Brake clutch device of lever block

A technology of clutch device and lever hoist, which is applied to the combination of coupling and brake, hoisting device, brake type, etc., can solve the problems of inconvenient disassembly and assembly of lever hoist, achieve accurate display, prevent misoperation, The effect of reducing relative drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

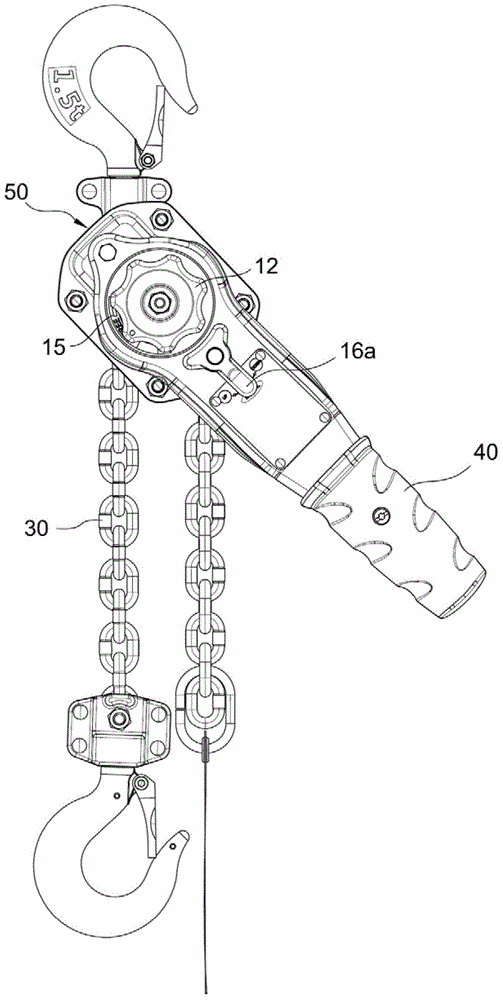

[0025] refer to figure 1 , figure 2 , the lever hoist of the present invention includes a main body 50, and a long shaft 20 passes through the main body 50, and the long shaft 20 is respectively covered with a brake clutch device 10, a wrench 40, a gear transmission mechanism (not shown), and the gear transmission The mechanism is covered with a lifting chain 30, and the brake clutch device 10 is driven by the wrench 40, thereby driving the long axis 20 to rotate. The lifting chain 30 is lifted or lowered, thereby realizing the lifting of the heavy object.

