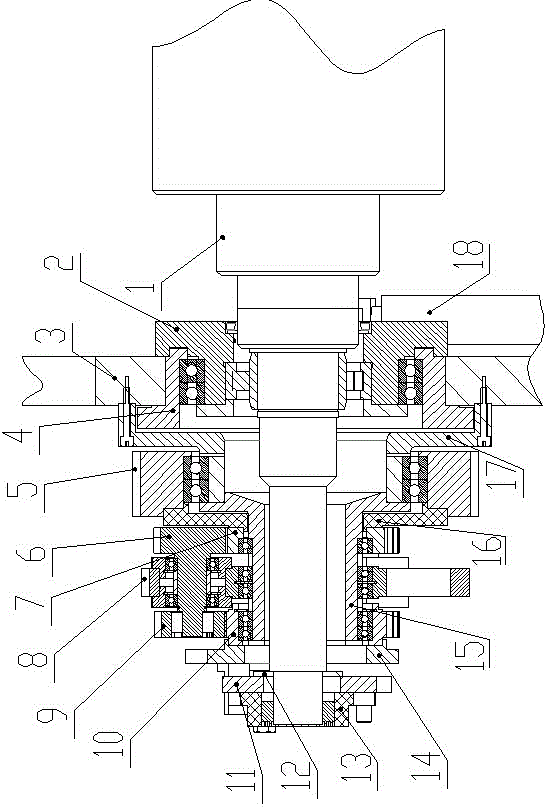

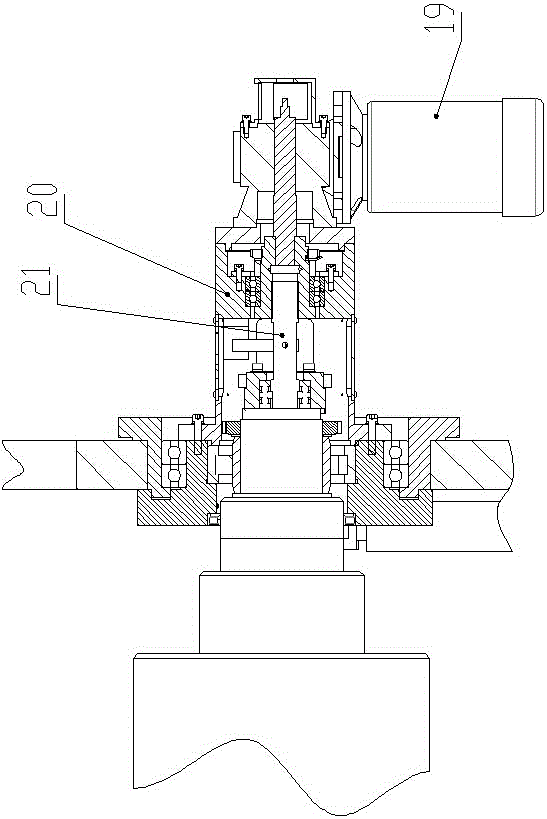

[0019] Such as figure 1 , figure 2 , image 3 As shown, the utility model provides a carton printing die-cutting machine stamping roller mechanism, including two side wallboards 3 and the central rotary connection of the plate roller 1, the upper part is provided with stamping rollers and other rollers, through the transmission mechanism to drive each Roller rotation, the improvement is that the shaft of version roller 1 and the wall panels on both sides are respectively rotated and connected to eccentric sleeves 2, and eccentric sleeves 2 are respectively hinged with cylinders 18 to control their rotation. When the arm of the cylinder 18 is stretched out, under the action of the eccentric sleeve 2, the axis center of the plate roller 1 moves up, and the shaft is connected to the power through the half coupling 13. At this time, it is in working condition. When the arm of the cylinder 18 retracts , the shaft center of version roller 1 moves down, and the shaft is disconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com