Dual-drive horizontal drive mechanism of stacking machine

A technology of horizontal drive and stacker, applied in the field of stacker, can solve the problems of increasing adhesion, increasing axle load, wheel grinding loss circle, etc., to increase friction, improve driving friction and braking torque improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

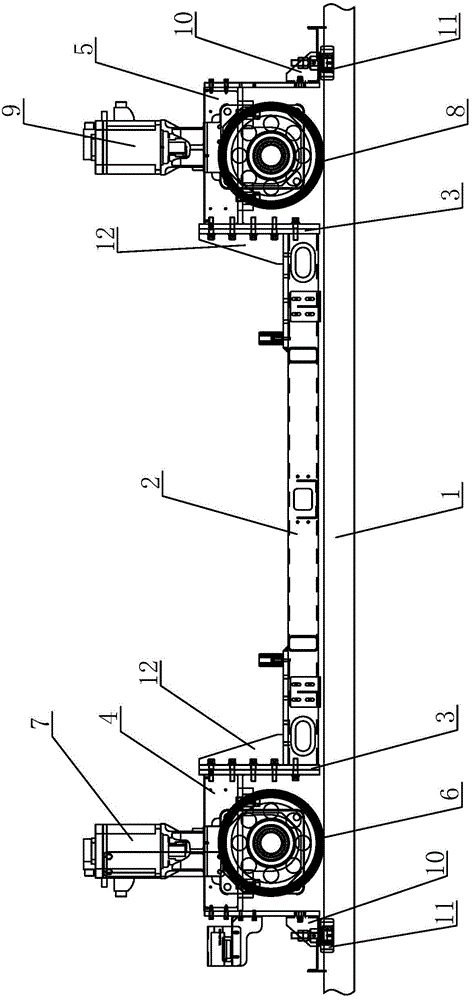

[0015] see figure 1 as shown, figure 1 It is a structural schematic diagram of the horizontal drive mechanism of the dual-drive stacker provided in Embodiment 1 of the present invention.

[0016] In this embodiment, a double-drive type stacker horizontal driving mechanism includes a track 1 and a stacker running mechanism arranged on the track 1, wherein the stacker running mechanism includes a lower beam 2, and the lower beam 2 The two ends of each have a first driving frame 4 and a second driving frame 5 through the connecting plate 3, the first driving frame 4 is provided with a first driving wheel 6 and a first driving motor 7, and the first driving motor 7 The first drive wheel 6 is driven to walk through the reducer, and the second drive frame 5 is provided with a second drive wheel 8 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com