A lignite column type pulsating airflow drying and dry separation synergistic upgrading equipment and method

A technology of pulsating airflow and upgrading equipment, applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of high-efficiency upgrading, inability to realize lignite drying and dry separation at the same time, single, etc., to prolong the drying time and avoid the problem of spontaneous combustion , the effect of high wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

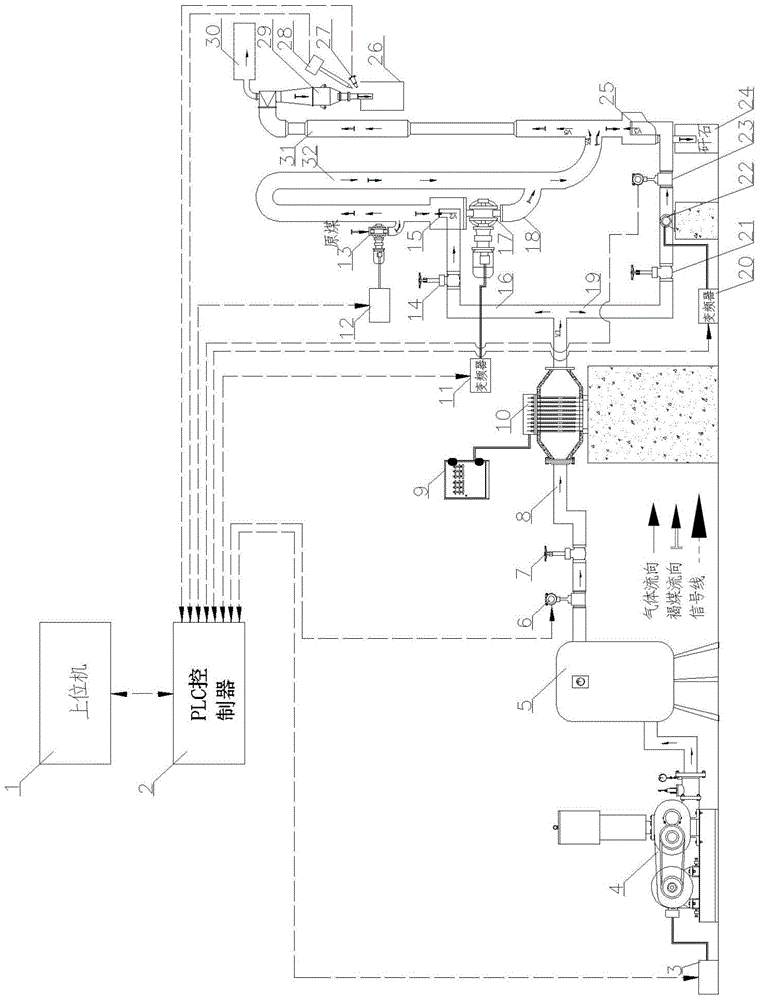

[0049] A lignite column-type pulsating airflow drying and dry separation synergistic upgrading equipment, including a drying airflow and pulsating separation mechanism and a lignite dry dry separation synergistic upgrading mechanism;

[0050] The dry air flow and pulsation separation mechanism includes: frequency converter-3, blower 4, gas storage tank 5, ventilation pipe 8, gas flow meter-6, manual valve-7, electric control cabinet 9, electric heater 10. Manual valve 2 14, upper branch pipe 16, material receiving pipe 18, lower branch pipe 19, inverter 4 20, pulse valve 22, gas flow meter 2 23, drying column 32, sorting column 31, PLC controller 2 , host computer 1; air outlet of blower 4 is connected with gas storage tank 5, PLC controller 2 output terminal is connected with the control end of blower 4 through frequency converter-3; gas storage tank 5 is connected with gas flow rate through ventilation pipe 8 Meter 16 and manual valve 17 are connected, gas flow meter 16 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com