Stepping teeth type self-staggered internal corner template

An internal corner formwork and staggered seam technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve slag inclusion, necking, easy Slurry leakage, necking and other problems, to achieve the effect of reducing material waste, eliminating slag inclusion, and high mold support efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the description.

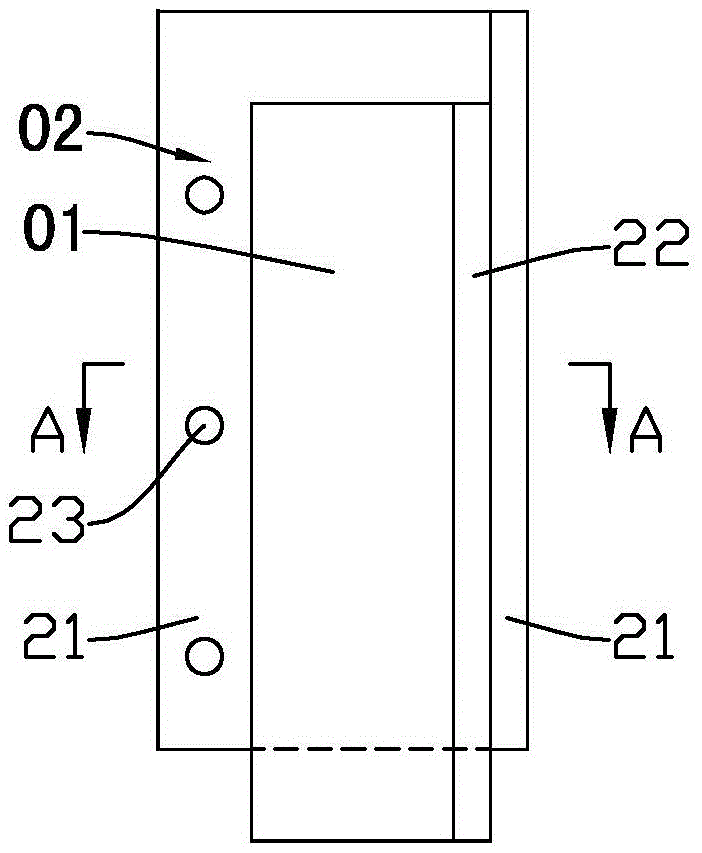

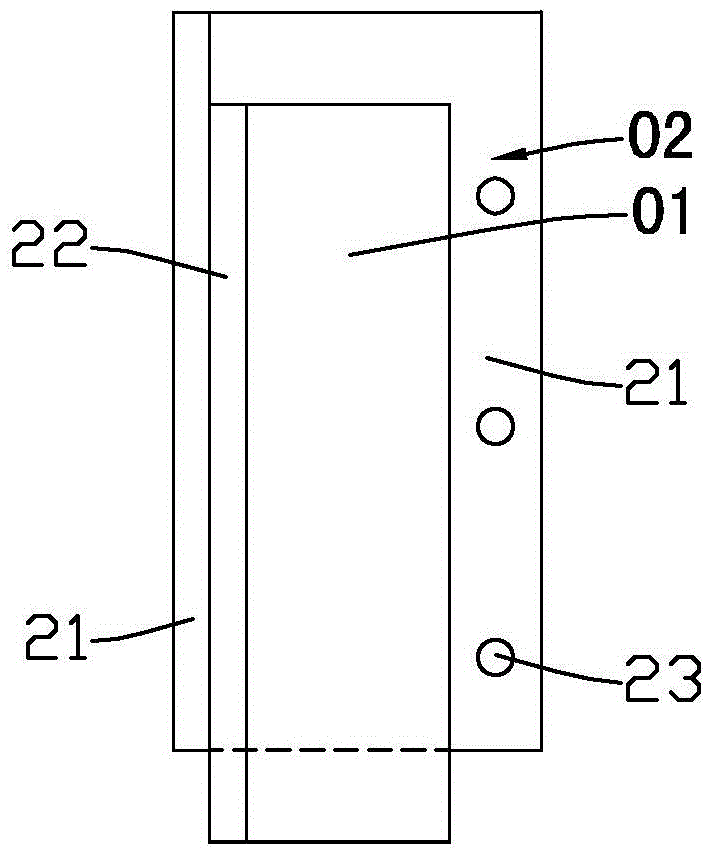

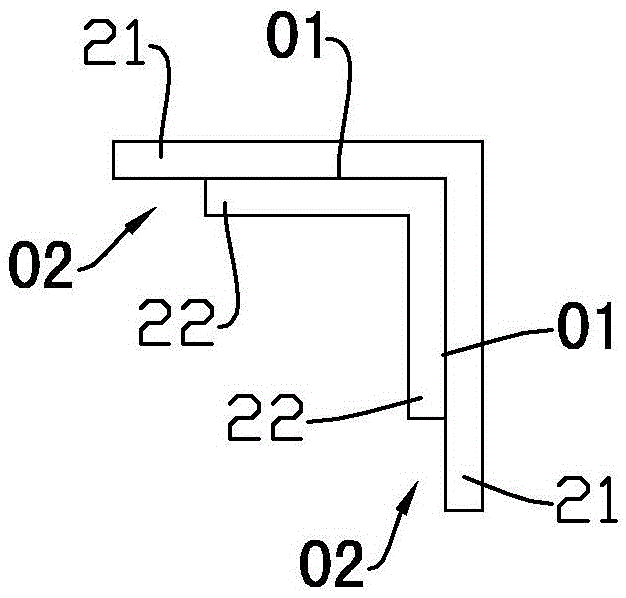

[0033] Such as Figure 1-4 As shown, the stepped tooth frame type self-staggered internal corner formwork of the present invention is a right-angled whole board made of plastic including two right-angled sides 01, and a stepped toothed frame 02 and a stepped side are respectively arranged inside the two right-angled sides. Yacha 02 refers to the step shape formed by setting a staggered edge 21 and a staggered step 22 higher than the staggered edge within the thickness range of the right-angled side 01, and the staggered steps 22 on the two right-angled sides 01 are connected It is at right angles and is located inside the angle of the whole board at right angles. The thickness T of the staggered seams and the step height H of the staggered steps are 1 / 2 of the thickness of the right-angled sides, and the thickness of the right-angled sides is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com