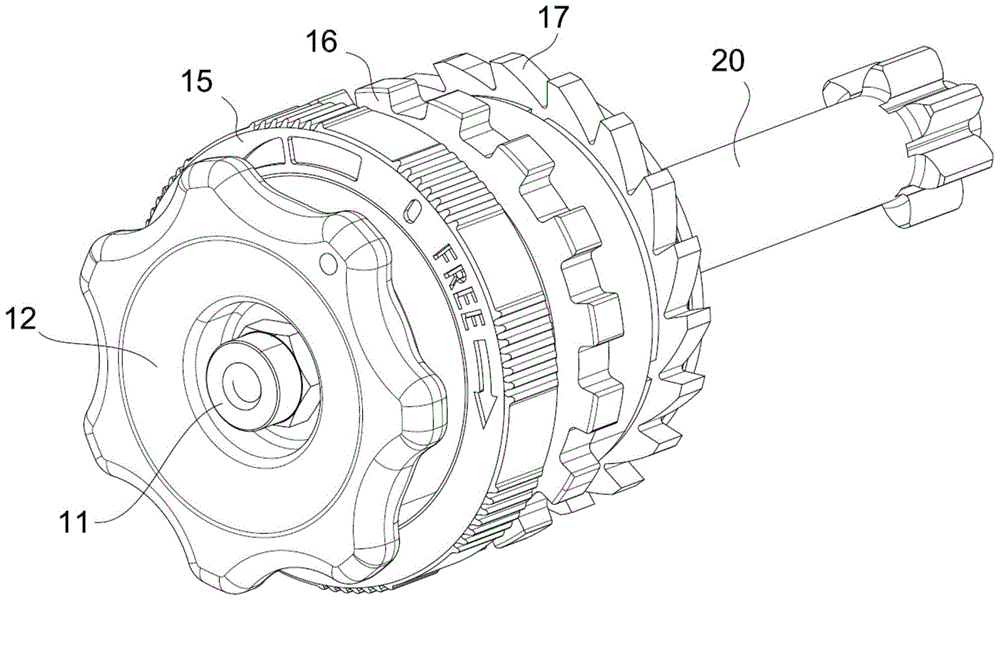

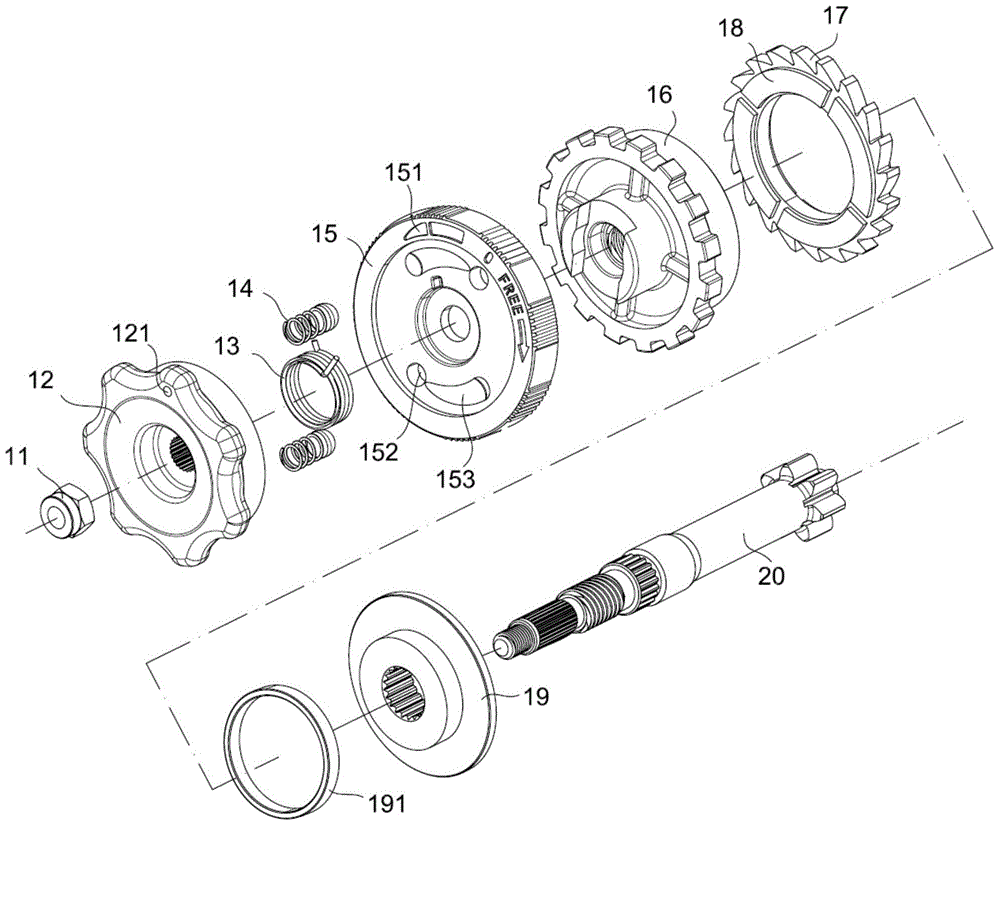

[0026] refer to figure 2 , image 3 , Figure 4 , the brake clutch device 10 of the lever block of the present invention includes a brake seat 19, a brake ratchet 17, a reversing ratchet 16, a torsion spring seat 15, a hand wheel 12 and Fixing part 11, and one end is limited and fixed by brake seat 19, and the other end is limited and fixed by fixed part 11, and brake seat 19 is limited and fixed by the step on long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com